Decanter centrifuges are indispensable in the field of industrial solid-liquid separation, and among the many models available, the GNLW364 Decanter Centrifuge stands out for its exceptional performance and quality. Recently, this model has been selected for an overseas crystal salt dewatering project, further solidifying its reputation as a top-tier solution in this domain.

- Details

-

Published: 21 June 2024

The GNDL303 Screw Press is manufactured from high quality materials including 304 stainless steel. This ensures durability and corrosion resistance, making it suitable for the demanding conditions of municipal sludge treatment plants.

One of the outstanding features of the GNDL303 Screw Press is its Variable Frequency Drive (VFD). This allows the operator to adjust the speed of the screw, thus providing the flexibility to adapt to different sludge concentrations and flow rates. By optimising the dewatering process, it helps to minimise energy consumption while maximising efficiency.

In addition, the GNDL303 Screw Press is designed with PVC pipework connections in accordance with US standards. This allows for seamless integration into existing pipework and ensures compliance with local regulations. As a result, installation time and costs are reduced while operational efficiency is increased.

Eventually, the GNDL303 Screw Press is a reliable and efficient solution for municipal sludge dewatering in the USA. With its durable construction, adjustable speed control and strict adherence to US standards, it is perfectly suited to meet the specific requirements of US municipal sludge treatment facilities.

- Details

-

Published: 16 June 2024

In the realm of municipal sludge dewatering, GN Separation presents an innovative and environmentally friendly solution: the GNDL303 Screw Press. This state-of-the-art machine is designed to efficiently and economically handle sludge dewatering, making it an ideal choice for municipalities looking to improve their wastewater treatment processes.

- Details

-

Published: 14 June 2024

Decanter centrifuges are widely used in various industries such as oil and gas, chemical, food, and wastewater treatment. For overseas customers, decanter centrifuges can be designed and manufactured to meet specific requirements and regulations.

Key Features of Decanter Centrifuges for Overseas Customers:

High-efficiency separation: Decanter centrifuges can separate solid-liquid mixtures with high efficiency, resulting in high-quality products and reduced waste.

Customized design: Decanter centrifuges can be customized to meet specific requirements of overseas customers, including different sizes, materials, and configurations.

Corrosion-resistant materials: Decanter centrifuges can be made from corrosion-resistant materials such as stainless steel, titanium, or other alloys to withstand harsh environments.

Explosion-proof design: Decanter centrifuges can be designed to meet explosion-proof requirements for hazardous environments.

Easy maintenance: Decanter centrifuges are designed for easy maintenance, with features such as easy access to components, simple cleaning, and minimal downtime.

Compliance with international standards: Decanter centrifuges can be designed and manufactured to comply with international standards and regulations, such as API, ASME, and CE.

Applications of Decanter Centrifuges for Overseas Customers:

Oil and gas industry: Decanter centrifuges can be used for drilling mud treatment, oil refining, and petrochemical processing.

Chemical industry: Decanter centrifuges can be used for chemical processing, wastewater treatment, and sludge dewatering.

Food industry: Decanter centrifuges can be used for food processing, beverage production, and dairy processing.

Wastewater treatment: Decanter centrifuges can be used for municipal and industrial wastewater treatment, sludge dewatering, and biosolids processing.

Mining industry: Decanter centrifuges can be used for mineral processing, tailings treatment, and wastewater treatment.

