At GN Separation, we pride ourselves on delivering advanced solutions for waste management, and our GN Oily Sludge Treatment System is a prime example of our innovative capabilities. This system is designed to handle the complete treatment process of oily sludge through a hot washing method, providing a comprehensive and efficient approach to managing oily waste.

- Details

-

Published: 24 May 2024

During the dredging of rivers and lakes, the accumulation of various forms of debris and silt is inevitable. The separation of dredged waste and sludge demands sophisticated classification and separation equipment. At GN Separation, we offer comprehensive solid-liquid separation solutions tailored to this exacting task.

- Details

-

Published: 17 May 2024

Welcome to GN Solids Control Tangshan Factory during the beautiful spring season!

Spring is a time of renewal and growth, and it is the perfect moment to visit our factory and witness the production of high-quality solids control equipment. GN Solids Control Tangshan Factory is a leading manufacturer of solids control systems, desanders, desilters, mud cleaners, shale shakers, and other related drilling fluids processing equipment.

During your visit, you will have the opportunity to see our advanced manufacturing processes and technologies. Our skilled team of engineers and technicians work diligently to ensure that each piece of equipment meets the highest standards of quality and performance.

In addition to our manufacturing capabilities, we also pride ourselves on our commitment to customer service. Our team of experts will be on hand to answer any questions you may have about our products or the drilling industry in general. We understand that every drilling project is unique, and we are committed to providing customized solutions that meet your specific needs.

So, if you are planning a trip to Tangshan during the spring season, we invite you to come and visit GN Solids Control Tangshan Factory. We look forward to the opportunity to show you what we do and how we can help you achieve your drilling goals.

- Details

-

Published: 28 April 2024

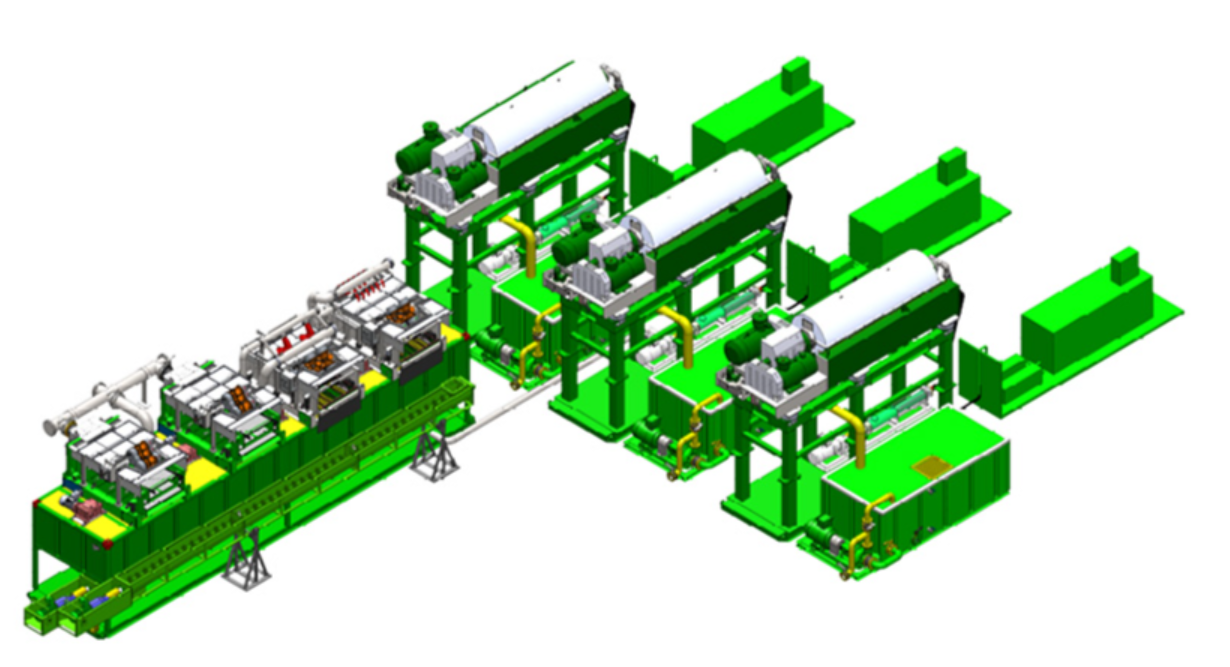

Recently, GN has completed the facbircation of 5M3 oil sludge system. Following the final factory assembly and testing, the system will be transport the overseas custommers.

