Decanter Centrifuge

Oilfield Decanter centrifuges manufacturer, drilling fluids decanter centrifuge,supply high speed drilling mud Decanter

centrifuge solids control, dewatering

GN Decanter Centrifuge is designed for the drilling mud solids control and oilfield waste management.GN VFD drive decanter

centrifuge with variable speed allows drilling contracor or mud service company to do the barite recovery, fine/ ultra fine

solids separation,dewatering centrifuge.GN have the decanter centrifuge from 9 inch bowl to 22 inch bowl available for

different applications.GN decanter centrifuge bowl length and diameter ration is over 3, this gives the best result for the

drilling fluids cleaning.

Remarks, Economic Configuration decanter centrifuge, and mini Centrifuge is in the bottom table.

High Configuration Decanter Centrifuge Features

•Patent Design with the highest configuration and best material for long and reliable service.

•Bowl Cylindrical and Conical section made from Duplex Stainless Steel 2304 by centrifugal casting.

•Other Parts of the bowl assembly material: stainless steel SS304.

•Screw protection: Tungsten Carbide Tiles for longer life and easier replacement.

•Screw flow distribution port and bowl solids discharge port protected by tungsten carbide alloy.

•Easily adjustable liquid discharge weir height for flexible application.

•Bowl assembly supported by tighten belt for protection of bearing in moving.

•Pressurized EX Proof VFD control cabinet with PLC controlled.

•Genuine SKF bearing for longer and reliable operation

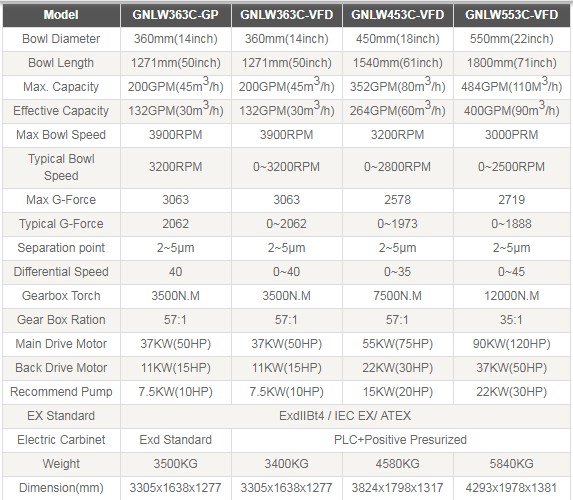

GN High Configuration Decanter Centrifuge Parameter

•Patent Design with the economic configuration

•Bowl Cylindrical and Conical section made from Duplex Stainless Steel

•SS304 by centrifugal casting

•Other Parts of the bowl assembly material: stainless steel SS304.

•Screw protection: Ceramic Tiles for longer life and easier replacement.

•Screw flow distribution port and bowl solids discharge port protected by tungsten carbide alloy.

•Easily adjustable liquid discharge weir height for flexible application.

•Bowl assembly supported by tighten belt for protection of bearing inmoving.

•Pressurized EX Proof VFD control cabinet.

•Genuine NSK/FAG bearing

- Details

-

Published: 26 December 2018

Large Bowl 30 inch GNLW764A Decanter Centrifuge for Mining Industry to Australia

Dec 20 2018

This week, GN arranged the shipment of two sets large bowl deca nter centrifuge to Australia for coal mining slurry dewatering process.

nter centrifuge to Australia for coal mining slurry dewatering process.

The model of the large bowl decanter centrifuge is GNLW764 that is the largest centrifuge GN can make at this time. For the coal slurry dewatering project, always a large flow capacity is required. That is why the client selected GN largest decanter centrifuge.

Features of GN Large Bowl Decanter Centrifuge GNLW764A

1. The rotating bowl is made from duplex stainless steel 2304 with centrifugal casting processing for better balance performance.

2. Screw conveyor is also rom stainless steel and the blade is protected with tungsten carbide for long working life.

3. To protect the motor of the large bowl decanter centrifuge. GN equips the VFD control panel for the operation of the centrifuge. So that the motor can be started to run at a low speed to prevent the over high electric current to burn the motor. In the meanwhile, a VFD control panel will let the operator to run the decanter centrifuge with different speed for various process purposes.

4. The lubrication system is using oil pump to feed lubricants to both of the bearing seats. The plate type heating exchanging system can effectively cool down the lubrication oil so that to get a better cooling performance and the temperature sensor installed on the bearing seat will send signal to the PLC to trip off the centrifuge in case of over high temperature.

GN decanter centrifuge is mostly used in drilling mud solids control. However, now is applied in more and more other industries like mining slurry dewatering, waste water treatment and oily sludge treatment. For more information on GN big bowl decanter centrifuge, please contact us freely.

