- Details

-

Published: 26 December 2024

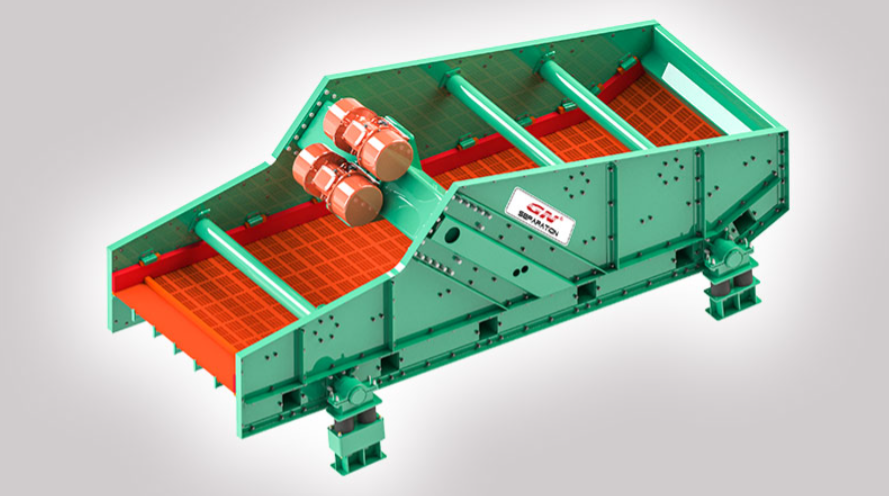

At GN Separation, we understand the importance of high efficiency and low energy consumption in the processing industries. One of our standout products, the GN Dewatering Vibrating Screen, plays a pivotal role in addressing challenges related to tailings treatment, dewatering, and material separation across various industries, including mining, coal, construction materials, metallurgy, and chemicals. With its robust design and versatile functionality, this linear motion dewatering screen is a highly effective solution for dewatering, desliming, demineralization, and dry discharge of mining tailings.

Key Features and Design Advantages

-

Advanced Design for Optimized Performance

The GN Dewatering Vibrating Screen is designed using cutting-edge technologies, such as finite element analysis and anti-fatigue analysis, ensuring that the structure of the screen is both robust and efficient. These design elements help reduce stress, minimize wear, and improve the overall operational lifespan of the equipment. -

High Efficiency and Low Energy Consumption

This equipment is specifically engineered for high dewatering and dry discharge capacities while maintaining low energy consumption. The high-performance vibration system ensures that materials are efficiently processed, even in demanding environments that are prone to corrosion and wear. -

Versatile and Customizable

The GN Dewatering Vibrating Screen is adaptable to various working conditions. It can be customized based on the specific requirements of the customer, such as the inclusion of different screen panel materials, processing capacity, and machine size. The installation angle can also be adjusted up to 4 degrees, allowing for flexibility depending on the material properties. -

Stable and Reliable Performance

Equipped with two vibrating motors, the GN Dewatering Vibrating Screen operates based on the principle of reverse self-synchronization. The screen body vibrates in a linear motion, enabling effective separation of solids and liquids, as well as coarse and fine particle separation. The continuous feeding of materials from the cyclone or feed tank ensures that the dewatering process is both efficient and consistent.

Technical Specifications

The GN Dewatering Vibrating Screen is available in a variety of models with different screen areas and processing capacities. Below are some key technical parameters:

| Model | Screen Area | Vibration Direction Angle | Vibration Frequency | Power | Double Amplitude | Screen Opening | Dry Material Discharge Capacity | Installation Inclination |

|---|---|---|---|---|---|---|---|---|

| GNLMZ1236 | 4.32 m² | 38~52 Degree | 16 Hz | 2*2.9 kW | 4~6 mm | 0.2-25 mm | 8~20 m³/h | ±4° |

| GNLMZ1536 | 5.4 m² | 38~52 Degree | 16 Hz | 2*2.9 kW | 4~6 mm | 0.2-25 mm | 12~25 m³/h | ±4° |

| GNLMZ1836 | 6.48 m² | 38~52 Degree | 16 Hz | 2*4.5 kW | 4~6 mm | 0.2-25 mm | 24~32 m³/h | ±4° |

| GNLMZ1848 | 8.64 m² | 38~52 Degree | 16 Hz | 2*5 kW | 4~6 mm | 0.2-25 mm | 25~35 m³/h | ±4° |

| GNLMZ2448 | 11.52 m² | 38~52 Degree | 16 Hz | 2*7 kW | 4~6 mm | 0.2-25 mm | 30~45 m³/h | ±4° |

Note: The above parameters are for reference only and can be adjusted according to the customer’s specific needs. The final quotation and technical agreement will be based on the exact requirements.

Key Benefits

-

Customization and Flexibility

The modular design allows for easy modification of the screen panel positions, enhancing the screen panel utilization and reducing spare parts inventory. Additionally, the polyurethane screen panels provide excellent wear resistance and elasticity, addressing common challenges such as screen blockage and enhancing the lifespan of the equipment. -

Robust Construction for Durability

GN’s dewatering screens feature rubber damping springs, providing a smooth and quiet operation while reducing vibration. The frame is constructed from high-impact resistant steel plates, ensuring that the machine is durable enough to handle tough working conditions. -

Corrosion and Wear Resistance

The screen surfaces and other parts exposed to fluid or abrasive materials are treated with polyurea coating, making them corrosion-resistant, wear-resistant, and highly durable. This treatment helps protect the machine from wear and tear, extending its service life and reducing maintenance costs. -

Optimized for Energy Efficiency

The machine’s vibration force is carefully calculated to balance energy consumption and performance. The resulting linear motion efficiently drives the dewatering process, while minimizing power usage, making it a cost-effective solution for long-term operations.

Applications Across Multiple Industries

GN Dewatering Vibrating Screens are highly effective in processing mining tailings and other industrial materials. They are commonly used in the following industries:

- Mining: For dewatering and desliming of mining tailings and sludge.

- Coal Industry: For effective separation and dewatering of coal slurry.

- Construction Material Industry: For separating and dewatering construction waste.

- Metallurgy Industry: For separating fine and coarse materials in mineral processing.

- Chemical Industry: For separating chemical materials and by-products.

Conclusion

The GN Dewatering Vibrating Screen is an efficient, reliable, and customizable solution for various industrial applications. Its advanced design, high processing capacity, and excellent durability make it an ideal choice for handling mining tailings, dewatering, and material separation. With a focus on energy efficiency and operational reliability, this equipment is well-suited to meet the demanding needs of industries requiring effective solid-liquid separation.

For more information or to get a customized quote, GN Separation looks forward to working with you. Contact us today to learn more about how we can help you optimize your operations with our high-performance dewatering equipment.