GN Company supplied one unit of Solid Vacuum Pump for Hongkong client, for his construction project. It's a type of Pneumatic pump, which sucks solid/sludge/slurry with vacuum, based on the principle of Venture. The pump is 100% air operation, and generally the air is supplied by air compressor.

This Hongkong client purchased one unit of GNSP-40B, with capacity 40m3/hour, horizontal suction distance 100 meters, and discharge distance 1000 meters. And its vertical suction depth is 8m, while head/lift can reach about 80 meters.

GN Solid Vacuum Pump, also named Solid Transfer Pump, its main features & applications as follow,

100% Air Operation (we suggest clients to find air compressor from local market, and factories are always available with air source)

Safe in operation and different applications

NO internal workings/moving parts

Transferring high gravity/density sludge

Transferring solids, with content maximum up to 80%

Transferring slurry, water, etc

Attn., air demand ranges 4.3~17m3/hour for different models of pump.

GN Company already supplied this pump to UK, Russia, Norway, Greece, Middle East countries, Southeast Asia, India, Africa, etc.

Now GN Company Sales Managers have been working hard to develop the market and new clients in different countries, we are open to find Reliable Business Partners for developing local market together, but that completely depends on real marketing capabilities and orders the partners can bring to us in the first stage.

Welcome to contact GN Company about our pump working video and technical specifications.

- Details

-

Published: 05 January 2020

GN Separation and Conveying Company supplied one unit of Disc Separator for Phosphoric Acid Plant in Africa.

The Disc Separator, also named 3 Phase Separator, is used for Solid Liquid Liquid separation, such as Vegetable Oil, Animal Oil, Starch, Dairy, Beverage, Beer, Biological, Pharmaction, Chemical, Waste Cooking Oil, Biodiesel Oil, Mineral Oil, etc.

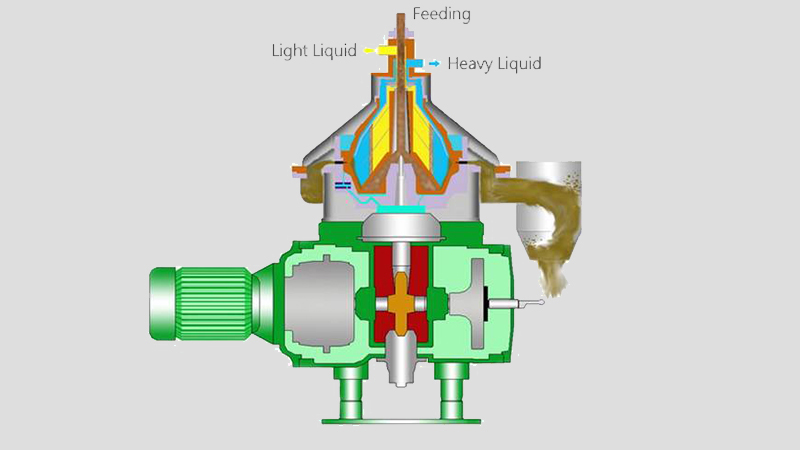

The Disc Separator's working principle as follow,

The material is feed into the heart parts of the machine, the inside of drum. Under the action of strong centrifugal force, the material passes through the separation interval of a group of disc bundles, with the neutral hole of the disc separator as the interface, the liquid with higher density (heavy phase) moves outward the neutral hole along the disc pieces, among which, the heavy residues accumulates in the sediment area, and the heavy phase flows to the large centripetal pump. The liquid with smaller specific gravity, light phase, moves along the disc wall toward the neutral hole and converges to the lower centripetal pump. At the same time, the light and heavy phases are respectively output by the lower centripetal pump and the upper centripetal pump, and the heavy slag is periodically discharged, so continuous production can be achieved.

GN Company now is capable to manufacture Disc Separator with capabilities ranging from 1m3/hour~25m3/hour, and automatic sludge discharging function and self-cleaning function. And its bowl diameter is from 440mm~800mm, slide piston is from 380mm~700mm, and maximum speed is from 4500RPM-7100RPM.

Attention, the solid content in the slurry feeding into Disc Separator shall be less than 3%, and solid size shall be less than 400um, in order to get the best performance.

GN Company also manufacture Decanter Centrifuge and Shale Shaker, which can be used to separate out coarse size solid more than 20um.

Welcome to contact GN Company sales managers for working videos and technical specifications.

- Details

-

Published: 28 December 2019

Norway client ordered one set of Sludge Solid Vacuum Pump from GN Company, for his ship repairing plant, and got great performance.

GN Company has 3 models of Vacuum Pump, with different capacities, 10, 20, 40m3/hour, and horizontal suction distance ranging from 50~100meters, while discharge distance ranging from 500~1000meters, and vertical suction distance 8meters, while head/lift distance can reach 80meters.

