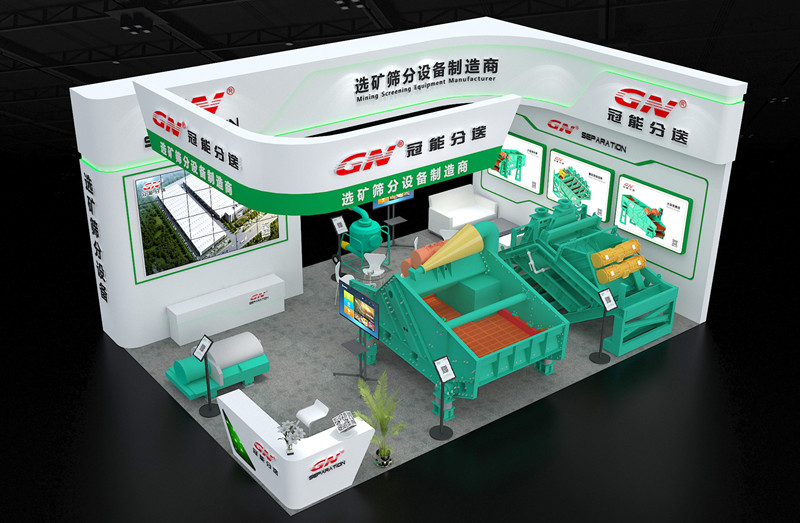

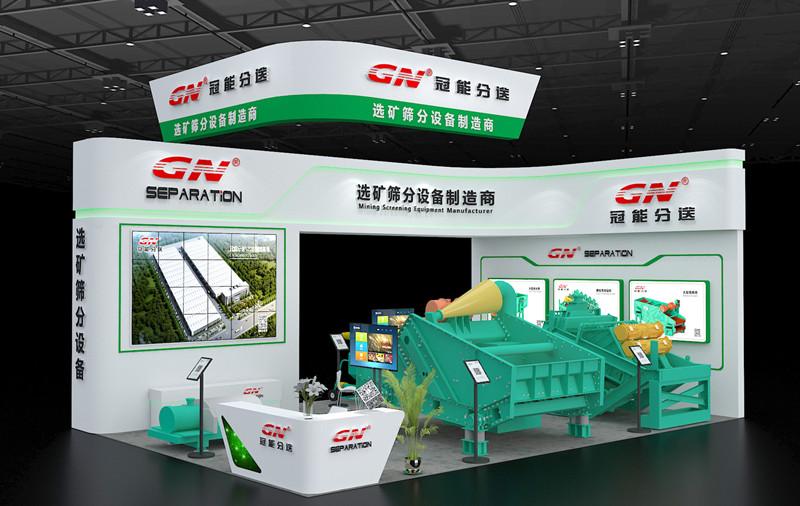

GN will be present at Bauma China in Shanghai from 26th to 29th November 2024 in Hall E6, Booth 350, with 70 square metres of exhibition space. We invite you to visit our booth and experience our innovative products and solutions.

Exhibiting Equipment

At the exhibition, we will focus on the following equipment:

High-frequency Stack vibrating screen - 2-Deck: with its efficient screening performance and excellent durability, this screening equipment is suitable for many industries such as mining, construction and recycling. It can effectively improve material separation efficiency and reduce energy consumption.

TBM mud processing system GNTBM-260B: Designed for shield construction, it has efficient mud cleaning and treatment capacity to ensure smooth construction process, reduce environmental pollution and enhance work safety.

Decanter centrifuge: This model of decanter centrifuge is known for its excellent solid-liquid separation performance and is widely used in the fields of chemical industry, foodstuffs and pharmaceuticals. Its stable operation and efficient separation capacity can significantly improve production efficiency and reduce operating costs.

Solid vacuum pumps: designed for handling various solid and liquid materials, with efficient pumping capacity and reliable performance, they are suitable for industries such as sewage treatment and mining.

Product Advantages

High efficiency and energy saving: our equipment is designed to focus on energy saving, which can effectively reduce energy consumption and improve economic efficiency.

Easy to operate: the equipment adopts user-friendly design, which is easy to operate and maintain and reduces the labour intensity of workers.

Environmental protection and safety: all products comply with environmental standards to ensure safety during construction and production.

We look forward to meeting you at Bauma to share more about Crown Energy Distribution's innovative technologies and solutions to help make your project a success!

