- Details

-

Published: 12 September 2025

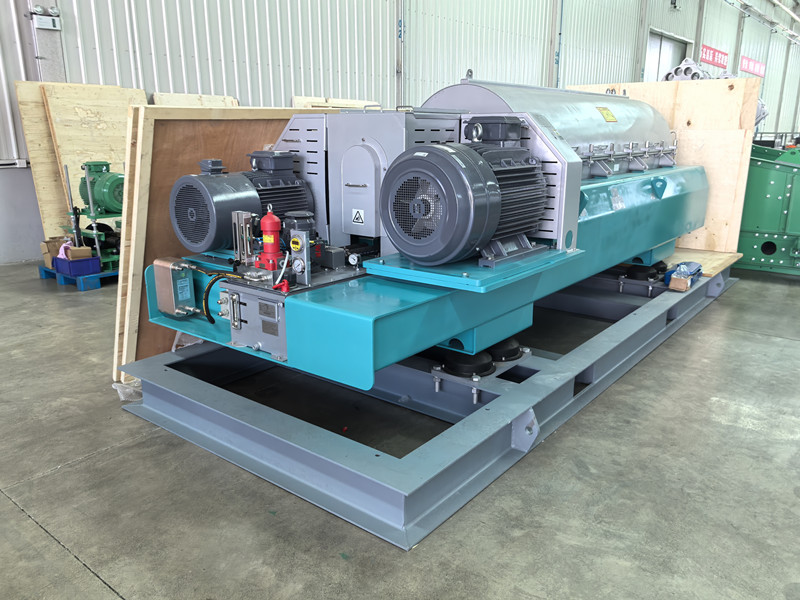

Recently, GN Separation successfully finished the factory acceptance testing of a GNLW654 Decanter Centrifuge. This unit, designed with features that enhance operational flexibility and durability, is now ready to be shipped to a major client in Europe.

Dual-Motor Drive System: Precision Control for Dynamic Operating Conditions

The outstanding performance of the GNLW654 dewatering centrifuge is largely attributed to its dual-motor drive configuration. This design allows operators to precisely adjust both the rotational speed of the main bowl and the differential speed between the bowl and the screw propeller. As a result, separation efficiency can be optimized under various process conditions. Whether dealing with viscous slurries, abrasive tailings, or feeds with fluctuating compositions, the dual-motor system enables quick adaptation to material changes, minimizing downtime and maximizing throughput.

Continuous Lubrication: Ensuring Reliable Operation Under High Pressure

To ensure uninterrupted performance in demanding 24/7 operational settings, the GNLW654 features a fully automated thin-oil lubrication system. Unlike grease-lubricated models, this closed-loop system continuously circulates oil to both main bearings, effectively dissipating heat and preventing premature wear. By maintaining optimal lubrication levels even under extreme loads, the system extends bearing lifespan, reduces maintenance frequency, and lowers lifecycle costs.

Tungsten Carbide Wear Protection: Designed for Longevity

Given the abrasive nature of slurry processing, GN Separation has fitted the GNLW654's rotating assembly with tungsten carbide wear plates and liners in high-contact areas. These hard components are well-known for their resistance to erosion and corrosion, protecting vulnerable parts such as the screw flights and feed zone from degradation. This results in a significant increase in the mean time between failures, with some clients reporting longer service intervals for wear parts.

Synergy with Flocculation Dosing Systems: Enhancing Separation Efficiency

The capabilities of the GNLW654 are further enhanced when used in conjunction with GN Separation's chemical dosing units, offering a comprehensive solution for solids-liquid separation challenges. In wastewater treatment, the centrifuge works alongside polymer dosing systems to improve particle aggregation, facilitating the efficient removal of suspended solids and biological sludge.

In mining applications, this combination is equally transformative. By pre-treating tailings pulp with flocculants, the GNLW654 achieves higher solids capture rates, which is crucial for sustainable tailings management. Recent field trials of GN's tailing dewatering centrifuge at a copper mine in Mexico showed a reduction in the solids content of clarified tailing slurry, significantly decreasing waste disposal.

Global Reach: From Municipal Plants to Mining Industry Leaders

In recent years, GN Separation's decanter centrifuges have gained a strong reputation for reliability across various industries. The GNLW654, with its modular design and scalable capacity, is attracting interest from European municipalities looking to upgrade their aging wastewater infrastructure and mining corporations aiming to modernize their tailings processing.

As the GNLW654 prepares for its transcontinental journey, GN Separation reaffirms its dedication to advancing separation technology. Focusing on durability and process integration, the company is committed to continuing its support for customers in achieving cleaner and more efficient operations.