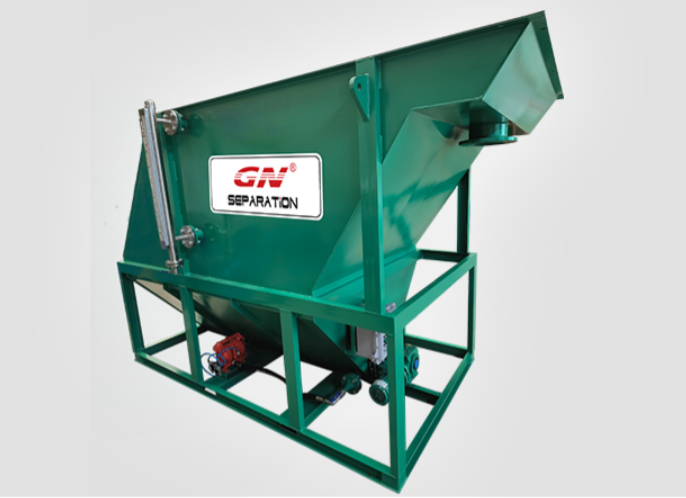

At GN Separation, we are committed to providing advanced, efficient solutions for liquid and solid separation across various industries. One of our key offerings is the Slant Plate Clarifier, also known as the Inclined Plate Clarifier. This innovative piece of equipment is designed to optimize the separation of solids from liquids in a wide range of applications, delivering superior performance in a compact footprint.

- Details

-

Published: 18 October 2024

GN oil sludge system is to use chemical to wash the oil sludge with heat to temperature of 60-70 degree. After washing the sludge wil be pump to GN sepeartion equipment to do solid and liquid separtion. The recycled water can be reused in the washing process, and the oil is clean enough to sell to the refinery company, the solids contain less than 2% oil which can be sent to biodegradation or thermal unit for final disposal if needed.

Recently GN have completed a small oil sludge system, It will be sent to oversea customers soon. GN have 2 different model, namely GNOST-05C and GNOST-15C for the oil sludge system according to diggerent handling capacity. The GNOST-05C is an advanced oil sludge treatment system designed for efficient and effective processing of oil sludge. It utilizes cutting-edge technology to separate oil, water, and solids, ensuring compliance with environmental standards.

The oil sludge system is meticulously engineered with a GNLW364FT decanter centrifuge, a chemical dosing system, and a mud feed screw pump, all housed within standard containers for enhanced transportation efficiency and ease of installation. This innovative packaging approach significantly boosts the maintainability and protection of the equipment, ensuring a long service life and minimal downtime.

Treatment Processes

heating and Pre-mixing module

There is a pre-mixing tank for the preparation of the material and then heat the material to 60-70 degree.

Screening module

There is vibration screen in this module, in order to remove the corase particle there, and feed in the fine particule to the next module directly.

Chemical dosing unit

add some polymer here to help the decanter to make the solid and liquid separation more efficient.

Decanter centifuge module

The material will be feed in the 2-phase decanter centifuge at first to do the solid liquid sepation, and then the separated liquid will be feed into the 3-phase decanter centrifuge to get the oil-water-solid separation.

If you need more specific information or have particular questions about oil sludge systems, feel free to contact GN.

- Details

-

Published: 17 October 2024

GN Separation has successfully delivered 3 sets of GNLW654-VFD decanter centrifuges to support a municipal wastewater treatment project in a North African country. This project not only includes the installation of the dewatering centrifuges but also features a 6500L chemical dosing unit, ensuring high precision and efficiency in the sludge treatment process.

- Details

-

Published: 12 October 2024

Wastewater treatment decanter centrifuge is a device used to separate solid and liquid components of wastewater. It separates solids from liquids in the mixture by centrifugal force and is widely used in municipal wastewater treatment, industrial wastewater treatment and other fields.

Main advantages

High efficiency: enables fast and effective separation of solids and liquids, increasing treatment efficiency.

Small footprint: Compared to traditional settling tanks, centrifuges have a smaller footprint, making them suitable for sites with limited space.

High degree of automation: many modern centrifuges are equipped with automated control systems, reducing the need for human intervention.

Areas of application

Municipal wastewater treatment: used to treat sewage discharged from cities to reduce environmental pollution.

Industrial wastewater treatment: treatment of wastewater generated by various industries (e.g. chemical, food, pharmaceutical, etc.).

Recycling: The separated solids and liquids can be further processed and recycled to reduce the waste of resources.

Maintenance and Precautions

Regular inspection: Ensure the normal operation of the equipment to avoid failure due to wear and tear or blockage.

Operator Training: Operators need to receive professional training to ensure safety and efficiency.

Wastewater treatment centrifuges play an important role in modern wastewater treatment systems, contributing to environmental protection and resource reuse through efficient separation technology.

For more information. pls feel free to contact GN.

- Details

-

Published: 12 October 2024

The working principle of solid vacuum pump is mainly powered by compressed air, using vacuum suction loading and pneumatic positive pressure to convey materials. Crown's solid vacuum pumps are powered entirely by compressed air and are capable of conveying solid particles, powdered materials, slurries, highly concentrated sludge, oil-containing sludge, mineral slurries, and other bulk materials, etc.

The working principle of solid vacuum pump can be divided into the following steps:

Suction process: In the suction process, the volume inside the pump chamber increases, forming a low-pressure area, making the external solid material is sucked into the pump chamber.

Compression process: as the pump chamber volume decreases, the material is compressed, the pressure gradually increases.

Exhaust process: when the pressure in the pump chamber reaches a certain level, the material is discharged out of the pump through the exhaust port, completing a working cycle.

The main application areas of solid vacuum pumps include:

Conveying solid particles and powder materials: it is suitable for conveying all kinds of solid particles and powder materials, such as mineral slurry and high concentration sludge.

Environmental protection field: in sewage treatment and sludge treatment, solid vacuum pumps can effectively transport oily sludge and other bulk materials.

Industrial production: in the production process of chemical, food, pharmaceutical and other industries, solid vacuum pumps are used for material conveying and loading to improve production efficiency

- Details

-

Published: 06 October 2024

In the global industrial separation sector, GN Separation's GNLW364GT-FHD hydraulic drive decanter centrifuge stands out with its advanced design and excellent separation performance, making it the ideal choice for a variety of industries. This food-grade centrifuge features a polished bowl inner surface and screw to prevent material residue, meeting strict hygiene standards. Additionally, it is equipped with temperature and vibration sensors, an automatic lubrication system, and a hydraulic system from the internationally renowned Swiss brand Viscotherm, ensuring efficient and stable long-term operation.

- Details

-

Published: 30 September 2024