What is the function of drilling waste cuttings?

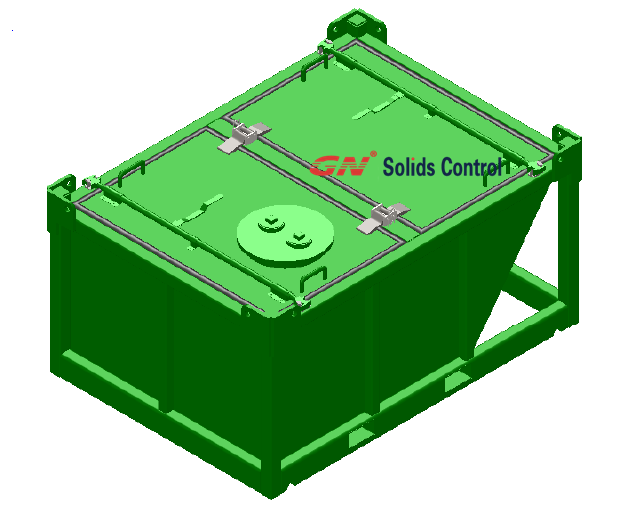

Drilling waste cuttings container is also called drilling waste cuttings bins, mud cuttings skips. GN specially designed drilling mud cuttings skips are used for transportation and safe handling of hydrocarbon contaminated drill cuttings. It is can be used for offshore to and from offshore platforms. The drilling waste cuttings containers provide a safe and efficient means of containment of drilling waste for transport to treatment and disposal sites.

GNYXH-030 drilling mud and cuttings container meets DNV lifting regulations for offshore applications. The GNYXH-030 drilling waste mud and cuttings container is completed sealed to avoid spill during transportation. And the cover is designed with an easy lock and unlocks system for fast opening and closing. It is the ideal container to meet the HSE regulations for hazardous waste movement.

It can stock and move drilling mud cuttings from one place to another place, or collect the waste cuttings to different equipment or system for treatment, like high G drying shaker, high speed centrifuge, vertical cuttings dryer, solidification unit or TDU.

GN brand drilling mud and cuttings container can meet below features:

1) GN brand drilling mud and cuttings containers are designed and manufactured per DNV 2.7-1/ EN12079 standards.

2) Certified Slings complete with shackles are provided according to DNV 2.7-1/EN1207 standards

3) GN brand drilling mud and cuttings containers are completed sealed to avoid spill during transportation

4) Specially designed cover with Light weight, it is easy and convenient for operators to open and close it.

5) The cuttings container top cover be can opened fully. Maximum the ability to fill waste cuttings. Improve the efficiency of hazardous waste logistics.

6) The drilling cuttings containers can be stacked together to save shipping space and easy for stock.

7) Rigid construction for long life time.

8) The drilling mud and cuttings containers are with sloped tank bottom for easy and fully discharge.

- Details

-

Published: 25 December 2016

2 sets 14 inch high quality decanter centrifuge was dispatch to the sea port from GN Solids Control Beijing factory this week. After 1 month sailing on the ocean, they will arrive South America to client's jobsite. The client will use it in his mud solids control system.

It is a 14 inch popular size 2-phase decanter centrifuge. The centrifuge is widely used for mud solids control and drilling waste management. It is also a very good choice for oily sludge processing projects.

Firstly, 14 inch centrifuge can be used in drilling fluids mud recycling system, to recovery the barite for reuse. In the case of the mud is weighted and it is not suitable for drilling activities, the 14 inch decanter centrifuge can be used to remove the fine solids, and enable the drilling fluids qualified for the mud system.

Secondly, the decanter centrifuge can be used after high G drying shaker and vertical cuttings dryer to treat the drilling cuttings from solids control system.

The cuttings from solids control system, especially from shale shaker, desander, desilter, mud cleaner, contains high quality usable drilling fluids. From one side, the usable drilling fluids are valuable. It is better to recovery as more as possible to save cost. From another side, the high percentage drilling fluids makes the liquid percentage is too much high, it is not convenient for movement, and also the oil content is too much higher, it is hazardous to the environment. It cannot be discharged. Decanter centrifuge is one of the essential equipment used to retreat the drilling cuttings.

Another popular application of decanter centrifuge is for oily sludge separation. There is a variable source of oily sludge: from refinery, from drilling, from tank cleaning, etc…The oily sludge with various percentage of solids and water. Decanter centrifuge will be used together with chemical dosing system to process the fine soil in the oily sludge.

