GN Solids Control focus on separation equipment manufacturer. After research and development for over 10 years, GN Solids Control has become the leading brand for separation equipment.And GN is honored to be the National High Tech Company, which means we pay 15% income tax instead of 25%, this will give benefit to our customer for buying cost effective product from GN.The decanter centrifuge is also our main product, with the reasonable price and good reputation in the centrifuge market of the wold

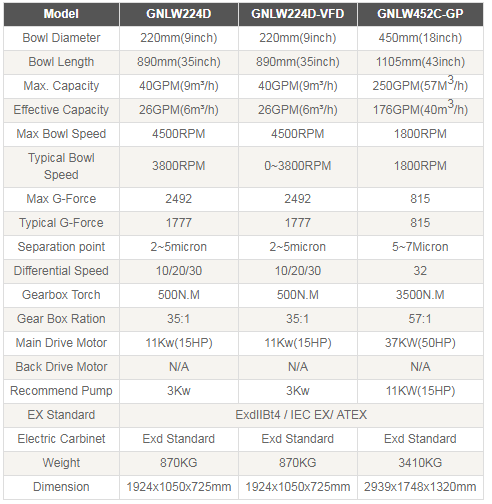

GN Decanter Centrifuge is designed for the drilling mud solids control and oilfield waste management.GN VFD drive decanter centrifuge with variable speed allows drilling contracor or mud service company to do the barite recovery, fine/ ultra fine solids separation,dewatering centrifuge.GN have the decanter centrifuge from 9 inch bowl to 22 inch bowl available for different applications.GN decanter centrifuge bowl length and diameter ration is over 3, this gives the best result for the drilling fluids cleaning.

Remarks, Economic Configuration decanter centrifuge, and mini Centrifuge is in the bottom table.

High Configuration Decanter Centrifuge Features

•Patent Design with the highest configuration and best material for long and reliable service.

•Bowl Cylindrical and Conical section made from Duplex Stainless Steel 2304 by centrifugal casting.

•Other Parts of the bowl assembly material: stainless steel SS304.

•Screw protection: Tungsten Carbide Tiles for longer life and easier replacement.

•Screw flow distribution port and bowl solids discharge port protected by tungsten carbide alloy.

•Easily adjustable liquid discharge weir height for flexible application.

•Bowl assembly supported by tighten belt for protection of bearing in moving.

•Pressurized EX Proof VFD control cabinet with PLC controlled.

•Genuine SKF bearing for longer and reliable operation

- Details

-

Published: 16 November 2018

Treatment of oil sludge

Patent name: treatment method of sludge

Technical field:

The invention relates to a method for treating oily sludge.

Background technique:

