GN Separation is pleased to announce that it will participate in the Asiawater 2026, one of the most influential water and wastewater industry exhibitions in Southeast Asia.

The exhibition will take place from April 7 to April 9, 2026, at the Kuala Lumpur Convention Centre.

- Details

-

Published: 06 March 2026

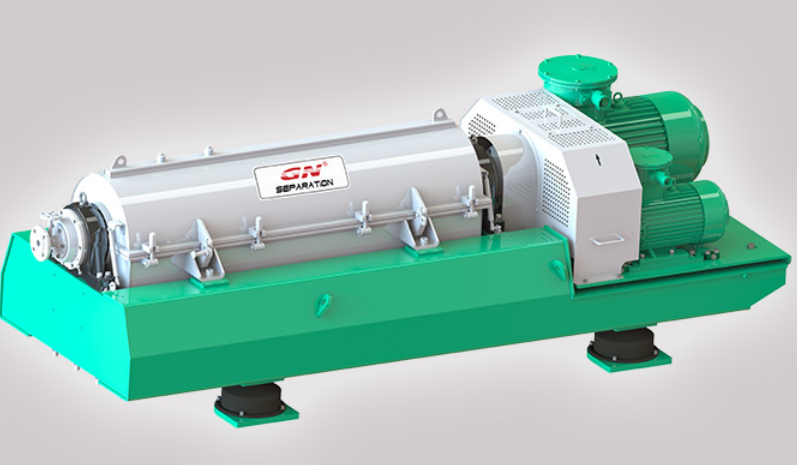

In the context of the continuous and robust growth of the global environmental protection industry, wastewater treatment has emerged as a focal point for both municipal and industrial sectors. The increasingly stringent environmental regulations, growing concerns over water scarcity, and rising demands for water reuse have collectively fueled a strong market need for separation equipment that is highly efficient, reliable, and cost-effective. As industries across the globe strive to achieve their sustainability goals, advanced technologies such as decanter centrifuges play a pivotal role in enhancing wastewater management. Recently, GN Separation successfully delivered a batch of GNLW364 Decanter Centrifuges to an overseas wastewater treatment company, further solidifying our strong foothold in the international environmental market.

Tailored Design for Wastewater Treatment

The GNLW364 Decanter Centrifuge is specifically engineered for the continuous dewatering of sludge and solid-liquid separation in municipal and industrial wastewater treatment plants. Its stable performance, high processing efficiency, and capability for 24-hour continuous operation make it an ideal solution for modern wastewater treatment facilities. Compared to traditional separation equipment, this decanter centrifuge significantly reduces labor requirements, enhances automation levels, and ensures consistent performance. These advantages enable wastewater treatment plants to achieve operational efficiency while complying with stringent environmental standards.

Compact and Space-Saving Design

One of the most prominent features of the GNLW364 model is its compact and space-saving design. The dual motors are strategically arranged at one end, allowing the centrifuge to occupy a smaller footprint. This is particularly advantageous for plants with limited installation space. Additionally, the compact layout simplifies the installation, operation, and maintenance processes, thereby reducing both time and costs for operators.

Unparalleled Durability and Reliability

Durability and reliability are the hallmarks of the GNLW364 model. The bowl and critical rotating components are crafted from high-grade duplex stainless steel, providing exceptional corrosion resistance and ensuring a long service life even under harsh wastewater conditions. The screw conveyor is meticulously designed to optimize solids transport and enhance dewatering efficiency, resulting in clearer liquid discharge and drier solids. Wear-resistant protection on key parts minimizes maintenance frequency and extends the equipment's lifespan. Furthermore, premium bearings and optional automatic lubrication systems guarantee smooth and reliable long-term operation.

Advanced Safety and Operational Monitoring

Safety and operational monitoring are integral aspects of the GNLW364 Decanter Centrifuge. It is equipped with a comprehensive monitoring and alarm system that tracks all key operating parameters in real-time. In the event of abnormal conditions, automatic protection functions are immediately activated to minimize downtime and safeguard personnel and equipment. These features provide wastewater treatment plants with the confidence to operate at high productivity levels while maintaining optimal safety standards.

GN's Commitment to Excellence

The successful delivery of this batch of GNLW364 Decanter Centrifuges underscores GN's unwavering commitment to providing reliable, efficient, and environmentally responsible solid-liquid separation solutions to our global customers. By integrating advanced technology, durable construction, and user-friendly design, GN empowers wastewater treatment facilities to enhance their performance, reduce operational costs, and contribute to sustainable water management. Moving forward, we will continue to support the environmental protection and wastewater treatment industries worldwide, promoting cleaner water and a healthier, more sustainable future for communities across the globe.

