This October, the global mining sector will gather in Beijing for the 21st China Coal & Mining Expo (CCME 2025), a top-tier event focused on propelling advancements in coal and mineral extraction technologies.

Event Overview

Set to run from October 28 to 31, 2025, at the Capital International Convention and Exhibition Center in Shunyi, Beijing, CCME 2025 is expected to draw a diverse range of exhibitors. These include prominent domestic and international manufacturers, technology suppliers, and industry specialists. Over the course of four days, the exhibition will zero in on sustainable mining practices, automation, and equipment innovation, providing attendees with a gateway to the latest and most effective coal mining solutions.

GN Separation's Participation

GN Separation is among the exhibitors and will be stationed at Booth A4601. The company is set to display a range of equipment aimed at tackling key issues in coal preparation, tailings management, and underground mining operations.

1. Large Flip-Flow Vibrating Screen

The centerpiece of GN Separation's exhibit will be its Large Flip-Flow Vibrating Screen, a groundbreaking screening technology tailored for fine-grained and sticky materials. Traditional vibrating screens often encounter problems like clogging and inefficient separation when handling fine coal, wet ore, or materials rich in clay. GN's flip-flow design, however, breaks through these limitations. By integrating a flexible polyurethane screen surface with a double-mass near-resonance working principle, it prevents screen blinding and pegging, ensuring a steady throughput. In the realm of coal mining, this equipment proves especially valuable for pre-screening raw coal before the washing process, thereby easing the load on subsequent operations.

2. Tailing Dewatering Decanter Centrifuge

Tailings disposal stands as one of the most urgent environmental challenges in the mining industry. GN Separation's Tailing Dewatering Decanter offers an eco-friendly solution. It reduces the water content in mine waste, separating solids from liquids to produce a dry, stackable cake. This not only minimizes land use but also lowers the risk of leachate. In coal preparation plants, the decanter centrifuge facilitates the recycling of process water, cutting down on freshwater consumption. With a capacity of up to 100 cubic meters per hour, it is an ideal choice for mid-to-large-scale operations looking to enhance waste management while adhering to ESG (Environmental, Social, and Governance) standards.

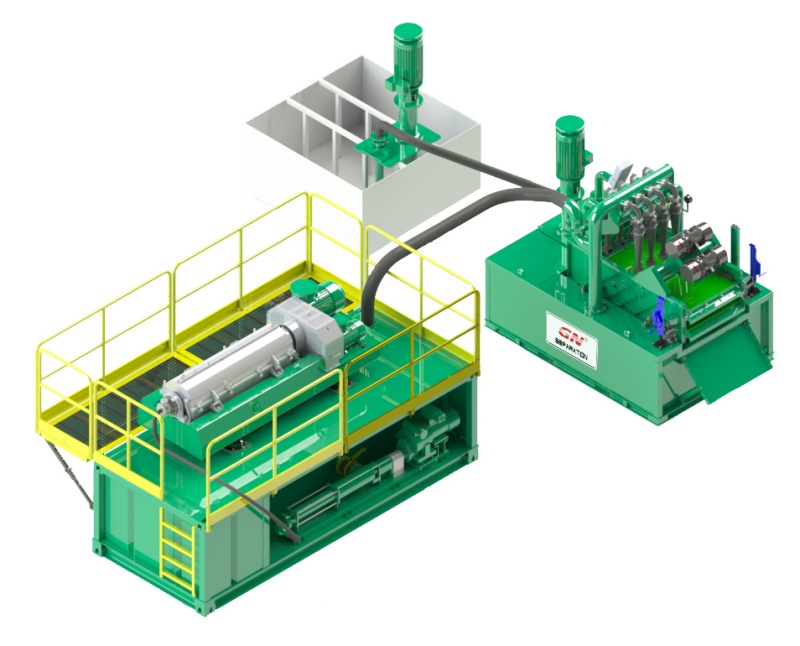

3. Underground Coal Sump Slurry Separation System

Underground mining environments present unique hurdles, such as limited space, water inflow, and the urgent need for efficient slurry handling. GN Separation's Underground Coal Sump Slurry Dewatering System addresses these challenges by integrating a compact decanter centrifuge with a pre-screening module. It treats the muddy water generated during roadway tunneling, coal extraction, and dust suppression. The system first separates coarse solids using a screening cyclone combination unit, and then transfers the slurry to a dewatering centrifuge for fine particle separation. This process eliminates the need for manual sump dredging, ensures smooth mine drainage, and supports safe, efficient, and eco-friendly mining practices. Typically designed in a modular fashion, the system is easy to transport, install, and relocate, enabling mobile use.