The Main Features of GN Sludge Solid Vacuum Pump as follow,

100% Air Operation

Safety in the industry

NO internal workings/moving parts

Fixed or Mobile/Moveable Unit

Generates 25''hg vacuum

Automatic Operation

Reverse Vacuum

GN Sludge/Solids Vacuum Pump Applications as follow,

Slurry, Sludge removal and transfer

Mud and tailings transfer

Pit and Sump cleaning

Oil sludge, tank bottoms residual removal and transfer

Barge tank and silo transfer of material

Sand; course, fine, conventioal and frac sand

Diatomaceous earth

Hazardous waste removal with close circuit transfer

Animal waste

Transfers virtually any material

GN Company already supplied equipment to about 76 countries, including Canada, USA, Australia, UK, Netherlands, Greece, India, Middle East Countries, Southeast Countries, African Countries, and 70% sales amount are from International market.

GN Company has head office & three factories in China, and one office in Russia, and one office & warehouse in USA.

GN factories are only one hour from the Beijing International Airport by car, welcome to contact GN Sales Managers and visit factories.

- Details

-

Published: 22 December 2019

There is one client from Norway, he purchased Sludge Solid Vacuum Pump from GN Company, used for his ship repairing plant, and got great performance.

GN Sludge/Solids Vacuum Pump Features as follow,

100% Air Operation

Safest in the industry

NO internal workings/moving parts

Fixed or mobile system

Horizontal Suction Distance 50~100meters, Discharge Distance 500~1000meters.

Vertical Suction Distance 8meters, Lift/head can reach 80meters.

GN Sludge/Solids Vacuum Pump Applications as follow,

Slurry, Sludge removal and transfer

Mud and tailings transfer

Pit and Sump cleaning

Oil sludge, tank bottoms residual removal and transfer

Barge tank and silo transfer of material

Sand; course, fine, conventional and frac sand

Diatomaceous earth

Hazardous waste removal with close circuit transfer

Animal waste

Transfers virtually any material

GN Company focus on manufacturing Separation & Conveying Equipment for 12 years, including Decanter Centrifuge, Disc Separator, Sludge Solid Vacuum Pump, Screw Conveyor, etc.

GN Company has two factories under operation, and builds a third one with more than 100,000 square meters totally, which would come into operation in the next year.

GN Company's 70% of sales amount is from International Market, including America, Canada, Russia, Australia, Middle East Countries, Southeast Asia, Africa, etc.

GN Company has two branch companies in Russia and USA, with equipment & spare parts stocking in warehouse in Houston for selling.

Welcome to visit GN Company, and contact GN sales managers for more Technical Speciation & Working Video.

- Details

-

Published: 15 December 2019

GN Company joined IFAT Exhibition in Mumbai, India on October 16~18th, and we showed our Decanter Centrifuge, Sludge Solid Vacuum Pump during the exhibition, and got great feedback. And there is One Indian Company placing one order of Sludge Solid Vacuum Pump, GNSP-20B, to GN Company, it is less than one month later after the exhibition. This client plans to purchase our pump for transferring some oily sludge in his job site.

GN Sludge Solid Vacuum Pump can be widely used for transferring Solid, Sand, Soil, Slurry, Water, etc. It has much more applications than common centrifugal pump, details as follow,

Slurry, Sludge removal and transferring

Mud and tailings transferring

Pit and Sump cleaning

Oil sludge, tank bottoms residual removal and transferring

Barge tank and silo transferring of material

Sand, course, fine, conventional and frac sand

Diatomaceous earth

Hazardous waste removal with close circuit transfer

Animal waste

Transfers virtually any material

This pump is 100% air operation, and no cost of electricity or diesel, only needs to be supplied with qualified air. Now there are 3 models of that pump, with different capacities, ranges from 10~40m3/hour.

The maximum horizontal discharge distance is 1000 meters, and suction distance is 100meters. And maximum vertical suction depth is 8meters, and lift/head can reach 80meters.

Welcome to contact GN Sales Managers for pump technical specifications and working videos.

And it is acceptable to do Trial Test with clients' sludge/material with our pump within GN factories.

- Details

-

Published: 08 December 2019

GN Oil Water Separator can be used to remove free non-emulsified oils, diesel, gasoline and fuels from waste stream by coalescing media. Because of its high capacity and easy operation, oil water separator is popular for primary Oil Water separation project, including groudwater remediation, vehicel wash racks, stormwater treatment, Oil Production and Spill Recovery, etc.

GN Company Oil Water Separator capacity ranges from 6m3/h to 262 m3/h, and the material can be stainless steel and carbon steel.

Working Procedure of GN Oil Water Separator

1) Oil Droplets Coalesce

Waste water feeding into oil water separator and flowing through a tightly stacked bundle of coalescing media. The coalescing media expands the surface area of the oil water separator giving the free oil more space on which to coalesce. As the oil droplets accumulate on the coalesce media and turned into larger droplets. Later on the larger drop flow up the surface of the media, detach and rise to the water surface. Because of the difference gravity of oil water and solids, so they can be separated.

2) Oil Decants to Oil reservoir

Surface oil decants by gravity into a segregated oil reservoir to be removed from the tank.

3) Solids Slide down to sludge chamber

Since the solids gravity is bigger than water, the solids will slide down the surface of the media into the sludge chamber at the bottom of the tank for removal when it’s necessary.

4) Clean water collection

After that, the oil free relatively clean water travels under an oil reservoir baffle, over an adjustable weir and into a clean water effluent chamber which will be discharged from this chamber by gravity.

Welcome to visit GN factories, and do trail test within our work plant.

- Details

-

Published: 30 September 2019