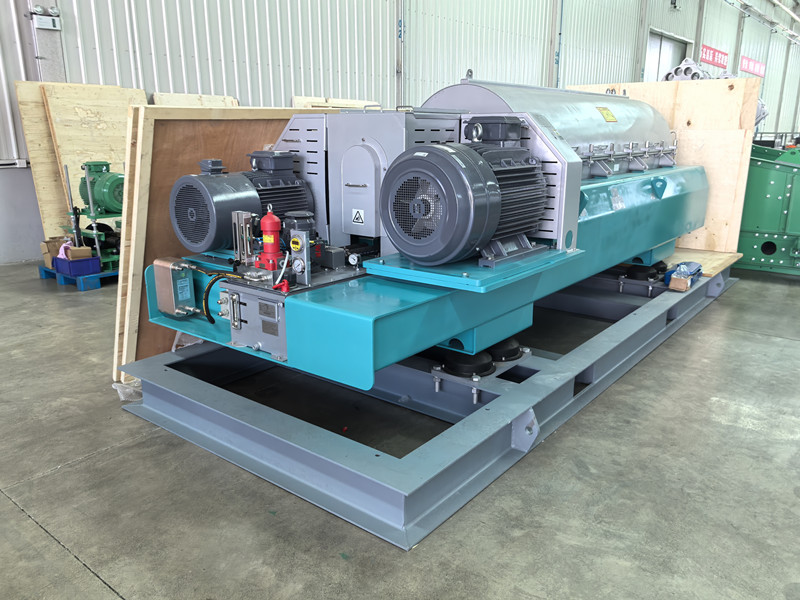

We are pleased to announce that GN Separation has shipped a GNLW-654 T-Series Dewatering Decanter Centrifuge to our European client. This high-performing machine will significantly enhance sludge dewatering operations, delivering higher dryness, efficiency, and reliability under demanding industrial conditions.

- Details

-

Published: 12 September 2025

Recently, GN Separation successfully finished the factory acceptance testing of a GNLW654 Decanter Centrifuge. This unit, designed with features that enhance operational flexibility and durability, is now ready to be shipped to a major client in Europe.

Dual-Motor Drive System: Precision Control for Dynamic Operating Conditions

The outstanding performance of the GNLW654 dewatering centrifuge is largely attributed to its dual-motor drive configuration. This design allows operators to precisely adjust both the rotational speed of the main bowl and the differential speed between the bowl and the screw propeller. As a result, separation efficiency can be optimized under various process conditions. Whether dealing with viscous slurries, abrasive tailings, or feeds with fluctuating compositions, the dual-motor system enables quick adaptation to material changes, minimizing downtime and maximizing throughput.

Continuous Lubrication: Ensuring Reliable Operation Under High Pressure

To ensure uninterrupted performance in demanding 24/7 operational settings, the GNLW654 features a fully automated thin-oil lubrication system. Unlike grease-lubricated models, this closed-loop system continuously circulates oil to both main bearings, effectively dissipating heat and preventing premature wear. By maintaining optimal lubrication levels even under extreme loads, the system extends bearing lifespan, reduces maintenance frequency, and lowers lifecycle costs.

Tungsten Carbide Wear Protection: Designed for Longevity

Given the abrasive nature of slurry processing, GN Separation has fitted the GNLW654's rotating assembly with tungsten carbide wear plates and liners in high-contact areas. These hard components are well-known for their resistance to erosion and corrosion, protecting vulnerable parts such as the screw flights and feed zone from degradation. This results in a significant increase in the mean time between failures, with some clients reporting longer service intervals for wear parts.

Synergy with Flocculation Dosing Systems: Enhancing Separation Efficiency

The capabilities of the GNLW654 are further enhanced when used in conjunction with GN Separation's chemical dosing units, offering a comprehensive solution for solids-liquid separation challenges. In wastewater treatment, the centrifuge works alongside polymer dosing systems to improve particle aggregation, facilitating the efficient removal of suspended solids and biological sludge.

In mining applications, this combination is equally transformative. By pre-treating tailings pulp with flocculants, the GNLW654 achieves higher solids capture rates, which is crucial for sustainable tailings management. Recent field trials of GN's tailing dewatering centrifuge at a copper mine in Mexico showed a reduction in the solids content of clarified tailing slurry, significantly decreasing waste disposal.

Global Reach: From Municipal Plants to Mining Industry Leaders

In recent years, GN Separation's decanter centrifuges have gained a strong reputation for reliability across various industries. The GNLW654, with its modular design and scalable capacity, is attracting interest from European municipalities looking to upgrade their aging wastewater infrastructure and mining corporations aiming to modernize their tailings processing.

As the GNLW654 prepares for its transcontinental journey, GN Separation reaffirms its dedication to advancing separation technology. Focusing on durability and process integration, the company is committed to continuing its support for customers in achieving cleaner and more efficient operations.

- Details

-

Published: 12 September 2025

GN Separation has recently finished factory testing on two sets of GNLW364-VFD decanter centrifuges. These units are now en route to an overseas environmental company, where they will be deployed in municipal sludge dewatering projects.