Sludge mainly refers to oily sludge formed by crude oil or other oils and mud due to various reasons, and oily sediment brought out by the system in normal production of oil fields. It is a kind of solid waste rich in mineral oil, mainly The ingredients are crude oil, mud and water. The solid particle size can range from less than a few microns to a few inches, most typically between 1 and 100 microns. The composition of the oil depends on the type of crude oil, the structure of the refinery and the operating conditions, and the composition of the sludge may change over time. Usually, the sludge contains a certain amount of crude oil (concentration mass 5% 80%), heavy metal ions (such as iron, copper, nickel, etc.) and inorganic salts (concentration mass 5% 20%) compounds. These sludges generally contain substances such as benzenes and phenols, which are accompanied by malodor and toxicity. If they are directly in contact with the natural environment, the soil will be poisoned, acidified or alkalized, resulting in changes in soil and soil structure, hindering plant root growth and It will cause greater pollution to water bodies and vegetation, and it also means waste of petroleum resources. According to the national list of hazardous wastes, sludge is classified as hazardous waste, and its long-term and potential environmental hazards are receiving great attention. Carrying out research on sludge management and prevention technology is an important task of the national environmental protection work. Therefore, how to make these oil-containing sludges harmless and resource-utilized is also an important environmental issue that needs to be solved in the face of the refining industry. At present, the technologies for treating oily sludge mainly include resource recovery, harmless treatment and comprehensive utilization technologies. The resource recovery treatment technology includes a solvent extraction method, a water washing method, a microemulsion washing method, a demulsification method, and the like. The sludge innocuous treatment technology includes immobilization treatment, biological treatment, incineration and other technologies. Comprehensive utilization technologies include thermal decomposition, brick paving, and other uses. There are many different treatment technologies for sludge, and each method has its own advantages and disadvantages and scope of application. With the increasingly strict and perfect environmental protection regulations, oil-field mud sand treatment technology will attract great attention. The harmless, resource-based and comprehensive utilization treatment technology of oil-containing sludge sand will become an inevitable trend in the development of oil-containing mud sand treatment technology. Solvent extraction is a commonly used one in sludge treatment technology. It uses the principle of “similar similarity†to select a suitable organic solvent as the extractant. After the organic matter is extracted from the sludge by the solvent, the solvent is distilled from the mixture. It is separated and recycled, and the recovered crude oil is used for refining. US484271 uses the process of extraction oxidation oxidation to treat oily sludge. First, a light hydrocarbon is added to the sludge as an extractant. After extraction, the oil and most of the organic matter are removed. The residual sludge is HNO3 at 200 375 °. C and oxidation treatment under normal pressure conditions. CN02133117. 0 The oily sludge is treated by the technology of "hot extraction-dehydration-solid-liquid separation", the oily sludge is mechanically dehydrated, then mixed with the extraction solvent oil and preheated, mixed uniformly and then subjected to hot extraction-dehydration treatment, and then The solid-liquid separation is carried out, the liquid phase enters the coking unit, the solid phase can be used as a fuel, and the hot-extracted-dehydrated vapor phase is condensed to separate the oil and water. The method is simple in process, requires no special equipment, and has low investment and operation cost. It not only effectively treats oily sludge, but also valuable components are fully utilized without adversely affecting the after treatment device, but energy consumption is relatively low. High, undivided use of various valuable components in the sludge.

Summary of the invention

The invention provides a method for treating sludge, which can fully recover various valuable components in the sludge, and has good industrial application economy. The treatment method of the sludge of the invention comprises the ultrasonic treatment of the sludge by the ultrasonic demulsification dehydration-heat treatment flash-steam distillation method. The specific steps are as follows: (1) the sludge is dehydrated by ultrasonic pretreatment to reduce the water content in the sludge, and the ultrasonic pretreatment dehydration time is 0. . 5 2 hours. The ultrasonic power density is 40 100 W/L (ultrasonic power per liter of sludge) at a frequency of 20 40 kHz and an irradiation mode of 6 lk/6 12 s (ultrasonic continuous irradiation time/ultrasonic interval time). (2) The sludge after ultrasonic dehydration is heated under anaerobic conditions to a temperature range above the boiling point of water and below the cracking temperature of the hydrocarbon substance (100 300 ° C), and then enters the separation tower for flashing. The light oil and water in the flash column are recovered by evaporation condensation. Heavy oil and solids are taken out of the separation column in the form of mud. (3) The solid oil separation (vacuum filtration or pressure filtration or centrifugal filtration) is carried out on the bottom mud, and the heavy oil is recovered as a coking or catalytic cracking raw material. The solid matter is further recovered by steam distillation. At a high temperature of 320 480 ° C, the N 2 purge or water vapor carries the oil and gas. The pressure is controlled at 0. 2 0. 4 MPa, and the solid matter is cured with a curing agent as a fuel or landfill after the treatment. The invention is a novel sludge pretreatment technology, which can greatly improve the dewatering ability of the sludge. Ultrasound refers to sound waves with a frequency above 16 kHz. It is an elastic mechanical wave in a medium that produces a series of conditions close to extremes in water, such as sharp discharges, transient local high temperatures (several thousand degrees), and high pressures ( Hundreds of atmospheres, ultra-high-speed jets, etc. Particle acceleration, shock wave and jet, high temperature and high pressure can destroy the structure of the material and change its physical and chemical properties, which is a primary effect of ultrasonic waves. The secondary waves, radiation waves, acoustic traps, free radicals and oxidants derived from this may also change the nature of the substance to a large extent, triggering a chemical reaction, which is a secondary effect of ultrasonic waves. The pretreatment of the sludge by the above effects of ultrasonic waves can improve the dewatering efficiency of the sludge and enhance the subsequent treatment effect of the sludge. For the sludge, since it is a stable oil-water-solid structure, the above-mentioned ultrasonic treatment, particularly intermittent ultrasonic treatment, can cause the stable structure to oscillate and disintegrate, thereby improving the dehydration efficiency. The heat treatment technique is to heat the sludge to above 100 ° C, and then flash it in a separation column, and steam and hydrocarbons are separated from the separation column. The heavy component hydrocarbons and inorganic materials are used as a sediment to remove light hydrocarbons and water is recovered by condensation. The heavy component hydrocarbons are recovered from the sediment by solid-liquid separation. Since the high-temperature processing equipment is similar to the production equipment of other processes, the existing partial production equipment can be utilized, and the modification can meet the requirements; and the high-temperature treatment process can recover the hydrocarbon vapor by condensation, and the high-temperature treatment process is performed in a closed environment. It reduces the chance of contamination of peripheral facilities. The floor space is relatively small.

