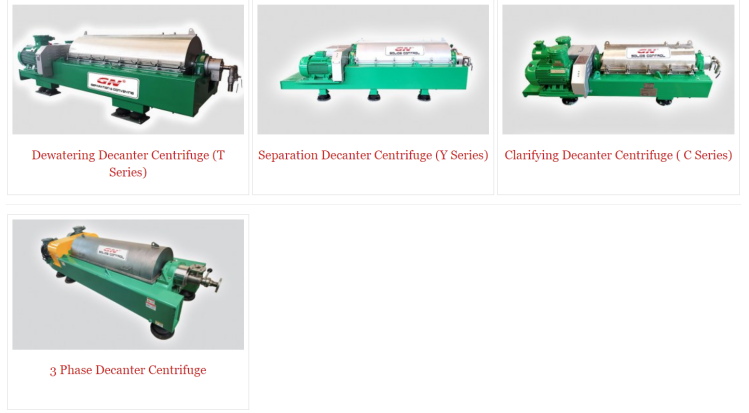

Introduction: Decanter centrifuges are essential equipment in various industries for separating solid-phase materials from liquid-phase materials. GN Separation offers a range of decanter centrifuges tailored to different separation needs. In this blog post, we'll delve into the features and applications of GN Separation's decanter centrifuge series.

- Details

-

Published: 08 March 2024

Nowsdays GN separation has invested in advance in its inventory to ensure that prompt delivery for some emergency order, following this situation, it also show us the productive ability of GN separation.

The solid vacuum pump of GN separation,it's 100% air driving pneumatic devicem, it's capbale of manage a wide range of the material, including liquid, solid and power. We have 3 different models, respectively GNSP-10B, GNSP-20B and GNSP-40B, due to the discrepany of the handping capacity, you can choose which handling capacity will meet your requirements.

It is worth mentioning that GN solids vacuum pump has passed EU CE and ATEX certification, fully meeting the strict standards of the European market. Especially for the GNSP10B and GNSP20B models, the equipment is equipped with wheels at the bottom, allowing operators to move and layout flexibly on site.

GN will continue to drive development through innovation, providing more effcient and safe material transportation solutions for global custoners, If yo have have further question, plesae feel free to connect to GN separation for any time.

- Details

-

Published: 08 March 2024

GN separation will attend the ASIA WATER 2024 EXHIBITION IN APRIL HELD IN MAYLAYSIA at the Kuala Lumpur Convention Centre on April 23-15th. Welcome to visit our booth for business/technical communicating. Herewith pls find our booth details as below

Expo. Name: ASIA WATER 2024

ADD: KUALA LUMPUR CONVENTION CENTRE

GN BOOTH NO: HALL6. B602

EXPO TIME: APRIAL23-25TH.2024

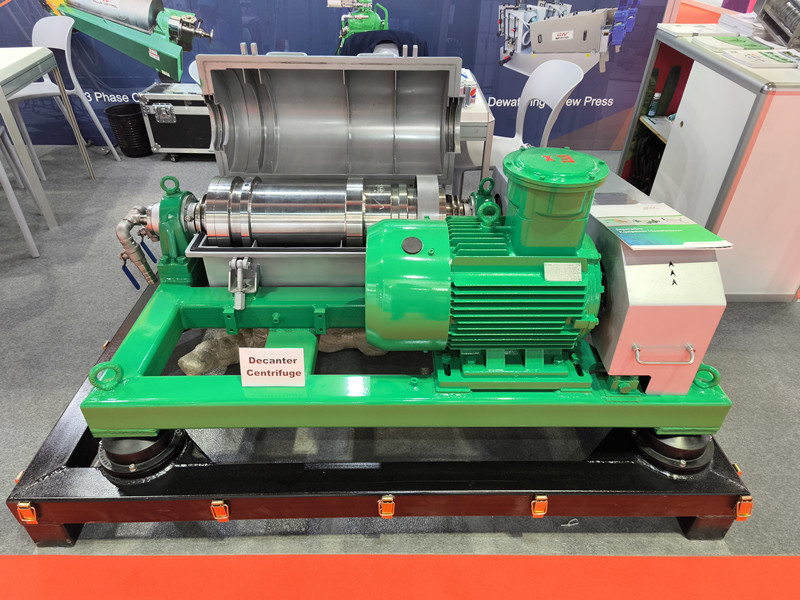

Our decanter centrifuge, solids vacuump pump and sludge dewatering screw press will be show at our booth.