- Details

-

Published: 10 November 2024

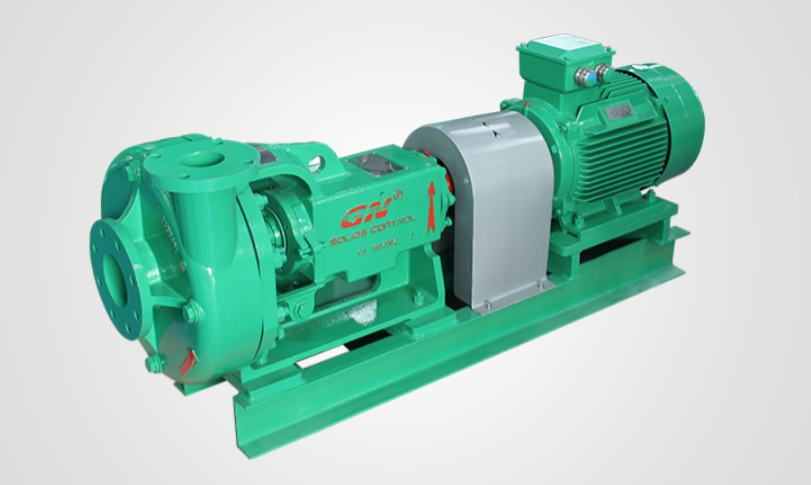

At GN Separation, we are committed to delivering reliable, high-performance solutions for a variety of industrial needs. Our GNSB Series Centrifugal Mud Pump is specifically designed to handle tough applications, from slurry and wastewater transfer to environmental and mining industry needs. Built for efficiency, durability, and ease of maintenance, this pump is an optimal choice for industries requiring high-volume, high-temperature slurry handling.

- Details

-

Published: 08 November 2024

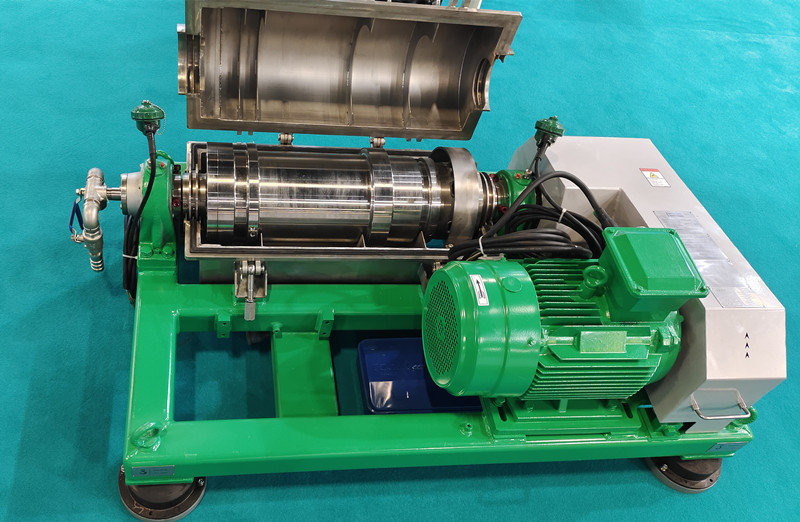

In industries where precise separation is critical, GN Separation’s High Speed Tubular Centrifuge offers a highly efficient solution. Also known as the Tubular Bowl Separator, this centrifuge is designed for fine separation tasks in the pharmaceutical, food, chemical, and biological product sectors, as well as in the fermentation, beverage, and blood product industries. Its high-speed capability is ideal for managing suspensions with low concentrations, fine particles, and small density differences, making it highly effective for both solid-liquid and liquid-liquid-solid separations.

Working Principle of GN High Speed Tubular Centrifuge

The High Speed Tubular Centrifuge separates materials by spinning them at high speeds, leveraging the differences in density among phases. Here’s an overview of the centrifuge’s operation for GN's two primary models:

GNGQ Model (Clarification Type)

The GQ type model is specialized for solid-liquid separation in suspensions where solids are present in low concentrations and have minor density differences from the liquid. Here’s how it works:

- The centrifuge reaches optimal working speed, and the suspension is fed continuously from the bottom.

- Under centrifugal force, the less dense liquid spirals up to discharge from the clear liquid outlet, while the denser solid particles settle in the bowl.

- After separation, the centrifuge is turned off to allow manual rotor removal for solid waste collection.

GNGF Model (Separation Type)

The GF type model excels in liquid-liquid-solid separations, especially useful where two incompatible liquids with a small density difference need to be separated alongside solid particles.

- The centrifuge reaches high speed, and the mixed suspension is fed from the bottom.

- The liquid with a lower density exits from the light liquid outlet, while the denser liquid flows from the heavy liquid outlet.

- Solid particles settle in the bowl and are manually removed after each separation process by rotor disassembly.

Key Features of GN High Speed Tubular Centrifuge

GN’s tubular centrifuges are crafted for reliability, versatility, and user convenience. The following features enhance their efficiency:

- Material Quality: Stainless steel 304 wraps the enclosure, and 316L stainless steel contacts the suspension, ensuring durability and sanitary compliance.

- Accessible Design: The square enclosure with a door-opening design allows easy assembly and disassembly, reducing labor intensity and maintaining high separation efficiency.

- Advanced Control Options: With optional VFD (variable frequency drive) control, speed adjustments become easy, reducing start-up currents and extending equipment life. Optional PLC and touch screens allow operators to monitor speed and temperature.

- Customization for Industry Needs: Models are available with explosion-proof configurations, cooling coils, and a mobile integrated base to fit various operational environments.

