- Details

-

Published: 10 January 2025

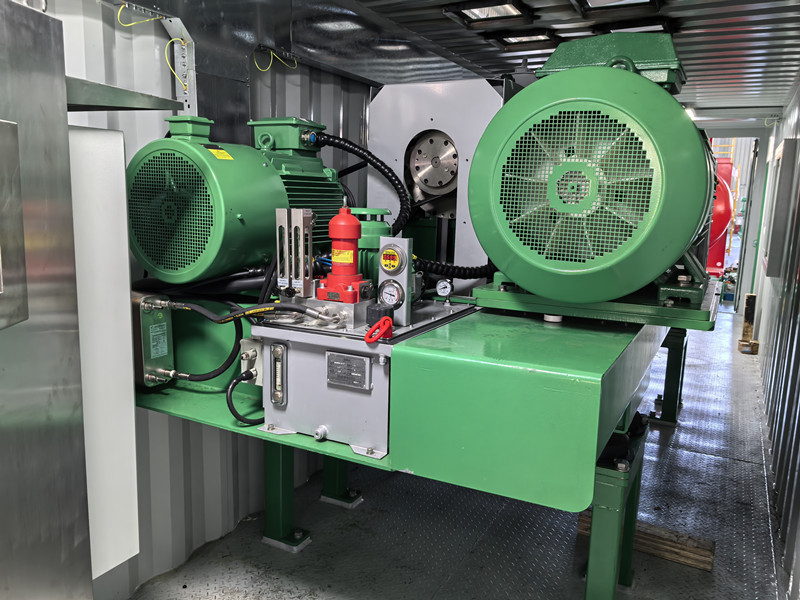

GN Containerized Sludge Dewatering Package for Soil Remediation, Packaged neatly within a standard 40ft container, the system boasts a comprehensive array of equipment tailored for exceptional mobility, straightforward installation, and robust functionality. At its core, the GNLW654-VFD sludge dewatering centrifuge, a powerhouse supplied by GN Separation and specifically tailored for this demanding application, stands out.

The GNLW654-VFD decanter centrifuge is furnished with a Variable Frequency Drive (VFD) control cabinet, a feature that offers operators unparalleled flexibility in adjusting the operational settings of the primary and secondary motors, feed pump, and polymer dosing pump. This capability allows for precise tuning of the system to accommodate varying feedstock attributes and optimize treatment efficiency, ultimately enhancing the quality of the dewatered sludge (or mud cake) while minimizing water content.

Acknowledging the severe abrasiveness of oil-tainted soil sludge, GN Separation has incorporated tungsten carbide plates and sleeves within the centrifuge's screw conveyor and slag discharge port. This strategic incorporation of wear-resistant materials not only safeguards vital components from premature wear and tear but also prolongs the overall lifespan of the equipment, thereby mitigating long-term maintenance expenses and fostering operational consistency. Complementing the centrifuge are a feed pump and dosing pump sourced from Netzsch, a reputable German manufacturer renowned for its dependable and high-performance industrial pumps. These components, integral to the system's seamless operation, guarantee precise and consistent delivery of both the sludge feed and flocculant chemicals crucial for enhancing solid-liquid separation.

The screw conveyor, another pivotal component, has been meticulously designed based on the system's intended throughput and the on-site configuration. This customized design not only facilitates smooth integration into the containerized setup but also ensures straightforward installation and user-friendly operation, which are crucial in remote and often logistically challenging environments akin to those in the Middle East.