- Details

-

Published: 16 July 2024

GN Solids control is proud to announce the successful deployment of our Oil Sludge Treatment Decanter Centrifuge System for a client in Suriname, South America. This advanced system demonstrates our commitment to providing cutting-edge solutions for complex industrial challenges, particularly in the field of oil sludge treatment.

Decanter Centrifuge in Oil Sludge Treatment

Decanter centrifuges are indispensable in the oil sludge treatment industry due to their efficiency in separating solid and liquid phases. These centrifuges are designed to handle the challenging conditions and diverse compositions of oil sludge, making them ideal for refining processes, drilling operations, and industrial waste management.

The decanter centrifuge operates on the principle of centrifugal force, which allows for the rapid separation of solids from liquids. In the context of oil sludge treatment, the centrifuge accelerates the settling process of solid particles, thus enabling the extraction of valuable oil and reducing the volume of waste. This process not only recovers usable resources but also minimizes environmental impact.

Our Decanter Centrifuge

GN Separation offers a range of decanter centrifuges tailored to meet the specific needs of various industries. The full name of this equipment is the horizontal screw decanter centrifuge, known for its versatility and reliability in industrial solid-liquid separation. Depending on the material characteristics, GN decanter centrifuges are categorized into dewatering, separation, and clarifying types.

Features and Types of GN Decanter Centrifuges

-

T Series Dewatering Type

- Beach Angle: 8.5°

- Applicable Material Features: This type is designed for materials with large particle sizes, high-density differences between solid and liquid, low viscosity, high concentration, and high treatment capacity. It is particularly effective for sludge or wastewater containing fine particles, which often require the addition of flocculants to enhance separation.

-

Y Series Separation Type

- Beach Angle: 15°

- Applicable Material Features: Combines the benefits of dewatering and clarifying types, focusing on both liquid clarity and solid dryness. Ideal for separating fine, soft materials with small particles and low solid-liquid density differences, making it suitable for materials with high viscosity and low concentration.

-

C Series Clarifying Type

- Beach Angle: 20°

- Applicable Material Features: Best suited for materials that are difficult to separate, with small particles, moderate viscosity, and concentration. This type prioritizes the clarity of the liquid phase post-separation.

-

SX Series 3-Phase Type

- Design: Tailored for solid-liquid-liquid 3-phase separation, requiring that the solid phase is heavier than the liquid phases, which are immiscible and have different densities.

GN Decanter Centrifuge Features

As a leading manufacturer, GN prioritizes product quality and user benefits. Our centrifuges are constructed with high-quality centrifugal casting or forging stainless steel, and hard alloy protection is used for wear parts. We utilize advanced CNC lathes, centers, and gantry milling machines to ensure precision in manufacturing. Additionally, GN applies high-speed dynamic balance processes to optimize the performance of the centrifuge screw and bowl at actual working speeds.

Market Applications and Global Reach

GN decanter centrifuges are widely used across various industries and have been exported to over 60 countries, receiving high praise from clients. Our systems are integral to processes such as refining, drilling, and industrial waste management.

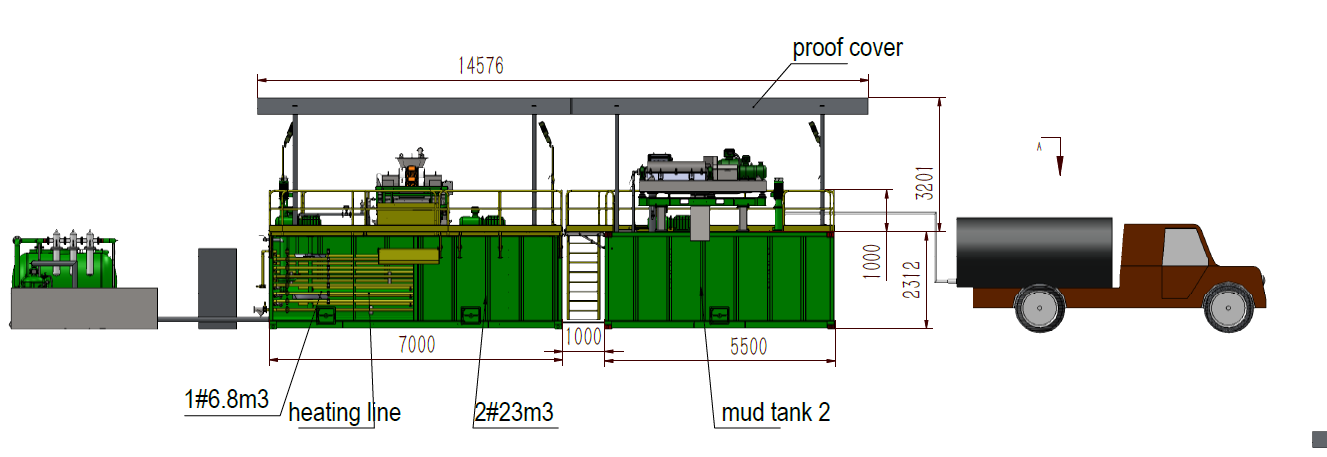

GN's Oily Sludge Treatment System

Our oily sludge treatment system provides comprehensive solutions for the entire treatment process, including extraction, heating, conditioning, coarse particle screening, sludge dewatering, and three-phase separation. This system is a chemical-assisted mechanical separation process, which includes the following steps:

- Sludge Picking Up: Extraction from the sludge pit using a GN solid vacuum pump or excavator.

- Heating & Conditioning: Pre-mixing and conditioning in a heating tank.

- Screening Treatment: Coarse particle separation using a vibrating screen.

- Secondary Heating & Conditioning: Further conditioning with chemical agents to strip oil from solids.

- Solid Liquid Separation: Two-phase decanter centrifuge separates solid sludge with low oil content.

- 3 Phase Separation: Final separation using a three-phase disc separator to obtain saleable oil and reusable water, with solids discharged for further processing.

GN’s oily sludge treatment system is applicable for oil refineries, drilling operations, tank cleaning, and industrial sludge treatment. By providing customized solutions based on client needs, GN continues to lead the industry in innovation and efficiency.

In summary, GN Separation's decanter centrifuge systems are pivotal in optimizing oil sludge treatment processes, offering robust, high-performance solutions for our clients worldwide. Our commitment to quality and customer satisfaction ensures that our products not only meet but exceed industry standards.