PART 1: COLLECTIVE DEDICATION SPARKS PERFORMANCE LEAP

2024 marked a remarkable leap in GN's performance, fueled by the unwavering dedication of each team member. Our mining vibrating screens saw significant sales and widespread application. Numerous hydraulic centrifuges were sold to offshore drilling platforms across the globe. Over 20 solids control systems for oil and gas drilling rigs found new homes, while more than 80 sets of various mud treatment systems left our production lines. The year concluded with a 30% year-on-year revenue increase, a testament to the tireless efforts of the entire GN family.

PART 2: INNOVATION-LED R&D BEARS FRUITFUL RESULTS

In acknowledgment of our commitment to innovation, GN was honored with the esteemed "National Key Small Giant Enterprise" title in 2024. Our R&D endeavors yielded two new invention patents and four utility model patents. The successful development and sale of the Tracked Mounted Mud System to Australia, the Core Drilling Hydraulic Centrifuge internationally, and the Synergistic Frequency Vibrating Screen to the mining market underscore our dedication to craftsmanship and research. GN's investment in R&D has undeniably paid dividends, positioning us as a leader in the industry.

PART 3: EQUIPMENT INVESTMENTS BOOST PRODUCTION CAPACITY

To meet the escalating demand, GN invested in cutting-edge equipment, significantly augmenting our production capacity. We added a new 30,000-watt large-scale CNC laser cutting machine capable of cutting 45mm thick plates to our collection. The new welding robot production line for solids control equipment has been operationalized, and additional CNC lathes accommodated the heightened production of centrifuges. Furthermore, a large-scale painting workshop has been established for the manufacturing of large mud tanks, and a spacious outdoor yard has been designated for the assembly and testing of large mud systems. We also inaugurated a new 1,500-square-meter exhibition hall dedicated to showcasing our separation equipment. With expanded production areas and intelligent manufacturing equipment, GN's production capacity has seen a substantial upgrade, enabling us to fulfill diverse customized orders from clients worldwide.

PART 4: GLOBAL PRESENCE – SEPARATION EQUIPMENT SERVING THE WORLDWIDE COMMUNITY

GN's brand, manufacturing, and equipment continued to shine on the global stage in 2024. We participated in pivotal industry exhibitions, including the CIPPE Exhibition in Beijing in March, the IE Expo in Shanghai in April, the OTC Oil & Gas Exhibition in America in May, the Expomina Mining Show in Peru in September, the IMARC Mining Exhibition in Australia in October, and the ADIPEC Oil & Gas Exhibition in the Middle East in November. Our presence at these events reaffirmed GN's standing as a leader in the separation equipment industry.

Persevering in innovation, we explore boundless possibilities; inheriting excellence, we forge the lifeblood of our brand. With foresight and ambition, we remain unified as a singular team, working towards a common dream. GN in 2024 has been a year of victory and evolution, and we eagerly anticipate continuing this journey of growth and triumph

- Details

-

Published: 02 February 2025

With its headquarters in China and a worldwide outlook, GN has remained steadfast in its dedication to innovating, researching, and developing separation equipment and integrated systems. Guided by our mission, "Separation Creates Value," we uphold the principles of technological innovation, efficient manufacturing, and customer satisfaction. In 2024, GN united as One Team with One Dream, striving for excellence and establishing ourselves as a world-class brand.

PART 1: COLLECTIVE EXCELLENCE BOOSTS PERFORMANCE

In 2024, GN's performance saw a remarkable surge, driven by the exceptional efforts of every team member. Our mining vibrating screens achieved significant sales and widespread adoption. Hydraulic centrifuges were sold to numerous offshore drilling platforms globally. Over 20 solids control systems for oil and gas drilling rigs were successfully placed, and more than 80 various mud treatment systems rolled off our production lines. The year ended with a commendable 30% year-on-year revenue growth, a testament to the dedication and perseverance of the entire GN team.

PART 2: INNOVATION-LED R&D REAPS REWARDS

GN's commitment to innovation was recognized in 2024 with the prestigious "National Key Small Giant Enterprise" title. Our R&D endeavors resulted in two new invention patents and four utility model patents. The successful development and sale of the Tracked Mounted Mud System to Australia, the Core Drilling Hydraulic Centrifuge overseas, and the Synergistic Frequency Vibrating Screen to the mining industry underscore our dedication to craftsmanship and research. GN's investment in R&D has positioned us at the forefront of the industry.

