- Details

-

Published: 20 December 2024

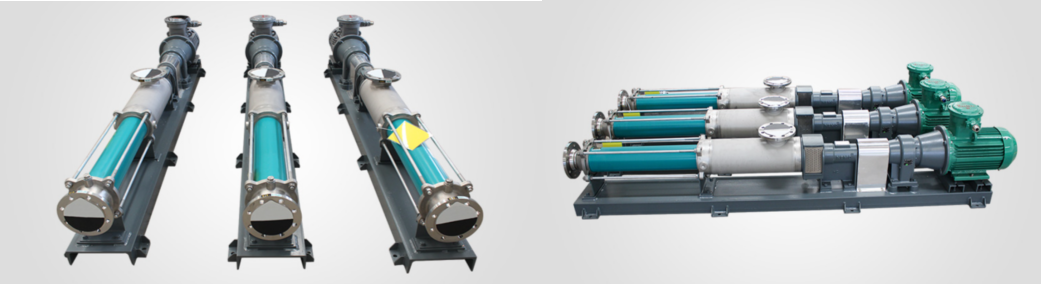

When it comes to precision pumping solutions, GN Separation is proud to introduce the GNG Series Progressive Cavity Pump, also referred to as a single screw pump. This cutting-edge pump is designed to meet the demanding needs of various industries, providing a combination of efficiency, durability, and reliability.

Innovative Design

The GNG Series Progressive Cavity Pump operates on a simple yet highly effective principle. It features a helical rotor turning inside a helical stator. As the rotor turns, a honeycomb-shaped cavity progresses spirally along the pump’s axis without altering its shape or volume. This unique mechanism ensures that materials are transferred from the intake to the discharge smoothly and without degradation. Such characteristics make the GNG Series pump an ideal choice for feeding decanter centrifuges.

Robust Construction and Performance

The GNG Series Progressive Cavity Pump is designed to handle a maximum load of 6 bar pressure, ensuring superior performance in the toughest conditions. The pump body and transmission parts are engineered for strength, durability, and safety, making it suitable for long-term, stable, and unmanned operations. Its flow capacity and head are perfectly tailored for sludge transportation and dosing applications, offering exceptional reliability.

Key Specifications

Below is a summary of the GNG Series Progressive Cavity Pump specifications:

| Model | Flow (m³/h) | Pressure (MPa) | Motor (kW) | Max Speed (RPM) | Inlet (Inch) | Outlet (Inch) | Weight (Kg) | Dimensions (L×W×H, mm) |

|---|---|---|---|---|---|---|---|---|

| GNG10-040C | 10 (44 GPM) | 0.3 | 4 | 244 | 3 | 3 | 245 | 2245×320×550 |

| GNG20-055C | 20 (88 GPM) | 5.5 | 210 | 3 | 3 | 323 | 2450×340×562 | |

| GNG30-075C | 30 (132 GPM) | 7.5 | 258 | 4 | 4 | 386 | 2761×370×600 | |

| GNG40-110C | 40 (176 GPM) | 11 | 252 | 5 | 5 | 454 | 3270×370×665 | |

| GNG50-110C | 50 (220 GPM) | 11 | 273 | 5 | 5 | 608 | 3790×400×782 | |

| GNG60-150C | 60 (264 GPM) | 15 | 225 | 5 | 5 | 649 | 3322×550×740 | |

| GNG70-220C | 70 (308 GPM) | 22 | 230 | 6 | 6 | 875 | 3740×420×785 | |

| GNG80-220C | 80 (352 GPM) | 22 | 283 | 6 | 6 | 875 | 3740×420×785 | |

| GNG90-220C | 90 (396 GPM) | 22 | 205 | 6 | 6 | 875 | 3740×420×785 |

Note: Specifications and parameters are for reference only.

Unique Features

-

Enhanced Stator Design:

-

The pump’s stator rubber is firmly bonded with the outer casing, eliminating seams, pores, or cracks on the working surface.

-

The stator is constructed from SBBPF or other high-grade materials, ensuring a design life of no less than 10,000 hours under specified conditions.

-

The stator’s feed end is funnel-shaped, ensuring full material flow.

-

-

Customizable Rotor Options:

-

The rotor can be made from stainless steel or hard alloy with special anti-abrasion and corrosion-resistant treatments, depending on the material and application requirements.

-

-

Integrated Gear Reducer and Motor:

-

The compact gear reducer integrates seamlessly with the motor.

-

The motor is compatible with 380V/460V or any customized power supply, with support for a 10-60Hz frequency range.

-

Applications Across Industries

The versatility of the GNG Series Progressive Cavity Pump makes it an excellent choice for a wide range of industries, including:

-

Chemical Industry: Ideal for handling polymers, sizing agents, resins, hardeners, acids, alkalines, oils, and water-based paints.

-

Mining Industry: Suitable for slurries, explosive preparation, coloring agents, and grinding additives.

-

Paper Industry: Efficiently pumps coating colors, dyes, starch, kaolin, talc, bentonite, calcium carbonate, and titanium dioxide.

-

Meat Industry: Handles pet food, fatty products, grease, tallow, lard, colza, and palm oils.

-

Sugar Industry: Processes molasses, glucose, syrups, starch, honey, and liquor.

-

Beverage Industry: Transfers juices, wine-making products, ingredients, additives, beer, and syrups.

Conclusion

With its robust design, reliable performance, and diverse application capabilities, GN Separation’s GNG Series Progressive Cavity Pump stands as a trusted solution for challenging pumping needs. Whether it’s sludge transportation, dosing, or handling sensitive materials, this pump delivers unmatched efficiency and durability.

Contact GN Separation today to learn how the GNG Series Progressive Cavity Pump can elevate your operations!