GN Solids America is a branch company of GN Solids Control. GN Solids America is located in 6710 Windfern Rd, Houston, TX 77040, USA . As a leading brand for mud solids control, drilling waste management and replacement shaker screen, GN Solids Control owns many branches worldwide in order to offer fast service and delivery the GN customers.

GN Solids America has office and big warehouse in Houston TX, USA. High quality replacement shaker screen is a main business of GN Solids America. GN Solids America screen stock covers all API size and nearly all the popular shaker models. Below is some of GN Solids America screen stock model.

1) G594 is the most hot sale screen model. G594 is a composite material shaker screen. G594 screen is interchangeable with many different shaker models. It can be used for GNZS594 series shale shaker and mud cleaner, GN high G drying shaker and double deck shale shaker. G594E screen is also fully interchangeable with Swaco Mongoose PRO shaker and mud cleaner, with MI-Swaco MONGOOSE PT & MEERKAT shale shaker and mud cleaner.

2) B635 is another popular shaker screen model. Besides used for GN own brand shale shaker, it is compatible with NOV Brandt Cobra, King Cobra, Mini Cobra, Venom, LCM-2D, LCM-3D shale shaker or mud cleaner or mud conditioner.

3) GN Solids America has screen stock for NOV Brandt VSM300 offshore shale shaker. It is high quality composite material screen for VSM300 scalping deck and primary deck. It is with longer time, bigger blanked area and better conductance compared with the OEM metal frame screens.

4) High quality flat screen and PMD screen for all Derrick shaker model: for Derrick Hyperpool shale shaker, Derrick Dual Pool 600 shale shaker and mud cleaner, Derrick FLC2000, FLC500, FLC503,FLC504, FLC48-30 series shale shaker and mud cleaner.

GN screen stock is not only limited to these models. GN Solids America can also make customized screen for clients’ own brand shaker, or special design screen for special applications / purpose. If you have any demands on replacement screens.

- Details

-

Published: 11 July 2017

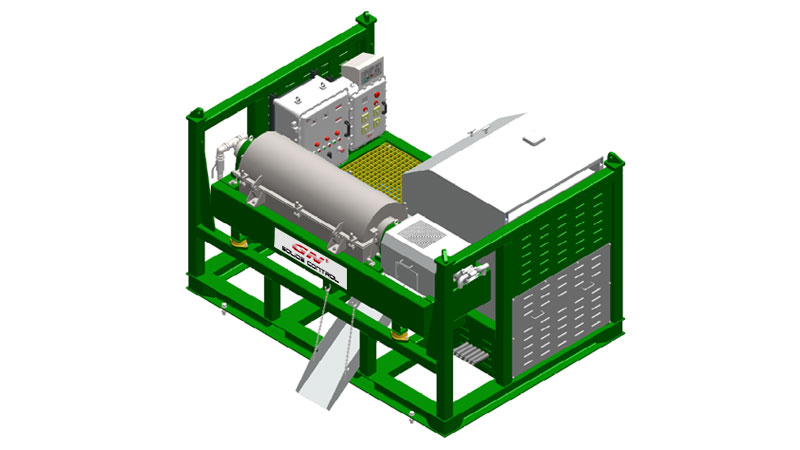

Full hydraulic drive (FHD) centrifuge is popular for drilling waste and drilling cuttings treatment project in remote areas and for hazardous environment. For many big projects, the end user will appointed to only accept Full hydraulic drive (FHD) centrifuge. They do not want a variable frequency drive (VFD) centrifuge as an instead. Why? The reason is as bellows.

1) Full hydraulic drive (FHD) centrifuge is high technology then the VFD centrifuge. Many people prefer the new technology. They think it is better.

2) Full hydraulic drive (FHD) decanter centrifuge change bowl speed and the conveyor speed (differential speed) through the hydraulic system. It is more sensitive and has a wide range. The VFD centrifuges change bowl speed and conveyor speed by changing the main drive and back drive motor frequency. The centrifuge bowl speed and differential speed is with logical relation. When the motor frequency is changed, the motor running speed will be changed, and then the centrifuge bowl speed and differential speed will be changed accordingly.

3) Unlike the VFD drives, the hydraulic system will not generate extra heat when the operators change the hydraulic system to change the centrifuge speeds. The hydraulic system itself can bear a high temperature. It is suitable for high temperature areas.

The Variable frequency drive centrifuge is control by VFD drives insides the VFD control panel. The VFD centrifuge is a sealing panel with VFD drives and other electrical components inside. The VFD drives will generator much heating during working. Other electrical components will also generate heat during working. In low temperature ambient or in winter, the heat is not a problem. But in the high temperature areas in summer, the heat will cause troubles. If there is not a very good cooling system, the heat will damage the VFD drives and electrical components.