PART 3: EQUIPMENT UPGRADE BOOSTS PRODUCTION CAPACITY

To cater to the increasing demand, GN invested in cutting-edge equipment, significantly enhancing our production capabilities. We added a new 30,000-watt large-scale CNC laser cutting machine capable of cutting 45mm thick plates. The new welding robot production line for solids control equipment was commissioned, and additional CNC lathes accommodated the increased production of centrifuges. Furthermore, we established a large-scale painting workshop for manufacturing large mud tanks and an outdoor yard for assembling and testing large mud systems. We also inaugurated a new 1,500-square-meter exhibition hall dedicated to showcasing our separation equipment. With expanded production areas and intelligent manufacturing equipment, GN's production capacity has undergone a significant transformation, enabling us to fulfill diverse customized orders from clients worldwide.

PART 4: GLOBAL INFLUENCE - SEPARATION EQUIPMENT SERVING THE WORLDWIDE COMMUNITY

GN's brand, manufacturing, and equipment continued to shine on the global stage in 2024. We participated in key industry exhibitions, including the Beijing CIPPE Exhibition in March, the Shanghai IE Expo in April, the American OTC Oil & Gas Exhibition in May, the Peru Expomina Mining Show in September, the Australian IMARC Mining Exhibition in October, and the Middle East ADIPEC Oil & Gas Exhibition in November. Our presence at these events reaffirmed GN's position as a leading player in the separation equipment industry.

By persevering in innovation, we explore endless possibilities. By inheriting excellence, we create the lifeblood of our brand. With foresight and ambition, we remain unified as One Team, working towards One Dream. GN's 2024 has been a year of victory and evolution, and we eagerly anticipate continuing this journey of growth and success.

- Details

-

Published: 26 January 2025

This week, GN Separation is conducting factory testing on two high-speed tubular centrifuges, model GNGQ150, destined for an overseas client's facility. These centrifuges are specifically designed for separating fermentation broths.

Operating at an impressive rotational speed of 14,000 RPM, the GNGQ150 tubular centrifuges generate a separation factor of up to 15,000G, making them highly efficient for solid-liquid separation. This process is crucial in the production of various biopharmaceuticals, enzymes, and other biological products derived from fermentation processes.

The fundamental principle behind tubular centrifuges is centrifugal force, which separates particles based on their density and size. When a mixture is fed into the rotating tube, the centrifugal force pushes heavier particles, typically solids, against the wall of the tube, while lighter particles, such as liquids, remain closer to the center. This results in the separation of components, with the clarified liquid exiting from one outlet and solids being trapped inside the bowl for later disassembly and cleaning.

The versatility and efficiency of high-speed tubular centrifuges like the GNGQ150 make them indispensable in a wide range of industries, particularly those involved in biotechnological processes. Key application areas include:

- Biopharmaceutical Production: High-speed tubular centrifuges are used to separate cells and cellular debris from fermentation broths, ensuring high-quality products such as vaccines, monoclonal antibodies, and recombinant proteins.

- Enzyme Purification: Tubular centrifuges gently and effectively purify enzymes from fermentation broths, preserving enzymatic activity and yield, which is crucial for various industrial processes.

- Microbial Harvesting: In the production of microbial biomass for applications such as biofertilizers and probiotics, high-speed tubular centrifuges offer a rapid and reliable solution for harvesting microbial cells from fermentation mediums.

- Wastewater Treatment: Tubular centrifuges can separate and concentrate pollutants or valuable by-products in wastewater generated from fermentation processes, facilitating further processing or disposal.

- Food and Beverage Industry: High-speed tubular centrifuges are employed to clarify and concentrate liquids, remove impurities, and enhance product quality in the production of dairy products, fruit juices, and other food items.

The use of stainless steel 304 for the material contact parts in the GNGQ150 model demonstrates GN Separation Systems' commitment to providing equipment that meets the highest standards of hygiene, durability, and corrosion resistance, which are essential in biological separation applications.

GN Separation remains focused on innovation, quality, and customer satisfaction, continuously pushing the boundaries of separation technology to enable clients worldwide to achieve greater success in their industries.

