- Details

-

Published: 06 December 2024

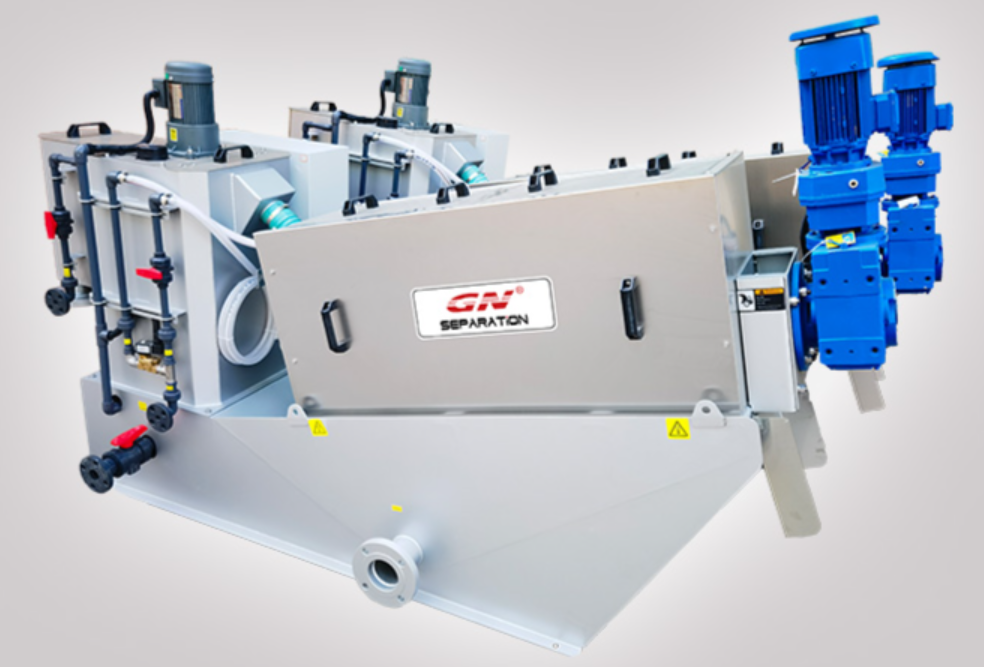

At GN Separation, we pride ourselves on providing innovative solutions for sludge dewatering across various industries. Among our diverse product offerings, the GN Screw Press Sludge Dewatering Machine stands out as an economic and environmentally friendly choice for solid-liquid separation.

What is the GN Screw Press Sludge Dewatering Machine?

The GN Screw Press Sludge Dewatering Machine is an advanced sludge extrusion system that utilizes the principle of screw extrusion. Its operation relies on:

- Variable Screw Diameter and Pitch: Generating strong squeezing force.

- Precision Gap Design: Featuring floating and fixed rings for efficient solid-liquid separation.

This design makes the GN Screw Press a reliable, clog-resistant solution for sludge dewatering.

Key Components of the GN Dewatering Screw Press

- Fully Automatic Control Cabinet: Ensures seamless operation.

- Flocculation Modulation Box: Automates the flocculation process for effective sludge conditioning.

- Sludge Thickening and Dewatering Device: Enables continuous thickening and squeezing.

- Liquid Collecting Tank: Gathers filtrate for return or discharge.

Applications Across Industries

The versatility of the GN Screw Press Dewatering Machine allows it to be employed in municipal sewage treatment and sectors like aquaculture, food processing, pharmaceuticals, chemical manufacturing, paper production, leather, starch, and oil industries.

Technical Excellence

The GN Screw Press caters to a broad range of sludge concentrations, from 2000 mg/L to 50000 mg/L, making it adaptable to various sludge types. Its robust design delivers capacities from 4 kg/h to 640 kg/h (dry sludge), with compact energy-efficient operation.

Performance Highlights (Sample Models):

| Model | Screw Diameter | Screw Power | Capacity (Dry Sludge) |

|---|---|---|---|

| GNDL131 | 130 mm | 0.2 kW | 4–14 kg/h |

| GNDL302 | 300 mm (x2) | 1.1 kW | 40–140 kg/h |

| GNDL404 | 400 mm (x4) | 6 kW | 266–640 kg/h |

Why Choose GN Screw Press Dewatering Machine?

- Wide Range Compatibility: Handles a variety of sludge, including oily sludge.

- Energy-Efficient Operation: Low energy consumption with compact design.

- Environmental Sustainability: No secondary pollution, aerobic dewatering to avoid phosphorus release.

- User-Friendly Automation: Fully automatic and continuous operation with minimal oversight.

- Durable and Clog-Free Design: Self-cleaning mechanism prevents blockage and ensures smooth operation.

How It Works

The GN Screw Press features distinct concentration and dewatering sections:

- Concentration Section: Gravity concentrates the sludge, prepping it for dewatering.

- Dewatering Section: As sludge moves forward, decreasing gaps and screw pitch increase pressure, reducing sludge volume and achieving high-efficiency dewatering.

A Compact Solution for Modern Challenges

GN Screw Press Dewatering Machines are the epitome of efficiency and sustainability. They combine low investment costs with high performance, delivering value to industries striving for cost-effective, eco-friendly solutions.

Whether you’re in municipal treatment, food processing, or heavy industry, the GN Screw Press is designed to meet your dewatering needs.

GN Separation looks forward to working with you to transform your sludge management challenges into sustainable solutions.

- Home

- /Efficient and Eco-Friendly Sludge Dewatering: GN Screw Press Dewatering Machine