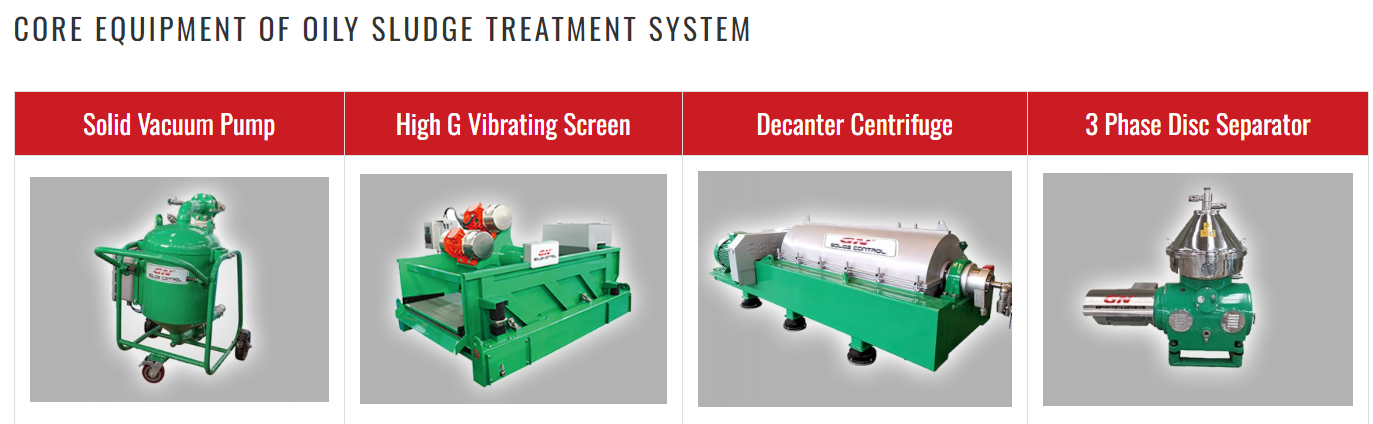

The configuration you've provided includes several key components tailored for effective oily sludge treatment:

Premixing Tank: This tank is where the oily sludge is initially collected and mixed with chemicals. The chemicals aid in breaking down the emulsions and separating the oil, water, and solids more efficiently.

GNZS706 Fine Shaker: This fine shaker serves as the primary solids control equipment, removing larger solids from the sludge mixture. It utilizes vibrating screens to separate solids of different sizes from the liquid phase.

GNLW364 Three-Phase Decanter Centrifuge: This centrifuge is a crucial component for separating the sludge into its three main components: oil, water, and solids. The decanter centrifuge achieves this separation through high-speed rotation and differential centrifugal forces.

Containerized Chemical Dosing System: The containerized chemical dosing system contains the necessary equipment for accurately dosing chemicals into the sludge mixture. These chemicals aid in destabilizing emulsions, enhancing separation efficiency, and treating the sludge for disposal or further processing.

The combination of these components provides a comprehensive solution for treating oily sludge, effectively separating its constituents for proper disposal or reuse. Additionally, the containerized design of the chemical dosing system offers portability and ease of installation, making it suitable for various applications and locations, including remote or temporary sites in the Middle East.

For more informaiton about oil sludge system, please feel free to contact GN.

- Details

-

Published: 14 April 2024

In the realm of wastewater treatment, where the challenges of separating fine particles loom large, GN Separation emerges as a beacon of efficiency with its innovative Chemical Dosing Units. Specialized in crafting cutting-edge solutions for wastewater management, GN Separation's Chemical Dosing Units stand as integral components within their comprehensive Dewatering Systems.

- Details

-

Published: 12 April 2024