Decanter Centrifuges: A Modern Solution for Sludge Treatment

Decanter centrifuges play a crucial role in wastewater treatment and sludge management. Their key advantage lies in the ability to efficiently separate solids from liquids under strong centrifugal forces. Unlike traditional methods such as belt presses or filter presses, decanter centrifuges operate continuously. This continuous operation not only cuts down on labor costs but also enhances the stability of the entire process.

Key Applications in Sludge Dewatering

1. Municipal Wastewater Treatment

Decanter centrifuges are highly effective at reducing the moisture content of municipal sludge. They can bring it down from roughly 98% to a range of 75 - 85%. This reduction is of utmost importance for cost-effective landfilling, incineration, or resource recovery. For example, GN Separation's GNLW364 series has already been put into use in municipal plants in the Middle East and Europe. Its high throughput and compact design help optimize the layout of these plants.

2. Industrial Sludge Handling

In industries like petrochemicals, textiles, and food processing, the sludge often contains hazardous substances, such as heavy metals or organic pollutants. GN Separation's centrifuges are well - equipped to handle such challenges. They are fitted with corrosion - resistant materials, including SS2205 duplex stainless steel and tungsten carbide - lined components, ensuring durability even in harsh and aggressive environments.

Features of GN Separation's Decanter Centrifuges

1. Triple Variable - Frequency Control System

Conventional centrifuges usually have fixed parameters. In contrast, GN's dewatering centrifuge utilizes three independent variable - frequency drives for the bowl, differential screw, and feed pump. This setup allows for real - time adjustments, providing greater flexibility and control over the dewatering process.

2. Material Science Innovations

- Bowl Construction: The bowl is made of centrifugally cast SS2305 duplex stainless steel. This material offers higher corrosion resistance compared to standard 304 steel, which extends the service life of the centrifuge, especially in chloride - rich environments.

- Screw Conveyor: The base of the screw conveyor is made of 316L stainless steel, and it is laser - clad with tungsten carbide tiles. This combination results in a low wear rate, effectively doubling the maintenance intervals compared to conventional designs.

3. Smart Monitoring and Safety

The centrifuge features an integrated HDMI - touchscreen PLC interface. This interface provides real - time data on crucial parameters such as vibration, temperature, and torque. Additionally, it can issue predictive maintenance alerts, helping to prevent potential issues before they cause significant problems.

4. Customization for Global Challenges

GN Separation's engineering team works closely with clients to develop tailored solutions. For instance, the 4:1 length - to - diameter ratio is crucial for achieving low moisture content in sludge. Moreover, explosion - proof variants are available, enabling safe operation in oil and gas projects.

Global Recognition and Future Prospects

As the two GNLW364 - VFD units set off on their overseas journey, GN Separation further solidifies its position as a global leader in separation technology. The company continues to drive innovation while keeping sustainability at the core of its operations, paving the way for a more efficient and environmentally friendly future in sludge dewatering.

- Details

-

Published: 07 September 2025

Recently, GN Separation successfully installed, commissioned, and officially launched a complete set of vibrating screens in a key gasification slag treatment project for an energy group in Inner Mongolia. This achievement underscores the recognition of GN Separation's technological prowess and high-end equipment in solid-liquid separation and fine classification by large-scale energy enterprises, providing vital technical support for their solid waste resource utilization and environmentally sustainable production practices.

Project Challenges and GN's Tailored Solutions

Gasification slag, a byproduct of the coal chemical process, requires a multi-step treatment approach involving slag separation, classification, and dewatering. These steps impose stringent demands on the reliability, efficiency, and dewatering performance of screening equipment. To meet the unique needs of this project, GN Separation's technical team devised a customized intelligent screening solution.

Core Slag Separation: Box-type Exciter Linear Screening

GN Separation's large linear vibrating screen utilizes a robust box-type exciter as its vibration source, ensuring powerful, stable operation and extended service life. Its superior linear motion trajectory enables it to efficiently handle large volumes of material with varying slag quality, achieving initial efficient separation and medium removal of gasification slag. This sets a solid foundation for subsequent processing stages.

Fine Classification: Synergistic Frequency Vibrating Screen

The synergistic frequency vibrating screen, a flagship product of GN Separation, is celebrated for its innovative synergistic frequency coordination technology. This technology allows precise control over the vibration frequency and amplitude of the screening surface, facilitating fine classification of materials with different particle sizes. With high separation accuracy and substantial processing capacity, it effectively meets the customer's requirements for classifying gasification slag into different particle size fractions, significantly enhancing the material's added value.

Efficient Dewatering: Small High-frequency Fine Screen To address the high-frequency and low-moisture demands of the dewatering section, the small high-frequency fine screen plays a pivotal role. Equipped with a high-frequency vibration motor, it generates high vibration frequency and small amplitude, effectively breaking the surface tension of water and promoting rapid water separation. This significantly reduces the moisture content of the filter cake. Its compact design makes it ideal for spatial arrangements in process steps, demonstrating exceptional dewatering efficiency.