BEST MODE FOR CARRYING OUT THE INVENTION Hereinafter, the aspects and effects of the present invention will be further described by way of examples. DETAILED DESCRIPTION OF THE PREFERRED EMBODIMENT 1 A specific embodiment of the present invention (percentage by weight) is illustrated by taking a refinery tank bottom sludge as an example. The invention is particularly suitable for oil sludge with high water content, so the selected sludge has a water content of 83.5%, an oil content of 10.7%, and the rest is a solid substance. The sludge is pumped into the dehydration tank. The dehydration tank is externally connected to the ultrasonic radiation device. The ultrasonic power density is 100 W/L, the frequency is 20 kHz, and the irradiation mode is 6 s/6 s (ultrasonic continuous irradiation time/ultrasonic intermittent time). After ultrasonic dehydration for 1.5 hours, the sludge moisture content can be reduced to 41.3%. The dewatered sludge was heated to 250 ° C and sent to a flash tower for distillation. The top of the tower receives steam and light hydrocarbon vapors, which are condensed and separated by a water separator to obtain a light oil fraction, and the sewage enters the sewage treatment system. The bottom of the flash tower is a slurry of heavy oil and solids. The mud is vacuum filtered to recover heavy oil as a delayed coking feed. The treated mud carries the oil and gas therein with steam at 400 °C. 2MPa。 The pressure of the purge is controlled at 0. 2MPa. The final oil recovery rate was 97.6%. Specific Example 2: A specific embodiment of the present invention will be described by taking a refinery tank bottom sludge as an example. The sludge contains 35% oil and 52% water, and the rest is solid. The process flow is the same as in Example 1. The ultrasonic power density was 80 W/L, the frequency was 30 kHz, and the irradiation mode was 12 s/12 s (ultrasonic continuous irradiation time/ultrasonic intermittent time). After ultrasonic dehydration for 1 hour, the sludge moisture content can be reduced to 17%. The heat treatment heating temperature was 200 °C. 3MPa。 The steam is controlled at a pressure of 0. 3MPa. The final oil recovery rate was 96.4%.

Rights request

A method for treating a sludge, comprising the steps of: (1) dewatering the sludge with ultrasonic pretreatment to reduce water content in the sludge; and (2) heating the sludge after ultrasonic dehydration to a boiling point of water under anaerobic conditions. Above, the temperature range below the cracking temperature of the hydrocarbon material, and then enter the separation tower for flashing, the light oil and water are recovered by evaporation and condensation, and the heavy oil and solid matter are taken out from the separation tower in the form of mud; (3 The heavy oil is recovered after solid-liquid separation of the bottom mud, and the solid matter is further recovered by steam distillation.

2. A method according to claim 1 wherein the ultrasonic power density of step (1) is 40 100 W/L per ultrasonic gas of the liter of sludge and the ultrasonic frequency is 20 40 kHz.