- Details

-

Published: 20 December 2018

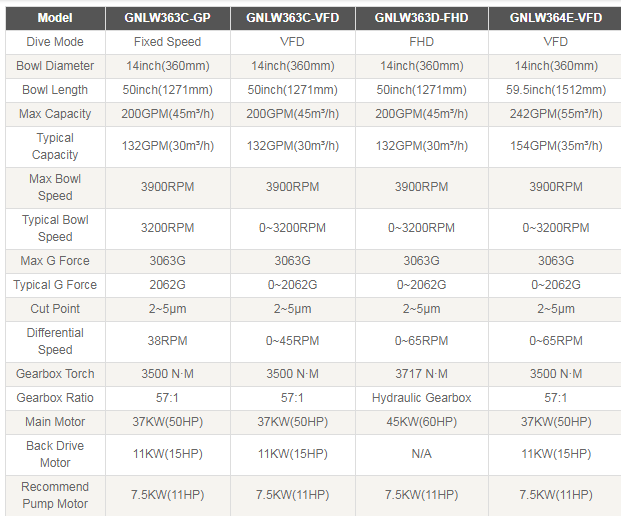

14 Inch decanter centrifuge

The GN 14 inch (360mm) diameter bowl decanter centrifuge which has a length over diameter ratio of 3.5:1 with high speed up to 4000 RPM. The centrifugally casted duplex stainless steel bowl and the tungsten carbide hardened tiles on the solids conveyor maximize the GNLW363 centrifuges operational service life between overhauls. The GNLW363 features replaceable ceramic/tungsten carbide inserts at the feed distribution and solids discharge zones. The unit also has Tungsten Carbide plows to continuously clear the solids discharge area. All bearings fitted to the GNLW363 centrifuge are SKF premium brand bearings for extended service life and reliable operation

The GN 14 inch (360mm) diameter bowl decanter centrifuge  which has a length over diameter ratio of 3.5:1 with high speed up to 4000 RPM. The centrifugally casted duplex stainless steel bowl and the tungsten carbide hardened tiles on the solids conveyor maximize the GNLW363 centrifuges operational service life between overhauls. The GNLW363 features replaceable ceramic/tungsten carbide inserts at the feed distribution and solids discharge zones. The unit also has Tungsten Carbide plows to continuously clear the solids discharge area. All bearings fitted to the GNLW363 centrifuge are SKF premium brand bearings for extended service life and reliable operation

which has a length over diameter ratio of 3.5:1 with high speed up to 4000 RPM. The centrifugally casted duplex stainless steel bowl and the tungsten carbide hardened tiles on the solids conveyor maximize the GNLW363 centrifuges operational service life between overhauls. The GNLW363 features replaceable ceramic/tungsten carbide inserts at the feed distribution and solids discharge zones. The unit also has Tungsten Carbide plows to continuously clear the solids discharge area. All bearings fitted to the GNLW363 centrifuge are SKF premium brand bearings for extended service life and reliable operation

Popular Applications

Drilling Fluids Solids Control

Industry Waste Water Treatment.

Oil Sludge Treatment

Municipal Sewage Sludge in Purification Plants

Mining Industry Separation.

Dredging Slurry Separation

GN Solids Control focus on separation equipment manufacture.After research and development for over 10 years, GN Solids Control have become the leading brand for separation equipment. And GN is honored to be the National High Tech company, which means we pay 15% income tax instead of 25%, this will give benifit to our customer for buying cost effective product from GN

- Details

-

Published: 13 December 2018

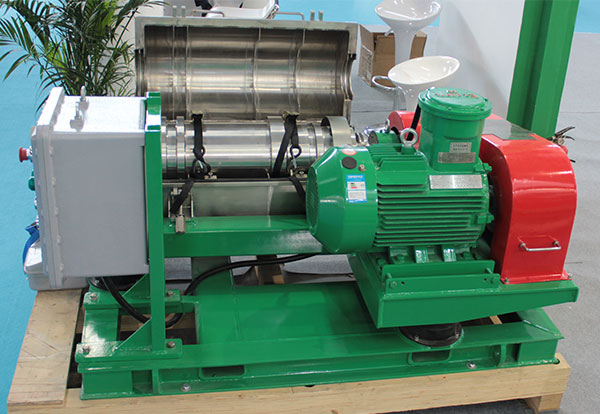

Shale Shakers and Decanter Centrifuges for Russia Drilling Rig

After a whole day packing and marking labels, GN just shipped out one batch shale shakers and decanter centrifuges to equip the oil well drilling rigs in Russia. Shale shaker and decanter centrifuge are two of the key equipment in drilling mud recycling system. The shale shaker separates the cuttings by using the wire mesh screen opening size to block the coarse cuttings, while the decanter centrifuge is separate ultrafine solids by using centrifugal force.

GN shale shaker could be used in drilling mudsolids control system as the primary shaker unit and also as the high G force drying shaker in waste cuttings management system.