- Details

-

Published: 01 March 2026

GN Solids Control is thrilled to announce a major supply to the Horizontal Directional Drilling (HDD) industry: three complete GNMS - 1000 Mud Recycling Systems and forty high - wear - resistant slurry pumps have been successfully dispatched to a major client. This large - scale order clearly demonstrates our ability to provide comprehensive, integrated solutions that significantly boost operational efficiency and reliability in trenchless drilling projects.

Three Sets of GNMS - 1000 Mud Recycling Systems

Each GNMS - 1000 Mud Recycling System is a fully - integrated, self - sufficient unit crafted for maximum efficiency. It incorporates a shale shaker, mud cleaner, mud tank, slurry pumps, and mud agitators into one cohesive package. This all - inclusive design not only offers thorough drilling fluid purification and mixing but also provides sufficient storage capacity. It is specifically engineered to handle the rigorous demands of complex and high - volume HDD operations, ensuring optimal fluid performance throughout the entire project.

Forty Units of Submersible Slurry Pumps

These forty slurry pumps, which complement the mud systems, are constructed to withstand harsh conditions. Equipped with high - chrome alloy pump casings and impellers, they are designed for excellent abrasion resistance and an extended service life. Their sturdy, low - maintenance construction makes them perfect for the continuous transfer of drilling fluid from mud pits in HDD applications. This helps prevent costly disruptions and ensures smooth project execution.

This shipment is a prime example of GN Solids Control's dedication to delivering end - to - end drilling fluid management solutions. Our services cover everything from precise solids separation and cleaning to reliable fluid transfer. By providing such integrated packages, we assist our clients in reducing overall operational costs, minimizing downtime, and greatly enhancing project reliability.

We take great pride in contributing to the success of major HDD projects around the globe and are committed to continuously developing equipment that can meet the ever - changing challenges of the trenchless technology industry.

- Details

-

Published: 22 February 2026

In the midst of the swift transformation of the global economy and technological landscape, GN has consistently navigated forward through innovation and quality, solidifying its global strategic footprint and maintaining its leadership in the development of solid-liquid separation technology and equipment. By 2025, with firm steps, we have made remarkable strides across global markets and various core industries, embarking on a new journey with our partners, "Staying Together" to "Power the Future."

1. A Global Network, Harnessing Worldwide Talent

GN has established a significant strategic presence worldwide. Within China, we have five key strategic locations: our headquarters in Yutian, along with branches in Langfang, Tangshan, Tianjin, and Shanghai. Our modern 80,000-square-meter headquarters in Yutian, Tangshan, serves as the cornerstone for over 350 GN team members and the bedrock of our confidence in serving the global market. Langfang Plant No. 1, a testament to a decade of dedication and memories, completed its mission successfully in 2023. GN Plant No. 2, our screen manufacturing hub and domestic office, now carries the torch forward into a promising future. Overseas, our three subsidiaries—GN America, GN Australia, and GN Middle East—are deeply integrated into local markets, providing efficient and convenient services to international customers.

nianhui0202

2. Dual Brands, Soaring to New Heights Together

Guided by our dual-brand strategy of "GN Solids Control" and "GN Separation," we operate like the two powerful wings of an eagle, synergizing across three key application industries—oil & gas drilling, wastewater treatment, and mining separation—to co-author a new chapter in GN's development.

nianhui0203

3. 2025 Key Projects: A Trail of Successes

For GN Solids Control Projects, we have built a solid foundation and witnessed a steady rise in performance: We delivered over 10 sets of solids control systems in bulk to oil drilling companies; rig systems such as the 3000HP, 1500HP, and 750HP workover rigs were successfully sold to clients in Asia, Europe, and domestic oilfields, with successful on-site installation and commissioning. Concurrently, we successfully penetrated the high-end market, exporting over 20 sets of HDD mud systems to Europe and North America in bulk. Hydrovac mud systems and slurry separation systems for pipe jacking projects were also deployed in the USA, Australia, and other regions. Our technological excellence has bolstered our reputation: 2 sets of advanced oil sludge treatment systems were delivered to Kazakhstan, and 16 sets of drilling fluid centrifuges were reordered by a North African client, showcasing profound customer trust.

In the GN Separation Projects sector, we have advanced with determination, achieving new milestones: The major delivery of over 20 units of 760mm large-bowl centrifuges solidified our leading position in high-end mining separation. The mining screen product line also excelled, receiving bulk orders from domestic and international clients and being successfully applied in projects such as Inner Mongolia gasification slag treatment and ilmenite grinding classification. Moreover, our decanter centrifuges are expanding their reach across separation industries like environmental protection, chemical, and food processing. Applications in sludge dewatering, chemical crystal separation, and olive oil waste treatment are thriving, demonstrating their exceptional adaptability across industries.

