- Details

-

Published: 12 February 2025

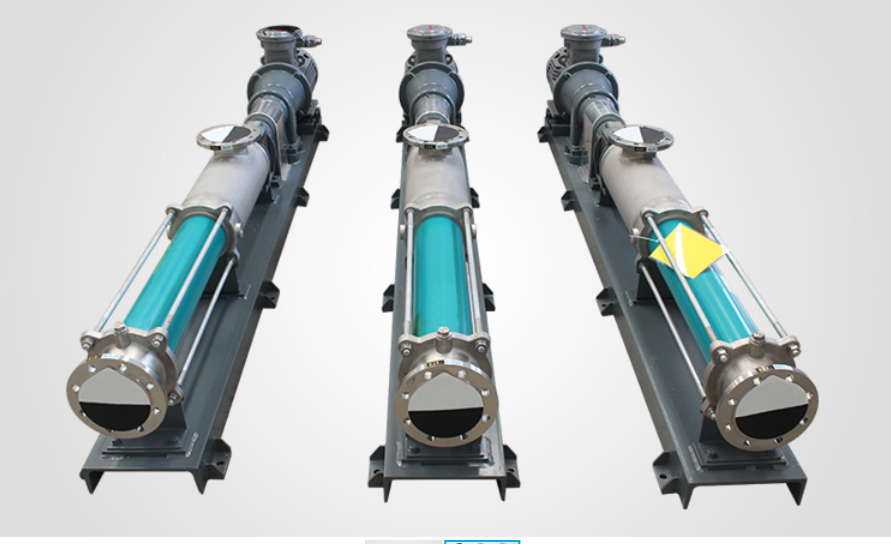

At GN Separation, we understand the importance of reliable and efficient equipment for demanding applications. Our GNG Series Progressive Cavity Pump, also known as a single screw pump, is designed to provide consistent performance in a variety of industries, particularly when feeding decanter centrifuges. This pump combines strength, durability, and reliability to ensure optimal operation over the long term.

What is the GNG Series Progressive Cavity Pump?

The GNG Series Progressive Cavity Pump consists of a helical rotor turning inside a helical stator. As the rotor moves, it creates a honeycomb structure that spirals along the pump's axis, transferring material from the intake to the discharge without altering its shape or volume. This unique design ensures that the pump moves even the most challenging materials without degrading the product, making it ideal for a range of applications, particularly in sludge transportation and dosing.

Key Features and Advantages

-

Robust Design for Durability: The pump’s body and transmission parts are built to withstand maximum pressure loads of 6 bar. Whether for industrial sludge transfer or continuous dosing, this pump delivers strong, durable, and safe performance.

-

Long-Term Operation: The GNG Series is designed for stable, unmanned operation over extended periods. It’s an ideal solution for industries that require equipment capable of handling demanding tasks without the need for frequent maintenance.

-

Versatile Materials Handling: The rotor and stator can be customized to meet the needs of specific applications. Depending on the material being handled, the rotor can be made of stainless steel or hard alloy, offering enhanced resistance to wear and corrosion.

-

Efficient Flow Control: The stator of the pump is firmly integrated with the outer casing, ensuring a seamless, leak-proof operation. It’s made from high-quality materials like SBBPF, ensuring a long service life of over 10,000 hours under normal working conditions.

-

Compact and Integrated Design: The pump features a compact gear reducer that is seamlessly integrated with the motor, which can be tailored for a wide range of power supplies (380V/460V) and frequencies (10-60Hz). This versatility allows the pump to be used in various industrial environments.

GNG Series Progressive Cavity Pump Specifications

The GNG Series pumps come in various models, designed to suit different flow rates and pressure requirements. Below is a snapshot of the key specifications:

| Model | Flow (m³/h) | Pressure (Mpa) | Motor (Kw) | Max Speed (RPM) | Inlet (Inch) | Outlet (Inch) | Weight (Kg) | Dimension (L×W×H) |

|---|---|---|---|---|---|---|---|---|

| GNG10-040C | 10 (44 GPM) | 0.3 | 4 | 244 | 3 | 3 | 245 | 2245×320×550 |

| GNG20-055C | 20 (88 GPM) | 0.55 | 5.5 | 210 | 3 | 3 | 323 | 2450×340×562 |

| GNG30-075C | 30 (132 GPM) | 0.75 | 7.5 | 258 | 4 | 4 | 386 | 2761×370×600 |

| GNG40-110C | 40 (176 GPM) | 1.1 | 11 | 252 | 5 | 5 | 454 | 3270×370×665 |

| GNG50-110C | 50 (220 GPM) | 1.1 | 11 | 273 | 5 | 5 | 608 | 3790×400×782 |

| GNG60-150C | 60 (264 GPM) | 1.5 | 15 | 225 | 5 | 5 | 649 | 3322×550×740 |

| GNG70-220C | 70 (308 GPM) | 2.2 | 22 | 230 | 6 | 6 | 875 | 3740×420×785 |

| GNG80-220C | 80 (352 GPM) | 2.2 | 22 | 283 | 6 | 6 | 875 | 3740×420×785 |

| GNG90-220C | 90 (396 GPM) | 2.2 | 22 | 205 | 6 | 6 | 875 | 3740×420×785 |

Note: Specifications are for reference and may vary depending on specific application requirements.

Applications of the GNG Series Progressive Cavity Pump

The GNG Series Progressive Cavity Pump is versatile and suitable for various industries, including:

- Chemical Industry: Handling polymers, sizing, resins, hardeners, acids, oils, and water-based paints.

- Mining Industry: Transporting slurries, explosive preparations, coloring agents, and miscellaneous agents.

- Paper Industry: Handling coating colors, dyes, starch, kaolin, talc, bentonite, and other materials.

- Meat Industry: Transporting pet food, fatty products, oils (such as tallow, lard, palm, olive), and enzymes.

- Sugar Industry: Handling molasses, glucose, syrup, starch, honey, and liquor.

- Beverage Industry: Transporting juices, syrups, additives, wine, beer, and other ingredients.

Why Choose the GNG Series Progressive Cavity Pump?

The GNG Series Progressive Cavity Pump by GN Separation is engineered for high-performance, reliability, and versatility. Whether you are looking for a pump to feed your decanter centrifuge or need a solution for your industrial fluid handling requirements, the GNG Series ensures efficient operation and long-lasting durability.

For more information on how the GNG Series Progressive Cavity Pump can enhance your operations, contact GN Separation today. We look forward to providing you with the best solutions for your needs.