GN Separation: Leading the Way to a Sustainable Mining Future

With over ten years of experience in separation technologies, GN Separation has cemented its reputation as a reliable partner for mining companies across the globe. Its participation in CCME 2025 underscores its commitment to innovation and customer-focused design. Visitors to Booth A4601 will have the chance to interact with technical experts, witness live demonstrations, and explore customized solutions tailored to their specific operational requirements. We warmly invite you to visit GN at the expo.

- Details

-

Published: 19 October 2025

GN Separation is pleased to announce our participation in The China Coal & Mining Expo (CCME) 2025, which will be held from October 28 to 31, 2025, at the Capital International Convention and Exhibition Center (Shunyi, Beijing). We sincerely invite all our partners and visitors from the mining and industrial sectors to visit Booth A4601 to explore our advanced solid-liquid separation solutions.

- Details

-

Published: 17 October 2025

In today’s industrial landscape, decanter centrifuges have become indispensable equipment for solid–liquid separation. With continuous operation, sealed construction, and adaptability to a wide range of materials, they offer efficient, reliable, and environmentally friendly performance across multiple industries. From wastewater management to food processing and energy production, decanter centrifuges are playing a vital role in promoting resource recovery and sustainable development.

- Details

-

Published: 11 October 2025

GN Separation proudly announced the successful installation and operation of its renowned linear dewatering screen and big bowl decanter centrifuge at a U.S. engineering slurry treatment plant. Recent operational photos shared by the client vividly demonstrate GN's prowess in crafting customized solutions for intricate industrial demands.

1. Linear Dewatering Screen: Precision in Primary Separation

GN's linear dewatering vibrating screen is a masterpiece of engineering, specifically designed to handle high-volume slurry streams with exceptional efficiency. It utilizes a dual-motor vibrating mechanism to ensure optimal screening performance, even in the most abrasive conditions. This innovative design minimizes the risk of clogging while maximizing throughput. Its compact structure makes installation a breeze, and the modular design of the screen panels allows for flexible replacement, significantly reducing downtime during maintenance.

2. High-Speed Decanter Centrifuge: Advanced Secondary Separation

The decanter centrifuge serves as a perfect complement to the dewatering screen, refining slurry treatment through the power of centrifugal force. Operating at high rotational speeds, it generates centrifugal forces of approximately 3,000g, enabling the separation of fine particles as small as 2–5μm and achieving dry solids content of up to around 75%. The adjustable conveyor speed and pond depth offer a high degree of customization, allowing it to handle a diverse range of feed materials, from clay-rich slurries to chemically treated wastewater. Constructed with robust duplex stainless steel and tungsten carbide tiles, the centrifuge is built to withstand corrosive and abrasive conditions, ensuring a long service life.

Synergistic Application in Slurry Treatment

The integration of GN's dewatering vibrating screen and decanter centrifuge forms a highly efficient two-stage separation process, specifically optimized for engineering slurry treatment. The primary objective of this process is to recover clean water for reuse or safe discharge.

1. Primary Separation: Linear Dewatering Screen

At the initial stage, raw slurry is fed into the dewatering screen. The vibrating motor generates linear motion, causing larger particles to migrate across the screen deck, while water and fines pass through. This crucial step reduces the solid load of the slurry, thereby minimizing wear on downstream equipment.

2. Secondary Separation: Decanter Centrifuge

The effluent from the dewatering screen, which still contains suspended fines, is then pumped into the decanter centrifuge. Inside the rotating bowl, centrifugal force accelerates sedimentation, effectively separating solids from the liquid phase. The clarified water exits through the liquid discharge ports, ready for recycling in various applications such as concrete production or irrigation. Meanwhile, the dewatered solids are transported via the screw conveyor for disposal.