- Details

-

Published: 19 January 2025

At GN Separation, we are dedicated to delivering high-quality separation equipment to meet the unique needs of our clients. Recently, we completed factory testing of two units of the GNGQ150 High-Speed Tubular Centrifuge (also known as Tubular Bowl Separators) before shipping them to an overseas client. These units are designed to provide efficient solid-liquid separation in industries such as pharmaceutical, food, chemical, and biological products, making them ideal for use with fermentation broths.

- Details

-

Published: 17 January 2025

In the Middle East, soil remediation projects require efficient and reliable technologies to handle high volumes of wastewater and sludge. To meet these demands, GN Separation offers an innovative solution: the GN Containerized Sludge Dewatering Package. This solution is designed to provide efficient dewatering of contaminated soil and wastewater through a combination of cutting-edge equipment, including the GNLW654-VFD Decanter Centrifuge.

- Details

-

Published: 10 January 2025

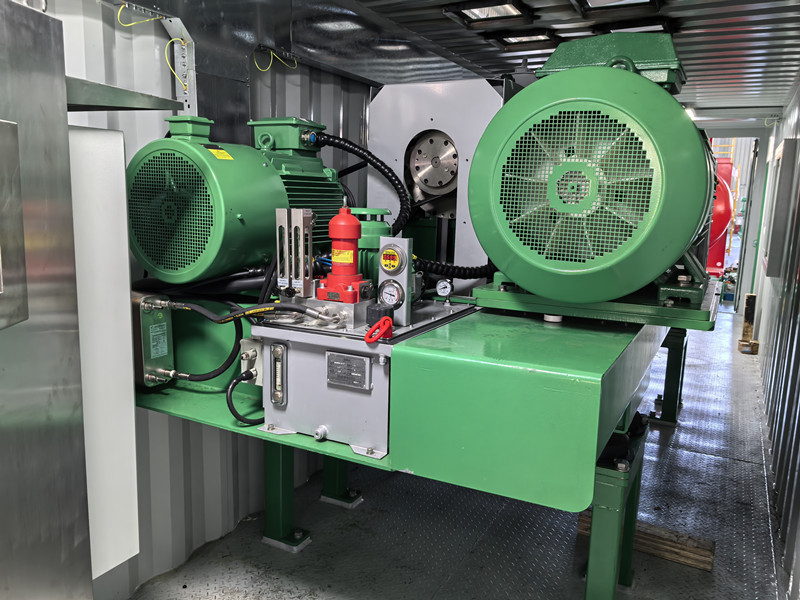

GN Containerized Sludge Dewatering Package for Soil Remediation, Packaged neatly within a standard 40ft container, the system boasts a comprehensive array of equipment tailored for exceptional mobility, straightforward installation, and robust functionality. At its core, the GNLW654-VFD sludge dewatering centrifuge, a powerhouse supplied by GN Separation and specifically tailored for this demanding application, stands out.

The GNLW654-VFD decanter centrifuge is furnished with a Variable Frequency Drive (VFD) control cabinet, a feature that offers operators unparalleled flexibility in adjusting the operational settings of the primary and secondary motors, feed pump, and polymer dosing pump. This capability allows for precise tuning of the system to accommodate varying feedstock attributes and optimize treatment efficiency, ultimately enhancing the quality of the dewatered sludge (or mud cake) while minimizing water content.

Acknowledging the severe abrasiveness of oil-tainted soil sludge, GN Separation has incorporated tungsten carbide plates and sleeves within the centrifuge's screw conveyor and slag discharge port. This strategic incorporation of wear-resistant materials not only safeguards vital components from premature wear and tear but also prolongs the overall lifespan of the equipment, thereby mitigating long-term maintenance expenses and fostering operational consistency. Complementing the centrifuge are a feed pump and dosing pump sourced from Netzsch, a reputable German manufacturer renowned for its dependable and high-performance industrial pumps. These components, integral to the system's seamless operation, guarantee precise and consistent delivery of both the sludge feed and flocculant chemicals crucial for enhancing solid-liquid separation.

The screw conveyor, another pivotal component, has been meticulously designed based on the system's intended throughput and the on-site configuration. This customized design not only facilitates smooth integration into the containerized setup but also ensures straightforward installation and user-friendly operation, which are crucial in remote and often logistically challenging environments akin to those in the Middle East.

- Details

-

Published: 10 January 2025