- Details

-

Published: 17 December 2016

GN Solids Control is a professional manufacturer on waste management on drilling field.

GN Solids Control offers complete solution of 3 phase separation: soil, water and oil separation. GN Solids Control can treat various types of oily waste, especially from drilling field and refinery companies.

What kind of waste GN Solids Control can treat? Below are some of the items, but not limited to the below items:

1) GN Solids Control can offer solution to the waste pit generated from drilling activities. There are huge quantities of waste. It is mixture of heavy oil, diesel oil, drilling cuttings, disposed drilling fluids, rain water, etc…

2) GN Solids Control can offer solution to the sludge waste from refinery. The waste normally contents sand, soil, crude oil, water and other kinds of waste oils. GN Solids Control can separate the solids phase, and get oil and water. The oil can be used to get oil products, and water can be reused for industry.

3) GN Solids Control can offer solutions of waste water and slurry generated from underground constructions, like piling, micro tunneling, HDD, etc… In more and more countries, the government as higher standard on industry and construction field waste water discharge. They cannot discharge the slurry directly. If they let the professional waste water treatment company to do the job, they charge per ton, it is high cost for the long run.

What equipment GN specially designed for waste management? Below are some of GN design waste management equipment:

1) High speed centrifuge and Big bowl centrifuge, Full hydraulic drive centrifuge

2) Vertical cuttings dryer

3) Drill cuttings solidification unit

4) Chemical dosing system

5) Thermal desorption unit

6) Vacuum pump

7) Oil/ water separator

8) Automatic tank cleaning system (ATC)

GN Solids Control offers customized solution to suit clients special request. If you have any question, welcome you contact GN international service center for support.

- Details

-

Published: 04 December 2016

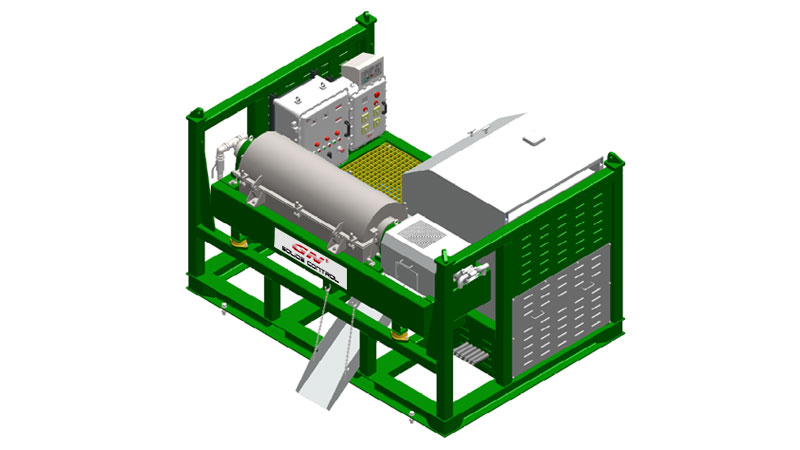

GNLW363D-FHD is a full hydraulic drive dual system decanter centrifuges. It is with full hydraulic drive and the unit is furnished complete with electric motor and controls.

The GNLW363D-FHD full hydraulic drive dual system decanter centrifuge is a 2-phase separation centrifuge. Its maximum treating capacity can reach up to 200 GPM. The operation bowl speed is variable from 0 to 3600 RPM, with internal centrifugal acceleration exceeding 2610 G’s. A self-contained hydraulic system supplies pressure to the hydraulic motors that drive the bowl and the differential conveyor that operates at 0 to 70 RPM. Continuous monitoring of feed characteristics is used for automatic conveyor boost and protects the machine from overloads.

The FHD centrifuge is designed for minimal maintenance and may be used in Class I, Division 1, Group C and D areas. The bowl of the GNLW363D-FHD full hydraulic drive dual system decanter centrifuge are made from Duplex SS2304/SS2205 from centrifugal casting. The screw protection of the FHD centrifuge is Tungsten Carbide Tiles long life and minimal maintenance. The solids discharge port is with Tungsten Carbide Inserts for long lifetime and easy maintenance.

GN Solids Control is worldwide leading manufacturing on industry centrifuge. GN owns the advanced processing machine for centrifuge production. And GN owns a professional R&D department specialized in centrifuge development.

