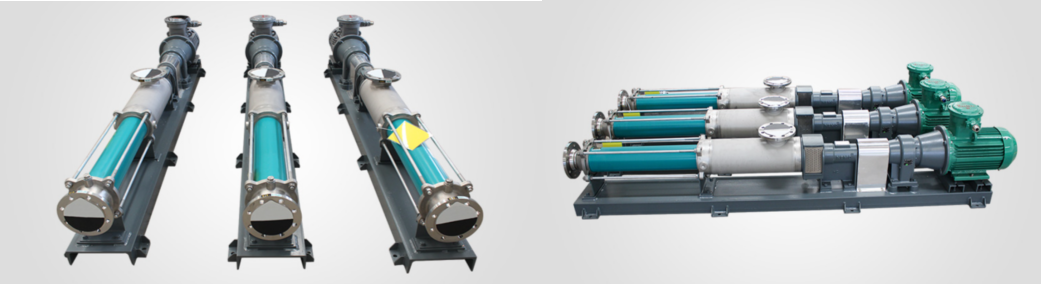

When it comes to precision pumping solutions, GN Separation is proud to introduce the GNG Series Progressive Cavity Pump, also referred to as a single screw pump. This cutting-edge pump is designed to meet the demanding needs of various industries, providing a combination of efficiency, durability, and reliability.

- Details

-

Published: 20 December 2024

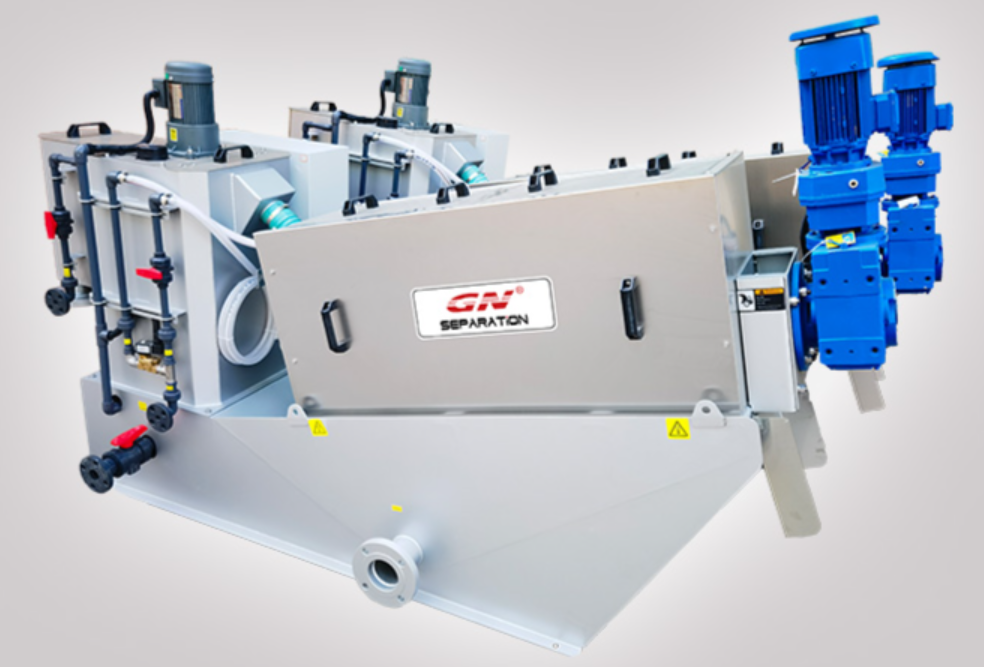

The GN Sludge Dewatering screw press Machine package is designed for European wastewater treatment plants and aims to provide an efficient and reliable sludge dewatering solution. The equipment combines advanced technology and superior performance to help the wastewater industry achieve sustainable development.

Screw press GNDL303 features and advantages

Model GNDL303 screw press Machine adopts advanced screw press technology, which is capable of efficiently dewatering sludge and significantly reducing sludge water content. Its main functions include:

Efficient dewatering: With the unique screw structure, it maximises sludge dewatering efficiency and reduces the burden of subsequent treatment.

Energy-saving and environmental protection: the equipment design is optimised for low energy consumption, which meets the requirements of environmental protection and helps sustainable development.

Automation control: Intelligent control system, real-time monitoring of operating status, to ensure efficient and stable operation of the equipment.

Dosing device GNSJY2000 features and advantages

GNSJY2000 dosing device focuses on precise dosing of chemicals to ensure the stability of water quality and treatment effect. Its main features include:

Accurate dosage: Equipped with advanced flow meters and sensors, it can accurately control the dosage of chemicals to ensure the effect of water treatment.

Easy operation: user-friendly interface design makes the operation more intuitive and reduces the technical threshold.

High safety: Built-in multiple safety protection measures to ensure the safety of equipment and operators.

Application Fields

The two devices are widely used in sewage treatment plants, industrial wastewater treatment, and municipal water treatment and other fields. Their combination not only improves the sewage treatment capacity, but also effectively reduces the operating costs, becoming an indispensable core equipment for modern sewage treatment.

Choose the GNDL303 screw stacker and the GNSJY2000 dosing unit to help your wastewater treatment process move towards greater efficiency and sustainability!

- Details

-

Published: 15 December 2024

GN Separation is proud to announce the successful deployment of its Sludge Dewatering Screw Press Package for a prominent sewage treatment plant in Europe. This comprehensive package features the GNDL303 Screw Press and the GNSJY2000 Chemical Dosing Unit, designed to provide efficient and environmentally friendly solutions for sludge dewatering.

- Details

-

Published: 13 December 2024

In the mineral processing industry, accurate classification is the key to improving product quality and productivity. GN is proud to introduce a batch High Shear Circular Vibrating Screen,, tailor-made for foreign silica sand classification projects. Our High Shear Circular Vibrating Screen use advanced vibration technology to effectively achieve particle size classification, ensuring that every silica sand meets industry standards.

Product Features and Benefits

Efficient classification: The unique design of the High Shear Circular Vibrating Screen provides uniform vibration, ensuring that the material is evenly distributed on the screen surface, thus achieving higher classification efficiency.

Strong durability: the selection of high-quality materials, wear-resistant, adapt to the harsh working environment, to extend the service life of the equipment.

Easy maintenance: modular design makes it easier to maintain and replace parts, reducing downtime and improving production efficiency.

Flexible application: suitable for screening a variety of materials, especially in the classification of minerals such as silica sand, outstanding performance.

Application areas

GN High Shear Circular Vibrating Screen is widely used in mineral processing, building materials and chemical industries, especially in foreign silica sand projects, with its excellent classification ability, helping customers achieve higher product purity and lower production costs.

Pls feel free to contact GN to get more information.

- Details

-

Published: 08 December 2024

At GN Separation, we are proud to introduce the GN Synergistic Frequency Vibrating Screen, a self-developed product that represents a breakthrough in fine material screening. Designed with a combination of linear vibration and partial electromagnetic vibration frequencies, this innovative solution is tailored for high-efficiency screening, grading, and separation across various industries such as coal, metallurgical mineral processing, chemicals, ceramics, and more.

- Details

-

Published: 29 November 2024

- GN 2025- Stay Together, Power the Future

- Sewage Treatment Slant Plate Clarifier and Screw Press for Overseas Client

- GN Decanter Centrifuge Successfully Installed and Commissioned in French STP

- Successful Installation and Commissioning of GN Dewatering Decanter Centrifuge at a Municipal Wastewater Treatment Plant in France

- Mini Decanter Centrifuges Delivered to Europe