GN Solids Control offers different sizes high quality full hydraulic system for mud solids control, for waste management, drilling cuttings management and other solids liquid separation applications.

- Details

-

Published: 04 July 2017

Decanter centrifuge and chemical dosing system is normally used together as dewatering unit to treat and recovery waste water from drilling rig activities, HDD and construction field waste water treatment, and industry waste water treatment.

Recently, GN Solids Control finished a decanter centrifuge with chemical dosing system for a Korea client. The centrifuge dewatering unit will be used to treat waste waters.

The centrifuge dewatering unit for Korea customer is including below items:

1) 1 set of GN high speed decanter centrifuge, model GNLW363-VFD. It is the most popular and hot sale centrifuge model from GN Solids Control. It is a 14inch bowl decanter centrifuge. It is widely used in oil and gas drilling field, for waste management projects, and for waste water treatment.

2) 1 set of screw pump to feed for the decanter centrifuge GNLW363CG-VFD. The screw pump is made by NETZSCH, it is a German brand famous for high quality screw pump. They have international sales and aftersales support. GN Solids Control is VIP clients of NETZSCH China. All GN centrifuges are equipped with NETZSCH pump, they have partnership agreement. So GN can get very good price support from NETZSCH company.

3) 1 full set of chemical dosing system build in a 20ft container. It is GN standard model containerized chemical dosing system for dewatering unit. Its model is GNDW-2000. The chemical dosing dewatering unit is equipped with a 3-chamber automatical polymer mixing and dosing system. And there is a separate liquid chemical dosing system. In this case, the dosing system is more flexible for more applications.

Further model, there are some centrifugal pumps together in the order for liquid and mud transfer between difference process.

The clients cooperated with GN nearly 10 years. They will used the centrifuge dewatering unit together with his GN shale shaker system to treat the waste water generated from HDD activities.

- Details

-

Published: 23 June 2017

GN Solids Control is a leading manufacturer on drilling rig mud solids control system, drilling cuttings treatment system, and oily sludge separation system. GN Solids Control is a private company without any government background. GN Solids Control main market is international market. Its solids control equipment and drilling waste management equipment have been exported to 74 countries and regions till now.

China National Offshore Oil Corporation ("CNOOC") is the largest offshore oil & gas producer in China. CNOOC is a state-owned company operating directly under the State-owned Assets Supervision and Administration Commission of the State Council of the People's Republic of China.

In year 2016, GN Solids Control offered an oily sludge separation system for CNOOC. The project destination is Uganda in Africa. GN Solids Control offered a turnkey solution for the drilling cuttings treatment project of CNOOC. Till now, the system have been running for 1 year. Per feedback from jobsite, the performance is good, CNOOC are very happy with the system.

The oily sludge separation system for drilling cuttings treatment is including below unit:

1) Automatic drilling cuttings taking unit: The unit includes portal crane, Submerged slurry pump, high pressure gun and supporting skids. It is used to transfer cuttings from the drilling cuttings pit to

2) Automatic drilling cuttings transfer unit: The unit includes high pressure washing system, V-hopper, screw conveyer, material tank and a skid for all above items.

3) Drilling cuttings shearing and separation unit: the unit includes following items: shear pump, high G shale shaker, surging tanks, transfer pump and a skid for all above items.

4) High speed solids washing system: this unit including a washing tank, mud agitator, transfer pump, high speed decanter centrifuge, automatic chemical dosing system, etc…

5) Ultrasonic oil-water separation system. This system is used to get clean water and oil. And there will be transfer pumps for the recovered oil and water.

- Details

-

Published: 16 June 2017

Recently, GN Solids Control finished a complete decentering centrifuge mud treatment and recycling system for an America project. The mud treatment system is used for an underground construction project, to remove the sands and recovery the drilling mud for HDD rigs and micro tunneling machines.

For fast movement and flexible jobsite layout, GN Solids Control design the centrifuge dewatering system with different operation modular. Clients can choose whatever parts they need per material conditions.

Modular 1: Hopper connection unit. Frankly speaking, it is a big V bottom tank with a hopper on top to collect waste mud. And there is a screw conveyer under the V bottom tank to transfer the water mud to the treating systems.

Modular 2: Coarse shale shaker separation unit. It is the first stage separation unit. It is a big volume shale shaker with coarse shaker to separator the big rocks and big size solids inside the mud. The recovered mud with fine solids will goes to the next processing equipment.