Viscotherm and ROTODIFF® from Switzerland are leading brand for centrifuge hydraulic driving system. For GNLW363D-FHD Full hydraulic drive (FHD) centrifuge, the hydraulic system is from Viscotherm. The hydraulic motor is from OTODIFF® from Switzerland. GN and Viscotherm has been jointly working together to develop the Full hydraulic drive centrifuge for international clients to meet the highest standard.

And Viscotherm and ROTODIFF® from Switzerland are leading brand for centrifuge hydraulic driving system. GN and Viscotherm has been jointly working together to develop the Full hydraulic drive centrifuge for international clients to meet the highest standard.

The hydraulic bowl and scroll drive system drives both the hydraulic motor ROTODIFF and the bowl of a decanter centrifuge from hydraulic pump unit by two hydraulic oil circuits.

The advantage of the FHD centrifuge is for use in high temperature ambient for heavy mud with flexible bowl and differential speed. The compact one skid design makes it easier for rig up.

- Details

-

Published: 04 December 2016

Decanter centrifuge is a very normal machine for drilling mud treatment and for different type of waste management, like waste oil treatment, waste water treatment, and sand purification.

For different materials and different treating purpose, operator should choose the most suitable separation speed and G force in order to get the best performance and separation result. In this case, the variable frequency control of a decanter centrifuge is necessary.

GN Solids Control is a worldwide famous brand for drilling mud treatment and variable type waste management application. GN company offer different solutions to get the variable speed control of a centrifuge. Below is a general idea of the most normal 3 designs. Operator can compare and choose the most suitable design per his demands and the job site condition.

1) The most simply type variable speed control is Mechanical gearbox drive decanter centrifuge. For this kind of centrifuge, operator can get another fixed speed by using a different size of pulley. It is simply for operation and maintenance, and cost effective. And the mechanical gearbox drive centrifuge is especially suitable for high temperature like desert. If the jobsite is only need to use a few speeds, and it does not need to change speed frequently, the Mechanical gearbox drive variable speed decanter centrifuge is more suitable.

2) Another luxury variable speed centrifuge design is fully hydraulic drive centrifuge. The FHD centrifuge changes speed from the hydraulic drive system. The hydraulic drive system is suitable for high temperature area. But as you know, the hydraulic system itself is complex for operation and maintenance. And it is cost higher.

3) Another popular design of Variable frequency Drive (VFD) decanter centrifuge is changing speed through the speed of motor. They use frequency drive to change the speed of the motors to get different separation speed.

For more information of GN variable speed control decanter centrifuge technology, welcome you contact GN group with its 7 by 24 hours services center:

This email address is being protected from spambots. You need JavaScript enabled to view it.

- Details

-

Published: 20 November 2016

Chemical dosing system, is also named as dewatering unit, it is a mixing & storage system used to enhancing chemicals, or acid, alkali to other system or materials to reach a certain purpose. It is widely used in drilling waste management system, waste oil recovery system, waste water treatment system, soil clarification system, and other liquid treatment applications. Below are some of the applications of the dosing chemicals:

1) The chemical dosing system can be used to mix and prepare flocculent or polymers to remove the fine solids from waste oil or waste water. Mostly, the chemical dosing system is used together with decanter centrifuge separator. The separation point of centrifuge is 2 ~ 5 microns. Particles smaller than 2~ 5 microns is out of the range of centrifuge separation. After using flocculent, the ultra-fine particles and be flocculated to bigger size for centrifuge remove.

2) The chemical dosing system can be used to mixing and it can automatically add acid or alkali to liquid to reach the suitable PH degree. Mostly, the waste liquid is not neutral. It is either acidic or alkaline. During treatment, people should to make it to be neutral to reduce its harm to the environment. Based on the liquid situation, acid or alkali will be add to the system to neutralize the PH degree.

3) The chemical dosing system can be used to stock demulsifier for oily sludge separation system. After dosing the demulsifier, the viscosity of the oily sludge can be reduced, then it can be suitable for mechanical separation, like high G shaker, vertical cuttings dryer or decanter centrifuge. Decanter centrifuge is one of the most common equipment used together with chemical dosing system. According to different treating capacity requirement and the separating result, there are different sizes and different speed decanter centrifuge for option from world famous brand GN Solids Control. The bowl size varies from 9 inch, 14 inch, 18 inch, 22 inch and 30 inch.

- Details

-

Published: 21 October 2016