3. A method according to claim 1, wherein the step (1) of the ultrasonic irradiation is 6 12 s / 6 12 s according to the ultrasonic continuous irradiation time / ultrasonic intermittent time.

5å°æ—¶ã€‚ The ultrasonic pretreatment dehydration time is 0. 5 2 hours.

5. Process according to claim 1, characterized in that the heating temperature of step O) is 100 300 °C.

6. A method according to claim 1 wherein the step (3) solids vapor distillation temperature is 320 480 "C.

7. A method according to claim 1 or claim 6 wherein in step (3) the solid matter is subjected to steam distillation, the water vapor therein is carried by the steam.

0. 4MPa。 The pressure is controlled at 0. 2 0. 4MPa.

- Details

-

Published: 09 November 2018

Drilling fluid for well drilling

Drilling fluid, commonly known as mud, is translated into drilling mud in English. It is recognized as the blood of oil field drilling and plays a very important role in drilling operations. Therefore, the drilling fluid is very demanding, mainly in four aspects:

1. Requirements for drilling cycle

Drilling fluid requirements for drilling fluid are low pump pressure (low viscosity), strong sand carrying capacity (high dynamic shear force), low starting pump pressure (low static shear force), good lubrication performance, low friction and low wear (less solid particles) ).

2. To maintain the stability of the wellbore

The drilled formation should be balanced by the pressure column of the drilling fluid and the pressure of the formation. The density of the drilling fluid is stable. When drilling the oil and gas layer, the pressure column of the drilling fluid is used to balance the pressure of the oil and gas. The drilling fluid is required to overcome the performance of the unstable formation, such as the expansion of the wellbore caused by the swelling of the mudstone; the conglomerate and the volcanic rock collide with the water, and the salt rock forms a cave with water, which requires different drilling fluids.

3. Require drilling fluid to protect oil and gas layers

After drilling the oil and gas layer, the drilling fluid is in contact with the oil and gas layer. In order to prevent the drilling fluid from damaging the oil and gas layer, the drilling fluid is required to have small water loss and thin mud cake. After the drilling fluid loses water, the solid pressure difference solid particles form mud on the well wall. The cake ring), the solid phase content is low, and the hydration of the filtrate is low (the chemical action of the filtrate after entering the formation and the liquid in the formation).

4. Protect the environment and ecologyDrilling fluids

often contain crude oil, diesel oil and various oils and contain a large amount of chemical treatment agents. To prevent the environmental and ecological effects of drilling fluids, it is required to use harmless and non-toxic drilling fluids.

Mud has many functions, mainly to carry cuttings from the bottom of the well to the ground. With the rapid advancement of oilfield science and technology, drilling fluids have evolved from just drilling drills to adapting to all aspects of drilling.

1. Clean the bottom of the well, suspend and carry debris, and keep the wellbore clean.

2. Balance formation pressure, stabilize wellbore, prevent well collapse, blowout, and lost circulation.

3. Pass water power to help the bit break the rock.

4. Passing power to the downhole power drill,

5. Cool the drill bit and the drill.

6. Drilling fluid is used for geological and gas logging.

7. Offshore oil drilling and completion projects, including geological, exploration, cementing, casing, logging, logging, etc., need to be completed through the cooperation of mud

Written by GN Solids Control

- Details

-

Published: 01 November 2018

The Mobile Thermal desorption plant (TDU) is a good solution to treat oily sludge and oil based drill cuttings. GN Solids Control developed TDU together with an European company. Most of the major parts are made and imported from European. But TDU is a huge cost for most companies. So mostly, clients will choose oily sludge separation system.

GN Solids Control is the leading manufacturer for oily sludge separation system. For most of other companies, they do only make part of the processing equipment, like most shaker manufacturers are not capable to make centrifuges. Centrifuge manufacturers do not make shale shaker. But GN Solids Control is only focus on the liquid and solids separation. It make the complete line process equipment for liquid / solids separation, like for the oily sludge treatment.