To address the high-frequency and low-moisture demands of the dewatering section, the small high-frequency fine screen plays a pivotal role. Equipped with a high-frequency vibration motor, it generates high vibration frequency and small amplitude, effectively breaking the surface tension of water and promoting rapid water separation. This significantly reduces the moisture content of the filter cake. Its compact design makes it ideal for spatial arrangements in process steps, demonstrating exceptional dewatering efficiency.

Project Outcomes and Future Prospects

All equipment has been successfully installed and commissioned, operating smoothly with all performance indicators meeting or surpassing design expectations. The successful implementation of this system has enabled the enterprise to achieve efficient and environmentally friendly treatment of gasification slag, promoting resource recovery and utilization while reducing operational costs. This demonstrates favorable economic and environmental benefits.

The success of this collaboration reaffirms the significant advantages of GN Separation's mining vibrating screen products in terms of technological sophistication, equipment reliability, and solution professionalism. GN Separation will continue to adhere to its philosophy of "technological innovation and quality first," consistently providing more efficient and intelligent screening solutions for industries such as coal, mining, chemicals, and environmental protection. It is committed to working hand in hand with customers to advance green and sustainable industrial production.

About GN Separation

GN Separation is a high-tech enterprise dedicated to the research and development of solid-liquid separation and material screening and conveying technologies, as well as equipment manufacturing. Its product range includes various equipment such as vibrating screens, dewatering screens, and classification screens, which are widely applied across multiple fields. GN Separation enjoys a high reputation in both domestic and international markets for its exceptional quality and attentive service.

- Details

-

Published: 29 August 2025

GN Separation is pleased to announce the completion and delivery of our new Material Separation Testing Workshop, designed to support clients in evaluating equipment performance and selecting the most suitable solution for their applications. This dedicated facility integrates multiple testing modules, enabling both customer material testing at GN and on-site testing at customer facilities.

- Details

-

Published: 27 August 2025

Recently, GN Separation proudly announced the official opening of its state-of-the-art Pilot Testing Workshop at its manufacturing headquarters. This newly constructed facility is strategically designed to act as a collaborative epicenter for clients, offering them the unique opportunity to test separation equipment under customized conditions. Such an approach ensures that clients can validate the optimal performance of the equipment and make well-informed selections tailored precisely to their specific operational requirements.

Diverse Testing Modules for Industry-Specific Challenges

The pilot testing workshop is a comprehensive setup, integrating five specialized testing modules. Each module is meticulously crafted to tackle distinct industrial challenges, spanning across sectors like mining, drilling, and environmental engineering. This reflects GN Separation's unwavering commitment to delivering end-to-end solutions that cater to the complex and varied demands of material separation.

1. Mining Vibrating Screen Module: Achieving Precision in Mineral Processing

This module is engineered to replicate full-scale production environments, providing a realistic setting for evaluating critical ore processing operations such as classification, dewatering, and desliming. Clients have the flexibility to experiment with different screen configurations and particle size distributions, enabling them to fine-tune their processes for maximum throughput and recovery rates.

2. Drilling Mud Shaker Module: Efficient Mud Management Across Sectors

Specifically designed to meet the needs of the oil, gas, trenchless, and geothermal industries, this module simulates drilling mud recycling systems under dynamic operating conditions. Engineers can rigorously assess screen durability, blinding resistance, and solids control efficiency across a wide range of mud formulations, including water-based, oil-based, and synthetic variants.

3. Decanter Centrifuge Testing Module: Versatile Solid-Liquid Separation Solutions

The Decanter Centrifuge Testing Module is a versatile platform that supports applications across multiple industries. It allows clients to evaluate the performance of centrifugal separation for various processes like sludge dewatering, biomass recovery, and wastewater treatment. With variable-speed drives and adjustable differential speeds, clients can exercise precise control over cake dryness and centrate clarity, ensuring optimal results.

4. Combined Vibrating Screen-Centrifuge Module: Tackling Complex Multi-Stage Processing

For materials that require sequential separation stages, such as drilling cuttings or industrial slurries, this combined module offers an integrated solution. It effectively addresses the challenges posed by wide particle size distributions and variable feed compositions, providing a comprehensive approach to complex material separation.

5. Solid Vacuum Pump Module: Validating Pneumatic Conveying Performance

The solid vacuum pump module is dedicated to evaluating material transfer systems for powders, granules, and slurries. Clients can conduct tests to determine vacuum pump capacities, pipeline diameters, and air-to-material ratios, enabling them to prevent blockages and maintain consistent flow rates for efficient material handling.

Client-Centric Approach and Global Influence

Each testing module is equipped with advanced monitoring capabilities, allowing clients to track key performance indicators such as separation efficiency, energy consumption, and wear rates. The dedicated team of GN engineers provides onsite support throughout the testing process, offering expert guidance and developing predictive maintenance protocols to ensure long-term equipment reliability.

With the launch of its Pilot Testing Workshop, GN Separation solidifies its position as a leading professional provider of industrial separation solutions. This innovative facility empowers clients to navigate technological transitions with confidence and agility, driving progress and efficiency in their respective industries.

- Details

-

Published: 22 August 2025