- Details

-

Published: 10 June 2024

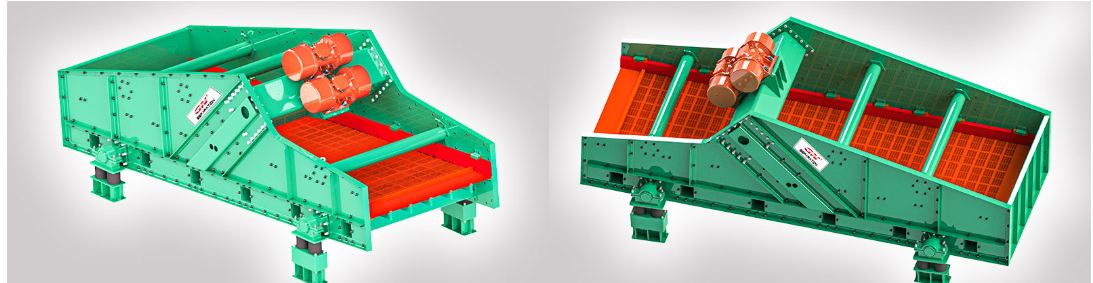

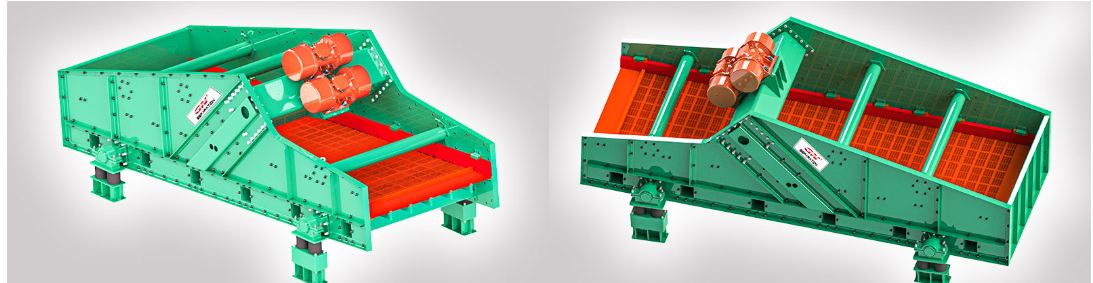

GN Separation is proud to introduce the GN Classification Vibrating Screen, a state-of-the-art solution for the classification and screening of various materials such as iron ore, coal, non-ferrous metal ore, building materials, and chemicals. Our equipment incorporates advanced design techniques like finite element analysis and anti-fatigue analysis to ensure a robust structure, low energy consumption, and high screening and classification capacity.

Versatile Applications

The GN Classification Vibrating Screen is ideal for a wide range of industries, handling materials that are prone to corrosion and wear. Its applications span from iron ore and coal to non-ferrous metal ores and building materials, making it a versatile choice for various working conditions. The equipment boasts large processing capacity, high efficiency, and stable performance.

Customizable Design

One of the key features of the GN Classification Vibrating Screen is its customizable size. The equipment can be tailored to meet the specific requirements of customers, ensuring optimal performance for each unique application.

Linear Motion Principle

The screen utilizes two vibrating motors installed on the body, which move in a linear line based on the principle of reverse self-synchronization. This linear motion drives the screen panel to vibrate synchronously, transmitting force to the materials on the panel. The materials are then thrown up on the screen surface, layered, and screened according to the specified particle size.

Efficient Screening Process

Materials are continuously fed from the feeding trough to the receiving plate, where they are screened and graded through the screen surface. The screened materials are then discharged into the receiving trough above and below the screen, ready for the next processing stage. The angle between the vibration force direction and the horizontal direction can be adjusted according to the material properties, influencing the running speed of materials on the screen surface and the processing capacity of the equipment.

Technical Characteristics and Advantages

- Non-Welded Wallboard: Made from steel plates with excellent impact toughness and cold bending properties, assembled using imported HUCK rivets for hydraulic tension. This design eliminates welding residual stress and material defects, enhancing fatigue strength.

- Finite Element Analysis: Optimizes structural strength and vibration quality, reducing stress and extending equipment life.

- Polyurea Spraying: Fluid-contact parts and easily worn areas are sprayed with polyurea for superior corrosion, erosion, and wear resistance.

- Post Weld Heat Treatment: Effectively eliminates welding stress in main components.

- Modular Design: Polyurethane screen panels are modular, versatile, and easy to replace, meeting various manufacturing requirements.

- Adjustable Installation Angle: The machine is installed at a positive inclination angle, adjustable by 4 degrees to suit different process materials.

- Enhanced Screening Area: The flat design of the screen surface maximizes the effective screening area, improving material classification.

- Rubber Damping Spring: Features good damping effect, low noise, small resonance field, excellent resilience, stable mechanical performance, long service life, and low cost.

Final Note

The parameters provided are for reference only and can be adjusted according to the customer's specific situation. The final quotation and technical agreement will prevail. The handling capacity of materials with the same size can vary significantly under different working conditions. For more detailed information and to discuss your specific requirements, please consult GN Separation.

GN Separation is committed to delivering innovative and reliable solutions for all your classification and screening needs. Contact us today to learn more about the GN Classification Vibrating Screen and how it can benefit your operations.

- Details

-

Published: 07 June 2024

We at GN Separation are thrilled to announce the shipment of our 22-inch large decanter centrifuge to an overseas client. This marks another milestone in our commitment to providing cutting-edge separation technology to clients around the globe.

- Details

-

Published: 03 June 2024