Below features make GN shale shaker the reliable performance in using

1. Shaker vibrating deck is completely heat treatment for higher vibration G force

2. Shaker is installed with GN self-produced composite frameshaker screen with longer working time.

3. Patented rubber sealing installation method make the replacement of rubber strip much easier and better sealing performance.

GN decanter centrifuge could be used in drilling mud solids control system for fine solids separation like the suspending barite recovery and useless cuttings removing. In the waste cuttings management system, the high speed decanter centrifuge could be used to treat the effluence discharged from the cuttings dryer. Besides the petroleum industry, the decanter centrifuge is also widely used in mining and environmental protection industry.

The decanter centrifuge shipped to Russia in this order is the popular 14 inch model with designed maximum speed up to 3900RPM. It could be control as fixed speed or variable frequency.

Below features make GN decanter centrifuge excellent performance.

1. Bowl material is from duplex stainless steel 2305 with good machinability.

2. Centrifugal casting technology makes the bowl material distribution evenly for a good dynamic balance.

3. Tungsten material tile or bushing protection at abrasive part for longer working time and less maintenance.

4. PLC control panel is available, and the sensors could be put on the centrifuge unit to monitor the status of the machine.

For more information on GN Solids Control, please feel free to contact.

- Details

-

Published: 13 December 2018

9 Inch (220) Decanter Centrifuge – Baby Centrifuge

GN design and manufacturer different size of decanter centrifuges for industry separation. Solid bowl decanter centrifuges have been operating according to the same basic principle since 19th century.GN centrifuge production line is from 9 inch (220MM) bowl to 30 inch (760mm) bowl, with bowl length and diameter ration up to 4.2, and the adjustable G force is up to 3000G to meet different industry separation applications

The 9 Inch Decanter Centrifuge is a baby centrifuge which is the world smallest industry decanter. The bowl of the centrifuge is 9 inch (220mm). As the compact design, it’s popular for client to use it in small capacity or limited space application for solids and liquid separation

The 9 Inch Decanter Centrifuge is a baby centrifuge which is the world smallest industry decanter.

The bowl of the centrifuge is 9 inch (220mm). As the compact design, it’s popular for client to use it in small capacity or limited space application for solids and liquid separation. It is also considered to be the best choice for experiment testing with decanter centrifuge.GN 9 inch decanter centrifuge is optional in three types includes: fixed gear box drive, fully hydraulic drive, and variable frequency drive.

Popular Applications

Industry Waste Water Treatment.

Diamond Core Drilling Fluids Treatment.

- Details

-

Published: 30 November 2018

Drilling fluid, commonly known as mud, is translated into drilling mud in English. It is recognized as the blood of oil field drilling and plays a very important role in drilling operations. Therefore, the drilling fluid is very demanding, mainly in four aspects:

1. Requirements for drilling cycle

Drilling fluid requirements for drilling fluid are low pump pressure (low viscosity), strong sand carrying capacity (high dynamic shear force), low starting pump pressure (low static shear force), good lubrication performance, low friction and low wear (less solid particles) ).

2. To maintain the stability of the wellbore

The drilled formation should be balanced by the pressure column of the drilling fluid and the pressure of the formation. The density of the drilling fluid is stable. When drilling the oil and gas layer, the pressure column of the drilling fluid is used to balance the pressure of the oil and gas. The drilling fluid is required to overcome the performance of the unstable formation, such as the expansion of the wellbore caused by the swelling of the mudstone; the conglomerate and the volcanic rock collide with the water, and the salt rock forms a cave with water, which requires different drilling fluids.

3. Require drilling fluid to protect oil and gas layers

After drilling the oil and gas layer, the drilling fluid is in contact with the oil and gas layer. In order to prevent the drilling fluid from damaging the oil and gas layer, the drilling fluid is required to have small water loss and thin mud cake. After the drilling fluid loses water, the solid pressure difference solid particles form mud on the well wall. The cake ring), the solid phase content is low, and the hydration of the filtrate is low (the chemical action of the filtrate after entering the formation and the liquid in the formation).

4. Protect the environment and ecology

Drilling fluids often contain crude oil, diesel oil and various oils and contain a large amount of chemical treatment agents. To prevent the environmental and ecological effects of drilling fluids, it is required to use harmless and non-toxic drilling fluids.

Mud has many functions, mainly to carry cuttings from the bottom of the well to the ground. With the rapid advancement of oilfield science and technology, drilling fluids have evolved from just drilling drills to adapting to all aspects of drilling.

1. Clean the bottom of the well, suspend and carry debris, and keep the wellbore clean.

2. Balance formation pressure, stabilize wellbore, prevent well collapse, blowout, and lost circulation.

3. Pass water power to help the bit break the rock.

4. Passing power to the downhole power drill,

5. Cool the drill bit and the drill.

6. Drilling fluid is used for geological and gas logging.

7. Offshore oil drilling and completion projects, including geological, exploration, cementing, casing, logging, logging, etc., need to be completed by the cooperation of mud.

- Details

-

Published: 23 November 2018