1. Dewatering decanter centrifuge, A solid-liquid two-phase decanter centrifuge, also known as a decanter or a decanter centrifuge, is a type of industrial separation equipment used for separating solid particles from a liquid mixture. It operates based on the principle of sedimentation and centrifugal force.

2. GN solid vauum pump, A sludge vacuum pump operates by creating a vacuum or suction that effectively pulls the sludge into the pump and transfers it to a desired location for further processing, disposal, or treatment. These pumps are often equipped with robust construction and specialized features to handle the demanding nature of sludge.

3.GN dewater screw press is with com[act structure, low noise, and low energy consumption, making it widely applicable in municipal wastewater treatment project as well as in sludge treatment for various industries such as aquaculture, food, pharmaceutical, chemical ,papaermaking and leather.

For more details, please feel free to contact GN.

- Details

-

Published: 03 March 2024

GN Separation: Delivering Excellence with 2 Sets GNLW224 Decanter Centrifuge for Australian Customer

In the realm of centrifugal separation technology, precision, reliability, and adaptability are paramount. When it comes to meeting these demands, our 2 Sets GNLW224 Decanter Centrifuge from GN separation stands out as an exemplary solution. Recently, we had the privilege of supplying these centrifuges to our esteemed customer in Australia, tailored precisely to their unique requirements.

- Details

-

Published: 28 February 2024

We are pleased to confirm the provision of two sets of GNLW224 Decanter Centrifuge to our valued Australian customer. In accordance with the customer's specifications, we have meticulously selected ABB brand motors to power these centrifuges. ABB motors are recognized for their superior performance, reliability, and energy efficiency, making them an ideal choice for industrial applications.

Moreover, these centrifuges are equipped with high-quality bearing temperature sensors and vibration sensors, meticulously chosen to ensure optimal performance and early detection of any potential issues. These sensors are vital for proactive maintenance and minimizing the risk of unexpected downtime, aligning with our commitment to delivering reliable and efficient solutions to our customers.

Furthermore, to adhere to the customer's requirements, the GNLW224 Decanter Centrifuges comply with the IEC Ex explosion-proof standards. This ensures that the equipment is safe to operate in potentially hazardous or explosive environments, underscoring our dedication to prioritizing safety and reliability in all our offerings.

We are confident that these GNLW224 Decanter Centrifuges, outfitted with ABB motors, bearing temperature sensors, vibration sensors, and IEC Ex explosion-proof compliance, will meet and exceed our Australian customer's expectations, providing them with efficient, reliable, and safe solutions for their industrial needs.

For more information, please feel free to contact us.

- Details

-

Published: 25 February 2024

Recently, GN have completed the assembly of 2 sets GNLW224 decanter centrifuge, they will be arrange to send to the overseas customer nowadays.

The GNLW224 decanter centrifuge is a smallest moedel of solid liquid separation machine base on our decanter centrifuge.

We are pleased to provide two sets of GNLW224 Decanter Centrifuge that meet the specific requirements of our Australian customer. As per the customer's request, we have carefully selected ABB brand motors to power these centrifuges. These motors are renowned for their reliability, efficiency, and durability, making them an ideal choice for industrial applications.

In addition, the centrifuges are equipped with high-quality bearing temperature sensors and vibration sensors to ensure optimal performance and early detection of any potential issues. These sensors are essential for proactive maintenance and minimizing the risk of unexpected downtime.

Furthermore, in compliance with the customer's specifications, the GNLW224 Decanter Centrifuges are designed to meet the IEC Ex explosion-proof standards. This ensures that the equipment is safe to operate in potentially hazardous or explosive environments, providing peace of mind for our customer and aligning with their safety protocols.

We are committed to delivering top-quality products that not only meet but exceed our customer's expectations. These GNLW224 Decanter Centrifuges with ABB motors, bearing temperature sensors, vibration sensors, and IEC Ex explosion-proof compliance are a testament to that commitment. We are confident that they will serve our Australian customer's needs effectively and reliably.

For more details of our decanter centrifuge, please fell free to contact us.

- Details

-

Published: 25 February 2024