- Details

-

Published: 17 May 2024

During the dredging of rivers and lakes, the accumulation of various forms of debris and silt is inevitable. The separation of dredged waste and sludge demands sophisticated classification and separation equipment. At GN Separation, we offer comprehensive solid-liquid separation solutions tailored to this exacting task.

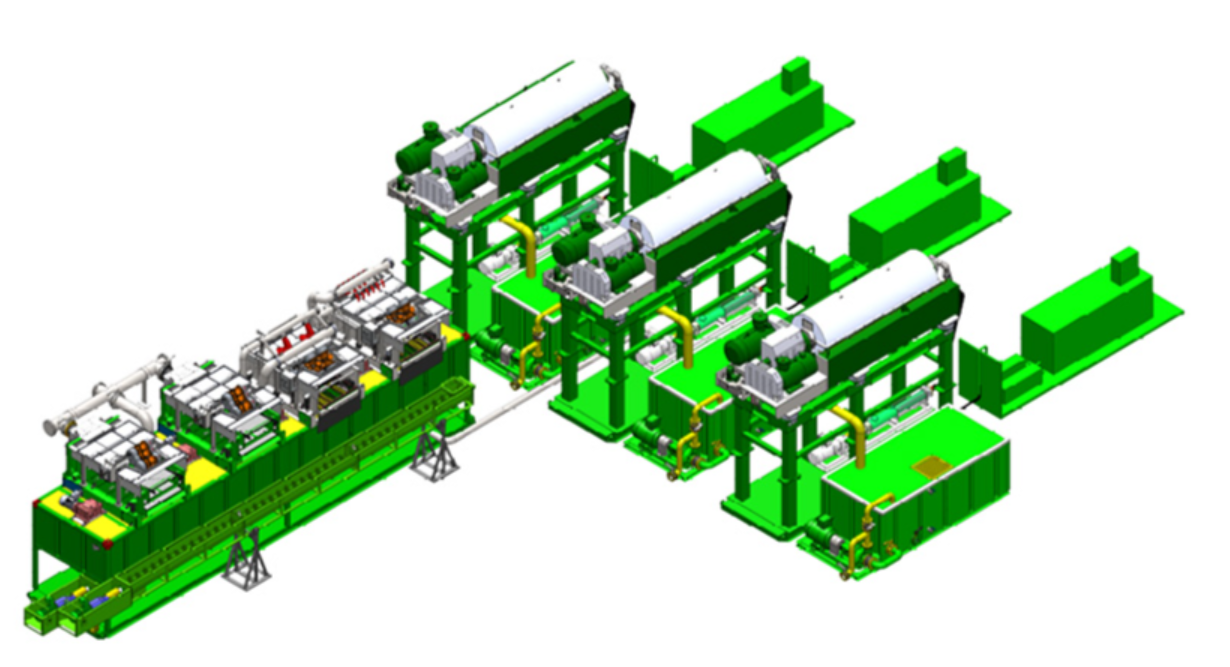

Our turnkey solutions encompass a range of essential equipment, including:

- Garbage Coarse Shaker

- Gravel Fine Shaker

- Desander

- Desilter

- Horizontal Dewatering Centrifuge or Dewatering Screw Press

- Filter Press

These critical components play a pivotal role in the effective separation of solids and liquids during dredging operations. The separated solids find application as construction materials, while the clarified water can be safely returned to the river or lake ecosystem.

GN Dredge Sludge Dewatering Equipment is engineered to meet diverse treatment capacity requirements, with standard systems available in capacities ranging from 120m3/h (500gmp) to 960m3/h (4000GPM). Moreover, we offer customized solutions to address specific working conditions and operational demands.

Key Features of GN Dredge Sludge Dewatering Equipment:

- Customized Turnkey Solutions: Our integrated system encompasses design, manufacturing, assembly, debugging, and comprehensive after-sales support.

- Modular and Integrated Design: Compact footprint and easy transportation ensure operational efficiency and convenience.

- Five-Stage Separation Treatment: Our equipment facilitates seamless separation and drying of solids, ensuring optimal performance and efficiency.

Let's delve into the functionality of our equipment and their respective features:

- Garbage Coarse Screen: Removes debris and bulk solids from dredged sludge, including grass, roots, leaves, cans, plastics, rags, and bottles.

- Gravel Fine Shaker: Utilized for screening when there is minimal garbage and debris, this shaker segregates solid materials of 2mm and 0.5mm sizes, with particles smaller than 0.5mm collected in a separate compartment for subsequent extraction.

- Desander: Removes solid particles larger than 50 microns from the slurry, ensuring efficient separation and processing.

- Desilter: Further refines the slurry by removing particles larger than 20 microns, enhancing the quality of the separated solids and liquids.

- Fine Sludge Dewatering: Processes liquid containing fine sludge particles less than 20 microns, ensuring optimal dewatering and solid-liquid separation.

As a leading manufacturer of integrated Dredge Sludge Dewatering Equipment, GN Separation offers customized solutions tailored to meet the unique requirements of our clients. We are committed to optimizing the treatment of river dredging sludge, enhancing efficiency, and reducing operational costs.

For further inquiries and personalized consultation, please contact us. GN Separation: Your Partner in Advanced Environmental Solutions.