4. Stay Together, Power the Future

Our business remains centered on two core products—vibrating screens and centrifuges—deeply serving three pillar industries: oil & gas drilling, wastewater treatment, and mineral processing. From mud purification for oil exploration to sludge treatment for a greener environment, and to the fine separation of mineral resources, GN equipment is integral to key project sites worldwide.

nianhui0206

"Stay Together, Power the Future"—this is not only our summary for 2025 but also our commitment to the future. It emboldens us to explore and drives us to move forward with determination. The future is now. GN sincerely invites global technical experts and sales pioneers to join us, to walk hand in hand, define new industry standards together, and forge a brilliant new future side by side.

- Details

-

Published: 15 February 2026

As environmental protection gains prominence globally, alongside a rising emphasis on water reuse and sustainable municipal infrastructure development, there's a burgeoning worldwide demand for efficient and cost-effective sewage treatment solutions. Recently, our company successfully delivered a comprehensive sewage sludge treatment system to an overseas client. This system comprises a Slant Plate Clarifier, a Screw Press Dewatering Machine, and an integrated Chemical Dosing Unit, showcasing the growing international acceptance of compact and energy-efficient sludge treatment technologies.

In numerous municipal and industrial wastewater treatment facilities, front-end sludge concentration is pivotal for enhancing overall treatment efficiency. The Slant Plate Clarifier, also referred to as an inclined plate clarifier, serves as a widely adopted pre-concentration unit to elevate sludge concentration prior to dewatering. Compared to traditional settling tanks, slant plate clarifiers occupy a significantly smaller area while offering a much larger effective settling surface. This characteristic renders them especially suitable for overseas projects constrained by limited land availability or high civil construction expenses.

The Slant Plate Clarifier is a liquid-solid separation apparatus designed to boost sedimentation efficiency. When the flocculated sewage stream enters the clarifier's inlet trough, it ascends between a series of inclined plates. Under the influence of gravity, solid particles settle onto the plate surfaces and slide down into the sludge collection hopper. Simultaneously, clarified effluent rises through orifice holes and exits from the unit's top. This design substantially shortens the settling distance and enhances separation performance, even under fluctuating flow conditions.

From a market standpoint, slant plate clarifiers are gaining increasing favor in municipal sewage treatment, industrial wastewater pretreatment, and sludge thickening applications. They are more economical than decanter centrifuges, consume less energy, and are simpler to operate and maintain. These benefits make slant plate clarifiers an appealing option for developing markets and projects aiming to cut operational costs without sacrificing treatment efficiency.

The Dewatering Screw Press, as the central sludge dewatering equipment in this system, plays a crucial role in reducing sludge volume and achieving consistent dry solids content. Operating continuously at a low rotational speed, the screw press ensures low power consumption, minimal noise, and reliable long-term performance. Its clog-free design is particularly well-suited for sewage sludge with high organic content and variable characteristics, which are common challenges in overseas wastewater treatment projects.

To guarantee effective flocculation and stable dewatering performance, the system incorporates a Chemical Dosing Unit for flocculant preparation and dosing. This unit enables precise polymer solution preparation and controlled dosing, optimizing sludge conditioning before both thickening and dewatering stages. This integrated approach enhances sludge cake dryness and reduces overall chemical usage.

This overseas project exemplifies how the integration of a Slant Plate Clarifier, Screw Press, and Chemical Dosing Unit can create a compact, efficient, and cost-effective sewage sludge treatment solution. With the global demand for sustainable wastewater treatment on the rise, such integrated systems are poised to assume an increasingly significant role in municipal and industrial sewage treatment plants worldwide.