GN Tubular Centrifuge Models and Specifications

GN Separation offers a range of tubular centrifuge models, tailored to meet different capacity and performance requirements:

| Model | G-Force (G) | Bowl Diameter (mm) | Bowl Length (mm) | Volume (L) | Speed (rpm) | Flow Capacity (m³/h) | Motor Power (kW) | Dimensions (mm) |

|---|---|---|---|---|---|---|---|---|

| GNGQ076 | 17,000 | 76 | 430 | 2 | 20,000 | 0.6 | 1.5 | 650 x 380 x 1150 |

| GNGQ105 | 15,000 | 105 | 740 | 6 | 16,000 | 1.2 | 3 | 800 x 450 x 1620 |

| GNGQ142G | 15,760 | 142 | 820 | 10 | 14,000 | 1.5 | 3 | 910 x 620 x 1770 |

Note: Specifications are for reference. Models with "G" indicate a square box design.

Why Choose GN’s High Speed Tubular Centrifuge?

GN Separation’s High Speed Tubular Centrifuge provides a high-performance solution that combines durability, precise control, and operational flexibility. With advanced features tailored for diverse separation needs, GN Separation ensures that businesses can achieve high-quality results with efficient, reliable equipment.

For more information on GN Separation’s high-speed tubular centrifuge and how it can benefit your process, reach out to our team. GN Separation is committed to delivering advanced separation solutions, ready to support your industry needs with top-tier equipment and service.

- Details

-

Published: 01 November 2024

We are pleased to announce that Crown Energy Distribution will be participating in the International Mining and Resources Conference (IMARC), which will be held from 29-31 October 2024 at the International Convention and Exhibition Centre (ICC Sydney). The conference will bring together global mining leaders to discuss industry trends, investment opportunities and sustainable development.

Event Name: IMARC International Mining and Recourses Conference & Expo

Date: 29~31 October, 2024

Web:https://imarcglobal.com/

GN booth:Sydney International Convention and Exhibition Centre ICC Sydney

GN Booth S27

Visit us at our booth S27 to learn how our innovative solutions are driving efficient mining and environmental sustainability. We look forward to sharing our expertise with you and discussing future partnership opportunities.

GN will show the following equipment

GNLW224FT decanter centrifuge, With its compact design and efficient separation performance, the GNLW224 microcentrifuge is suitable for a wide range of laboratory and small-scale production applications. Its intelligent control system ensures easy and precise operation, making it ideal, especially in areas where efficient separations are required.

GN Stack Vibrating Screen is mainly suitable for wet screening, classification and dehydration treatment of fine-grained materials in mineral processing, coal preparation and other industries. It can be set to 2 to 5 layers according to on-site requirements. GN Stack Vibrating Screen is a self-developed product of GN company. It is designed and driven by a single vibration source (dual vibration motor) by using the principle of two-degree-of-freedom resonance to realize linear vibration of the whole machine. GN Stack Vibrating Screen has unique vibration mode, energy saving, high screening efficiency, large processing capacity, advanced technology, simple structure, stable and reliable operation, and is currently one of the most advanced equipment in the field of fine-grained material screening.

For more information, please visit the conference website at IMARC 2024 and we look forward to seeing you in Sydney!

- Details

-

Published: 30 October 2024

The GN Screw Press Sludge Dewatering Machine is a modern, environmentally friendly solution designed for effective sludge management across diverse industries. This advanced dewatering equipment operates on the principle of screw extrusion, using powerful compression forces generated by variances in screw diameter, pitch, and the narrow gap between the floating and fixed rings. This robust design enables precise solid-liquid separation, making it a sustainable, cost-effective choice for sludge dewatering.

- Details

-

Published: 28 October 2024

Sludge vacuum pump is a high load strong suction pneumatic vacuum transfer pump, also called solid vacuum pump. The vacuum is up to 25 inches of mercury (vacuum 85Kpa) and the head of the discharged water is up to 80 metres. Its unique structural design enables it to operate in particularly difficult environments with low maintenance, and it can transport materials with more than 80% solids and high specific gravity materials at high speed. It is characterised by a high efficiency venturi that generates a vacuum of up to 25 inches HG (mercury column) under strong air flow to pump the material, which is then conveyed under positive pressure with virtually no wear parts. Commonly used in the petroleum industry for drilling cuttings conveying, oily sludge conveying, tank cleaning operations, waste pumping over long distances, and mineral and waste conveying. In addition, it is also widely used in the chemical, mining and industrial fields for solid conveying, solid-liquid mixture conveying, and vacuum extraction.

Features of GN Solid Vacuum Pumps:

High Efficiency: GN solid vacuum pumps are designed to achieve low pressures quickly, making them ideal for applications requiring fast evacuation.

Robust Construction: Many GN pumps are built with durable materials to withstand harsh operating conditions and ensure longevity.

Low Maintenance: These pumps often require less maintenance compared to other types, reducing downtime and operational costs.

Versatile Applications: They can be used in industries such as pharmaceuticals, food processing, and electronics manufacturing.

Energy Efficient: GN pumps are designed to minimize energy consumption while maximizing performance.

Pls feel free to contact us if you have any further question.

- Details

-

Published: 27 October 2024