Below is an oily sludge separation system in GN yard. It is for a client and ready for delivery. It is a typical oily sludge separation system with full functions. Below is the major equipment included in the system:

1) Heating and pre-mixing tank unit

2) Oil skimming system

3) Solids separation unit. It is the 1rst separation treatment. The unit includes a high G force shale shaker for coarse solids separation, and a high speed decanter centrifuge for fine solids separation

4) After that, it is the 2nd washing and separation unit. The unit includes a washing tank and another high speed decanter centrifuge.

5) A disc centrifuge is used after the 2nd centrifuge separation. The disc centrifuge is used for 3-phase separation. After disc centrifuge, it is solids, water and oil.

6) The oil water separator is also used after disc centrifuge is further remove the water in the oil;

7) A water treatment system is used as the final stage to purify the recovered water from the oily sludge system.

The oily sludge separation system utilizes heating and chemical washing method to treat the oily sludge. You can contact GN sales team, or visit GN website to see the jobsite performance of the chemical heating and washing system for oily sludge.

http://www.gnsolidscontrol.com/video/oil-sludge-treatment-test-unit-working-video

- Details

-

Published: 27 October 2018

GN Solids Control offers different sizes and lengths Screw conveyors to carry drill cuttings from barite recovery decanter centrifuge, solids control shale shakers, mud cleaner Desander and Desilter to mud cutting waste pits eliminating water-jetting. The Screw conveyors can also feed or discharge drill cutting from other solids control equipment, like to feeding for High G dryer shale shaker or Vertical cuttings dryer, to transfer the discharges cuttings to skips or other drilling waste containers.

GN Solids Control screw conveyoraugers can be provided with mechanism of automatic emergency cut off and switch off the power supply to the auger when the covers / gratings around the auger are opened / removed or not closed or not appropriately fixed.

All augers are equipped with explosion proof limit switches for all auger covers for each sections. There are controls inside the motor starter control panel for the limit switches. In case any auger covers are opened / removed / not fixed appropriately, the auger will be switched off and be stopped.

Besides the mechanism of automatic emergency stop, GN Solids Control makes screw conveyors with other optional safety protections. Below are some of the optional safety protection provided by GN.

1) GN screw conveyor augers can be equipped with Electromagnetic brake motor for immediate stop without delay. For normal motors, the auger will be stopped after some seconds while press E-stop. With the electromagnetic brake motor, there will be no delay.

2) GN screw conveyor augers can be equipped with full Length Safety Grab Wires

3) GN screw conveyor augers can be equipped with mechanical speed reducer for variable speed control.

Screw conveyors is a normal equipment popular used for drilling mud solids control system and drill cuttings treatment systems. For more information of the screw conveyor or other drill mud and cuttings treatment system, please contact GN 7×24 hour service line.

- Details

-

Published: 24 October 2018

Many manufacturers are labeling their screens as “conforming to API RP 13C. But few companies have the API RP13C testing report. They do not really know what does API RP13Cscreen means? How they can say their screens are “conforming to API RP 13C. They must supply the test report and data from the authorized third party as support and confirm.

GN is the onlyoneChinese company who has the API RP 13C third party test report according to API RP 13C. This means all the data on GN made screen labels are fromlab test, it is accurate. But most other China competitors cannot offer the API RP13C testing report. If clients get screen from other suppliers without API RP13C testing report, or they do not have the full line report to cover all API sizes per API RP13C standard. It means the data on the screen tag or label is not accurate. Maybe the API 140shale shakerscreen they sold is actually API 100 or API 170. With the wrong screen opening, rig site people are difficult to control the mud weight and mud flow. That is the root reason that why many big companies do not accept these types of screen from the suppliers without full line API RP13C testing report. They only accept API RP 13C compliant screens.

GN Solids Control is one of the biggest manufacturers for oil field replacement shale shaker screens. GN Solids Control has Research and Development department specialized on high quality replacement screens development. GN owns the full line production equipment to make composite material screens by from raw material to final screen. It ensures a better quality control for all process and materials.

GN Solids Control can make high quality replacement screens for most of the popular shaker models. Furthermore, GN Solids Control can make customized design screens, or make screens with clients’ legal company name, logo, package and branding.

- Details

-

Published: 15 October 2018