GN Separation is proud to announce the successful delivery of its advanced GNLWS364 3 Phase Decanter Centrifuge to a domestic environmental protection company in China. This marks a significant step forward in the country's efforts to improve waste management and oil-water separation processes.

- Details

-

Published: 06 September 2024

GN solid vacuum pump is a high-performance and compact device that can generate a vacuum degree of up to 25 inches of mercury. The suction generated by vacuum allows the garnet powder to be effectively sucked into the equipment, and then discharged and transported to the designated location through positive pressure.

Sludge vacuum pump, also known as solids vacuum pump or solids transfer pump, is a high load and powerful suction pneumatic vacuum pump. It is a vacuum pump that forms vacuum through gas movement for suction, and then converts it into pressure for material discharge. It can pump solid, powder, liquid and solid-liquid mixtures and many other different materials. There are no rotating parts in its cavity, which enables it to work in the most difficult environment, and it can transport more than 80% of the solid phase at high speed.

The characteristic of this device is its completely pneumatic operation mode, 100% air driving, which does not require electric power connection, so it can be safely used in areas with strict explosion-proof requirements. In addition, its compact structure and equipped wheels allow operators to flexibly move and layout equipment on site, greatly improving the convenience and practicality of the equipment.

Benefits

Efficiency: Quickly removes large volumes of sludge, saving time and labor.

Reduced Environmental Impact: Helps in effective waste management and cleanup.

Improved Safety: Minimizes the risk of spills and accidents by safely containing and removing hazardous materials.

For more informaiton, pls feel free to conatct GN.

- Details

-

Published: 01 September 2024

Recently, GN Segregation has successfully completed the assembly of two GNLW224 decanter centrifuges.

The GNLW224 is a decanter-type centrifuge designed for separation and dewatering applications in the salt and chemical industries, particularly for overseas markets.

It features a high-speed rotating bowl and screw conveyor that work together to effectively separate solid particles from liquid. This allows for efficient dewatering and drying of salt and other chemical products.

The centrifuge is constructed with corrosion-resistant materials like stainless steel to withstand the harsh environments and chemicals often encountered in salt and chemical processing facilities.

Key specifications include a bowl diameter of 224 mm, a maximum bowl speed of 4,500 RPM, and a liquid discharge capacity up to 15 m3/h depending on the application.

Common applications include dewatering and drying of salt, potash, soda ash, gypsum, and other mineral slurries for overseas markets where these chemical products are processed and exported.

The compact, modular design and rugged construction make the GNLW224 well-suited for installation and operation in remote or challenging locations common in international salt and chemical production facilities.

For more inforation, pls feel free to contact GN.

- Details

-

Published: 25 August 2024

GN Separation is renowned for delivering high-performance separation equipment across various industries. One of the flagship products in our lineup, the GNLW224 Decanter Centrifuge, has recently been deployed for a specialized application in the overseas salt chemical industry, showcasing its versatility and efficiency.

- Details

-

Published: 23 August 2024

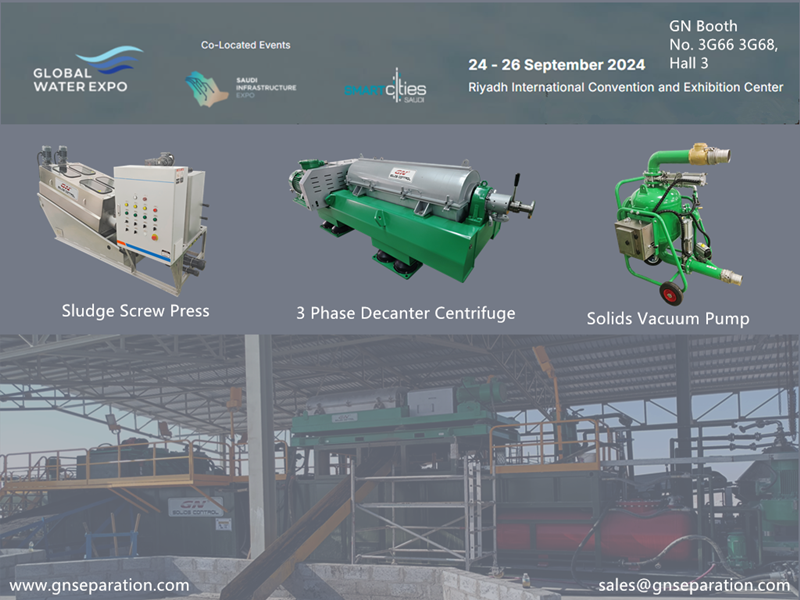

GN Separation is thrilled to announce its participation in the upcoming Global Water Expo, set to take place from September 24-26, 2024, at the Riyadh International Convention and Exhibition Center in Riyadh, Saudi Arabia.

- Details

-

Published: 19 August 2024

GN SEPARATION WILL ATTEND GLOBAL WATER EXPO THIS SEPTEMBER IN RIYADH,SAUDI APABIA

The Global Water Expo, to be held in the bustling metropolis of Riyadh in September this year, promises to be a key platform for showcasing the latest advances in water technology and treatment solutions.

Herewith pls find GN booth

Event Name: Global Water Expo

Event Date:24-26 September 2024

Expo Address:Riyadh International Convention and Exhibition Center

GN Bppth: 3G66-3G68, Hall3

Decanter centrifuge

Decanter centrifuge is a type of industrical centrifuge used for separating solid-liquid mixtures. It renowned for its high effciency, high automation, and minimal environmental impact.

Dewatering screw press

Dewatering screw press is a kind of fully automatic running machine with PLC in the control panel. It collects the sludge and flocculants to the premixing cabin. After the flocculation, the flocs will overflow into the dewatering assembly, after concentration stage and dewatering stage, the squeezed dry sludge cake will discharged out from the outlet.

Sludge vacuum pump

This pump operates on a simple yet ingenious principle, utilizing a helical rotor (screw) rotating within a stationary stator (housing) to create a continuous vacuum that draws in and transports fluids or slurries.

Oil sludge system

GN Oil Sludge System combines physical and chemical processes to effectively reduce the oil content of sludge into a more manageable and environmentally friendly form. The system promotes the recycling of valuable resources such as oil and water.

For more information on GN sludge transferring pumps, please no hesitate to contact.

- Details

-

Published: 15 August 2024