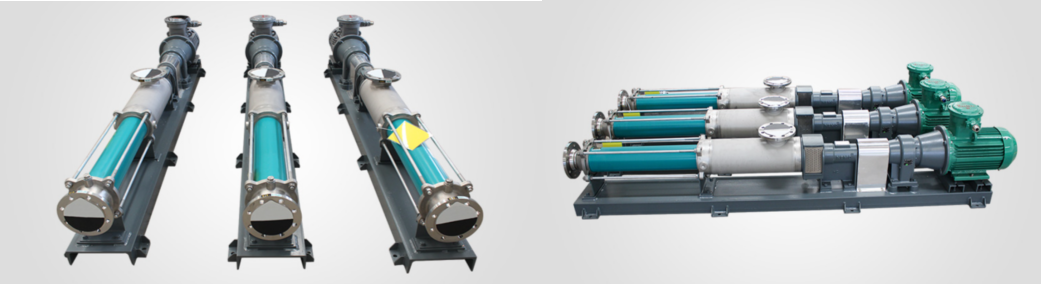

Introduction: The GNG series Progressive Cavity Pump, also known as a single screw pump, stands as a cornerstone in GN Separation's array of innovative separation solutions. With its unique design and exceptional performance, this pump plays a crucial role in various applications, particularly in feeding decanter centrifuges for efficient material separation.

- Details

-

Published: 21 February 2024

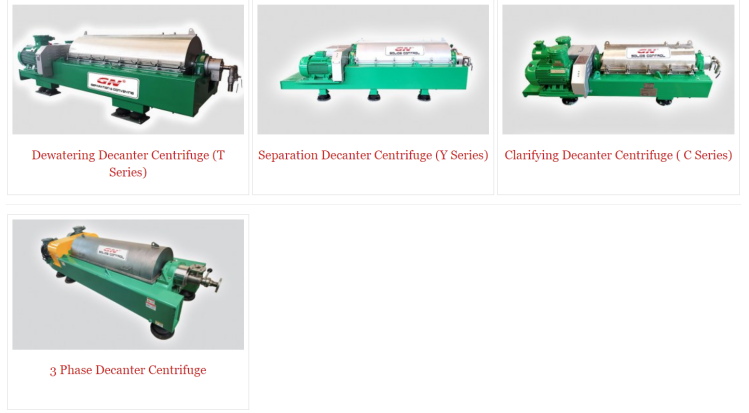

With the continuous development of technology and industrialization, various advanced separation equipment are gaining more attention and applications across different industries. Among them, the GN Separation Decanter Centrifuge, as an efficient, flexible, and reliable separation device, finds wide applications in multiple sectors. This article will introduce the applications of the GN Separation Decanter Centrifuge in industries such as chemical, pharmaceutical, food, and environmental protection, exploring its advantages and development trends in different fields.

- Details

-

Published: 21 February 2024

A sludge vacuum pump operates by creating a vacuum or suction that effectively pulls the sludge into the pump and transfers it to a desired location for further processing, disposal, or treatment. These pumps are often equipped with robust construction and specialized features to handle the demanding nature of sludge, such as:

High Solids Handling Capability: Sludge vacuum pumps are designed to handle high concentrations of solids found in sludge, preventing clogging and ensuring efficient transfer.

Abrasion Resistance: Sludge pumps are constructed with materials that can withstand the abrasiveness of the sludge, extending the pump's lifespan and reducing maintenance requirements.

Self-Priming: Many sludge vacuum pumps are self-priming, meaning they can automatically create suction and lift the sludge without the need for additional priming.

Variable Flow and Pressure: These pumps are often adjustable for flow rate and pressure, allowing for flexible operation based on the specific requirements of the application.

Please contact GN to get more information about the sludge vacuum pump.

- Details

-

Published: 05 February 2024

About GN SeparationGN Separation

We are a specialized company committed to the field of decanter centrifuges, boasting rich experience and excellent technical capabilities. We aim to provide efficient and reliable centrifugal separation solutions, catering to various needs in liquid-solid and solid-liquid separation across industries.

- Details

-

Published: 25 January 2024

The GN decanter centrifuge is a high-performance solid-liquid separation equipment used in various industries, including oil and gas drilling, wastewater treatment, and chemical processing. It is designed to separate solid particles from liquid suspensions by utilizing centrifugal force.

The GN decanter centrifuge operates on the principle of sedimentation, where the centrifugal force generated by the rotating bowl causes the denser solid particles to settle at the bowl's wall while the lighter liquid phase forms a clarified layer in the center. This separation process is highly efficient and can achieve a high degree of solid-liquid separation.

The GN decanter centrifuge offers several key features that contribute to its effectiveness and reliability. Firstly, it has a robust construction with high-quality materials, ensuring durability and long service life even in demanding operating conditions. The bowl and conveyor scroll are made from stainless steel, providing resistance to corrosion and wear.

Secondly, the GN decanter centrifuge has adjustable parameters such as bowl speed and differential speed, allowing operators to optimize process based specific characteristics of the feed material. This flexibility ensures efficient and precise separation for various applications.

Additionally, the decanter centrifuge is equipped with a reliable drive system that ensures smooth and stable operation. It has advanced control systems that monitor and operating parameters automatically, performance and reducing the need for manual intervention.

The GN decanter centrifuge is designed for easy maintenance and cleaning. It features a user-friendly interface and accessible components, allowing for convenient operation and troubleshooting. The centrifuge also has a compact footprint, making it suitable for installations with limited space.

In conclusion, the GN decanter centrifuge is a versatile and efficient solid-liquid separation equipment. Its reliable performance, adjustable parameters, and user-friendly design make it a very famous brand in both aborad and demostic.

To get more information, please feel free to contac GN immediately.

- Details

-

Published: 21 January 2024

GN decanter centrifuge is a type of industrial equipment used for solid-liquid separation, particularly in the oil and gas, drilling, and wastewater treatment industries. It is designed to separate solid particles from the liquid phase by using centrifugal force.

The GN decanter centrifuge consists of a rotating bowl, a screw conveyor, and a driving system. The liquid-solid mixture is fed into the bowl, where the centrifugal force causes the heavier solid particles to settle on the inner wall of the bowl. The screw conveyor then moves the settled solids towards the conical end of the bowl, where they are discharged.

GN decanter centrifuges are known for their high performance and reliability. They can handle a wide range of materials with varying particle sizes and concentrations. The equipment is typically made of high-quality stainless steel, which ensures durability and resistance to corrosion.

GN offers a range of decanter centrifuges with different specifications to meet various operational requirements. These include different bowl sizes, bowl speeds, and conveyor designs. Some models also feature advanced control systems for precise operation and monitoring.

It is important to consult the specific technical specifications and capabilities of the GN decanter centrifuge models available, as they can vary depending on the application and customer requirements. Detailed information about the GN decanter centrifuge product line can be found on the GN Solids Control website or by contacting their sales representatives.

- Details

-

Published: 14 January 2024