Advantages of the Combined System

Enhanced Water Recovery

The process efficiently recovers a substantial amount of process water, significantly reducing freshwater consumption and the associated compliance risks.

Lower Disposal Costs

By producing drier solids, the system effectively cuts transportation and landfill fees, resulting in substantial cost savings.

Environmental Compliance

The system meets stringent regulations for wastewater discharge, helping clients avoid fines and reputational damage.

GN Separation is a leader in designing and manufacturing mining vibrating screens and decanter centrifuges for a wide range of industries, including oil and gas, mining, environmental engineering, and food processing. With a global presence spanning over 70 countries, the company is widely recognized for its R&D-driven innovations and unwavering commitment to sustainability.

- Details

-

Published: 04 October 2025

In many industries such as mining, wastewater treatment, tunneling, oil & gas, and food processing, the transfer of solids is an important part of operations. GN Separation’s Solids Vacuum Pump (also called a sludge vacuum pump) provides a practical solution for moving powders, slurries, sludge, and other challenging materials.

- Details

-

Published: 30 September 2025

GN Separation has recently finished assembling and packaging a batch of Solids Vacuum Pumps. These pumps, specifically designed for high-efficiency pneumatic conveying, are set to be shipped promptly to a major client in the Middle East. There, they will assume a crucial role in transporting oily sludge, a tough byproduct from oil and gas operations.

How the GN Solids Vacuum Pump Functions: A Pneumatic Powerhouse

The GN Solids Vacuum Pump stands at the core of GN Separation's technological innovations. It is a fully pneumatic device, crafted to handle a wide variety of materials with remarkable adaptability. Traditional mechanical pumps, which depend on rotating parts prone to wear and tear, are outperformed by this system. The GN Solids Vacuum Pump operates through a compressed air-driven mechanism, eliminating the need for electrical power and substantially cutting down on maintenance costs.

The pump's operation is based on a cyclical "suck-and-discharge" process, powered by an external air compressor or gas supply unit. When activated, compressed air enters the pump's air chamber, creating a vacuum that draws in materials—ranging from liquids, slurries, and powders to gravel and fine aggregates—through a suction hose. Once the chamber is full, the airflow direction reverses, expelling the collected material through a discharge pipe.

Typical Applications Across Industries

The versatility of the GN Solids Vacuum Pump has rendered it essential in sectors where efficient and safe material handling is paramount. Here are three prominent applications that are transforming industrial workflows:

1. Environmental Protection: Sludge Pool Cleanup

In wastewater treatment plants and industrial effluent management systems, sedimentation tanks gradually accumulate thick, viscous sludge. Manual dredging of these tanks is not only labor-intensive but also hazardous, often exposing workers to toxic substances. GN's vacuum pump automates this process by suctioning sludge directly from the tank bottoms and transferring it to dewatering systems or disposal sites. Its capacity to handle mixtures with high solid content ensures thorough cleanup while minimizing operational downtime.

2. Mining: Efficient Slurry Transport

Mining operations produce vast quantities of mineral-laden slurry, which needs to be transported from extraction sites to processing plants over considerable distances. Conventional pump systems often face challenges with clogs and erosion caused by coarse particles, leading to frequent breakdowns. GN's solids vacuum pump overcomes these issues by generating sufficient suction force to lift and transport the slurries effectively.

3. Oil & Gas: Oily Sludge Management

The project for the Middle Eastern client underscores the pump's critical role in tackling one of the oil and gas industry's most persistent problems: oily sludge. This waste, composed of hydrocarbons, water, and solid particles, presents significant environmental risks if not disposed of properly. GN's vacuum pump efficiently extracts sludge from storage pits and separators, transferring it to oil sludge treatment systems for oil recovery and safe disposal. Its pneumatic design mitigates ignition risks in explosive atmospheres, adhering to stringent international safety standards.

GN Separation's solid vacuum pump offers a revolutionary approach to transporting industrial materials, merging robust engineering with eco-friendly design. By reducing reliance on fossil fuels and minimizing waste generation, this technology not only aligns with global sustainable development goals but also delivers tangible economic benefits to customers.

- Details

-

Published: 26 September 2025