- Details

-

Published: 05 February 2026

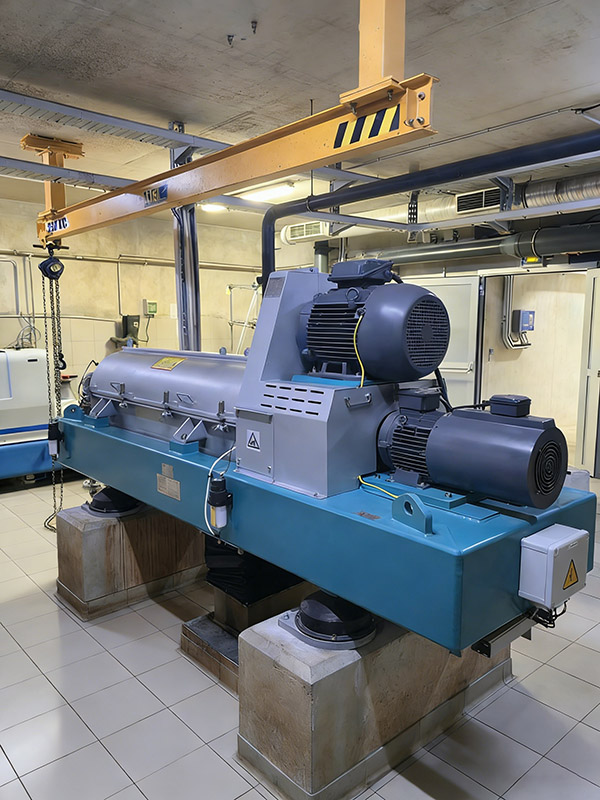

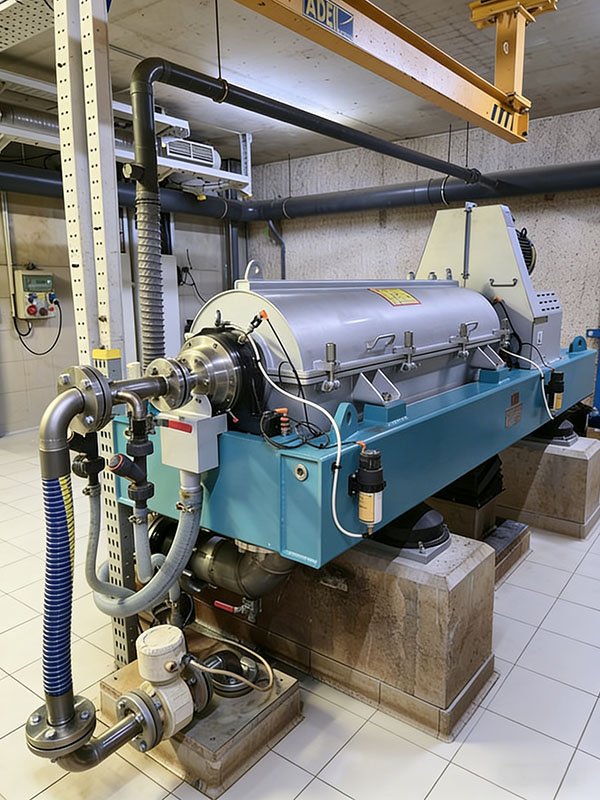

GN Separation, a leading Chinese manufacturer specializing in solid-liquid separation equipment, achieved a significant milestone by successfully installing and commissioning its decanter centrifuge at a sewage treatment plant (STP) in France. With the invaluable assistance of its local partner, the project proceeded without a hitch, and the centrifuge is now running smoothly, fully meeting all performance benchmarks. This successful commissioning has garnered glowing praise from the end user, who commended the equipment's reliability and outstanding operational performance.

This project underscores GN Separation's unwavering commitment to delivering cutting-edge wastewater treatment solutions on a global scale. By working hand-in-hand with its local partner in France, GN Separation ensured that every stage of the installation process, from mechanical assembly to system calibration, adhered to the most stringent standards. The partner's professional guidance in maintenance and installation was instrumental in seamlessly integrating the decanter centrifuge into the plant's existing operations.

The project serves as a prime example of the effective utilization of GN's dewatering decanter centrifuge in municipal wastewater treatment processes, especially in sludge dewatering operations. Thanks to the support of the local French partner, the plant can now count on stable installation, operation, and maintenance services, guaranteeing consistent performance over the long haul. This collaboration highlights GN Separation's dedication to providing practical, reliable solutions and comprehensive technical support to wastewater treatment facilities throughout Europe.

GN Separation's decanter centrifuge is engineered for optimal sludge dewatering efficiency, high throughput capacity, and minimal maintenance requirements. Its robust construction ensures stable operation even in the most challenging conditions, making it an ideal choice for both municipal and industrial wastewater treatment facilities. The successful deployment of this equipment in France stands as a testament to its versatility and GN Separation's ability to tailor solutions to meet the unique needs of different regions.

With the completion of this project, GN Separation continues to solidify its presence in Europe, proving that strategic partnerships can facilitate the efficient and effective implementation of advanced engineering solutions. The company remains steadfast in its pursuit of innovation, operational excellence, and providing end users with sustainable solutions for sludge management and wastewater treatment.

- Details

-

Published: 01 February 2026