Modular 3: Solids Control shale shaker separation unit. It is the second stage solids control separation processing unit. The mud from the first stage coarse shale shaker will be pumped to the second solids control shale shaker to remove the big size solids. The clean mud underflow shale shaker screen will falls downs to the solids control shaker tank, and be pumped to the second processing unit.

Modular 4: High speed decanter centrifuge unit. It is the third stage separation unit. The clean mud recovered from solids control shale shaker will fall down to the shaker tank. There will be a screw pump feeding for the high speed centrifuge. The high speed centrifuge feeding pump will suck mud from the solids control shaker tank, and feed to the centrifuge. The high speed centrifuge is used to remove the fine solids inside the mud.

Modular 5: Chemical dosing dewatering unit. Decanter centrifuge can only remove the fine solids above 2 microns to 5 microns. If there is a high content of ultra-fine sand inside the centrifuge mud, chemical dosing dewatering unit is needed. It is used to dosing flocculant to the clean mud feed to high speed centrifuge, and increase the solids remove efficiency.

It is the second construction mud dewatering system for the American client. If you want more information, please feel free to contact GN Solids Control, or GN Solids America.

- Details

-

Published: 09 June 2017

GN Solids Control is a leading solids control manufacturer from China. GN Solids control main market is for international clients. As GN do not have special relationship with China government, CNPC companies, or SINOPEC companies, it is difficult for GN to sell to the major drilling companies and services companies. GN Solids Control can only make high quality products with competitive price, and offer reliable services for international customers.

It is good that after years of hard working and fast development, GN Solids Control becomes a leading brand for mud solids control and waste management equipment. And also GN Solids Control becomes an international famous brand. Now GN Solids Control has 3 international branches: GN Solids America in Houston, GN Solids Control Russian, and GN Solids Control Australia. GN Solids Control set up international warehouse and service center to offer fast and on time services to worldwide clients.

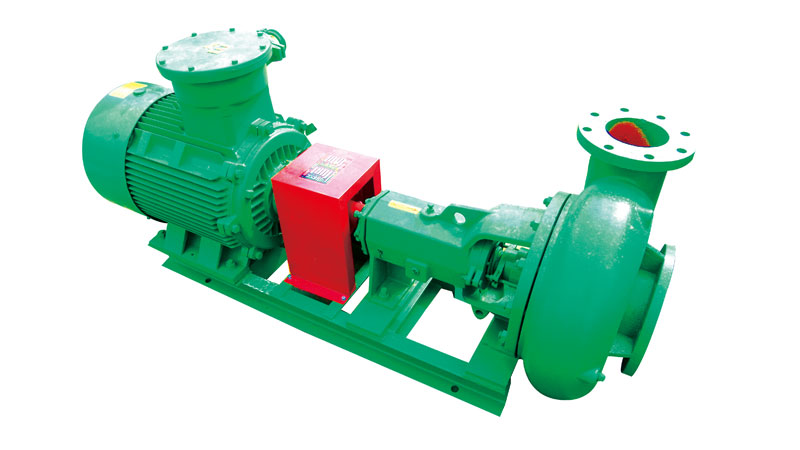

High quality interchangeable centrifugal pump and pump spare parts are a main business of GN Solids Control company. As we all knows, Mission type pump is a most popular centrifugal pump design for oil and gas drilling field. Many clients own Mission pump. Centrifugal pump requests many high consumable parts. And even the centrifugal pump itself cannot last for long time. Per different job site condition, the total Mission centrifugal pump should be changes. GN Solids Control B generation centrifugal pump is completely interchangeable with NOV Mission pump, no matter the pump design or the footprint. It means clients can use GN brand centrifugal pump to replacement the old Mission pump, and they do not need to make any changes.

All GN Solids Control centrifugal pump is mechanical seal for reliable performance and longer lifetime. Below is the main centrifugal pump model offered by GN Solids Control:

GNSB8x6B-14J, GNSB8x6B-12J, GNSB8x6B-13J, GNSB8X6B-11J, GNSB6x5B-13J, GNSB6x5B-10J, GNSB6x5B-12J, GNSB6x5B-9.5J, GNSB5x4B-13J, GNSB5x4B-11J, GNSB5x4B-12J, GNSB5x4B-10J, GNSB4x3B-13J, GNSB4x3B-12J, GNSB4x3B-12J, GNSB4x3B-10J, GNSB4x3B-11J, GNSB4x3B-9.5J

Furthermore, GN Solids Control can offer all the spare parts for NOV mission pump, including mechanical seal, pump casing, oil seals, bearings, couplers, housings, impellers, etc…

- Details

-

Published: 04 June 2017