- Details

-

Published: 27 May 2025

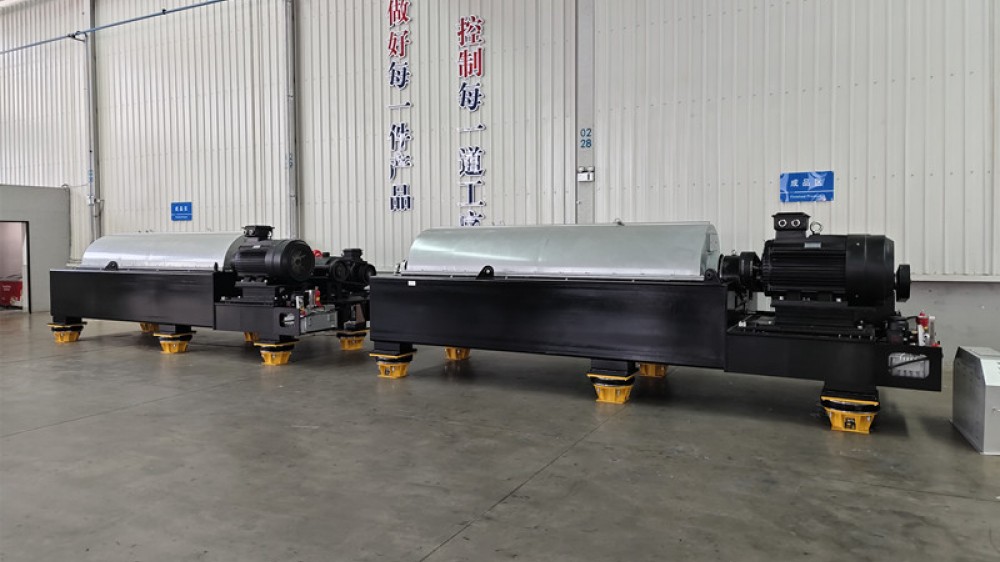

GN Separation has recently manufactured and delivered three units of its GNLW764 decanter centrifuges to a European sugar processing plant. These high-capacity machines, specifically engineered for dewatering processes, are set to be instrumental in managing the wastewater produced during sugar beet washing operations.

Role of Decanter Centrifuges in Sugar Beet Processing

The washing of sugar beets is a process that consumes significant amounts of water, resulting in the generation of large quantities of wastewater contaminated with sludge. If this wastewater is not treated, it can lead to environmental hazards and increased costs for sugar manufacturers. Decanter centrifuges, like GN Separation's GNLW764, are designed to effectively separate solids from liquids, thereby reducing the volume of wastewater and facilitating the reuse of water. By treating the effluent from beet washing, these centrifuges assist sugar processors in adhering to environmental standards, cutting down on water usage, and enhancing the sustainability of their operations.

Notable Features of GN Separation’s GNLW764 Decanter Centrifuges

The GNLW764 stands as GN Separation's largest independently developed dewatering decanter centrifuge, designed for high-volume sludge dewatering in sectors such as agriculture, mining, and tunneling. Its standout features include:

-

Duplex Stainless Steel Bowl with Centrifugal Casting

The centrifuge's bowl, or "drum," is constructed from duplex stainless steel using centrifugal casting techniques. This method guarantees uniform material density, preventing internal flaws and ensuring dynamic stability at high rotational speeds. Consequently, the centrifuge operates smoothly and vibration-free, prolonging its service life and minimizing maintenance requirements. -

Tungsten Carbide-Enhanced Screw and Discharge Port

To endure the abrasive effects of solids, the screw's flights are reinforced with tungsten carbide wear plates, and the discharge port is shielded by a tungsten carbide sleeve. These materials, renowned for their exceptional hardness and resistance to corrosion, reduce downtime due to component wear and tear, ultimately lowering long-term operational expenses. -

Automated Oil Lubrication System for Main Bearings

The GNLW764 incorporates an automated oil lubrication system for its main bearings, providing consistent lubrication under diverse load conditions. This automation streamlines maintenance procedures, mitigates the risk of human error, and bolsters reliability—essential attributes for uninterrupted operations in challenging industrial settings.

Versatile Applications Beyond Sugar Beet Processing

Although the GNLW764 demonstrates exceptional performance in sugar beet wastewater treatment, its robust construction and high processing capacity also make it suitable for other industries that require large-scale sludge dewatering, such as mining tailings dewatering, sewage sludge dewatering, and tunneling mud recycling.

For further details regarding dewatering centrifuges, please do not hesitate to reach out to GN Separation.