Recently, GN Solids Control launched the new products: ViST Vacuum Shale Shaker Screen Technology. ViST is Vacuum Screen Technology which is to work with shale shaker to reduce drilling waste and recovery usable drilling fluids. ViST technology is was a pending patent design developed by GN Solids Control from June, 2017. Before launching to the market, GN Solids Control took factory test and jobsites test to ensure its performance. It proved to be very efficient for recycling drilling fluids.

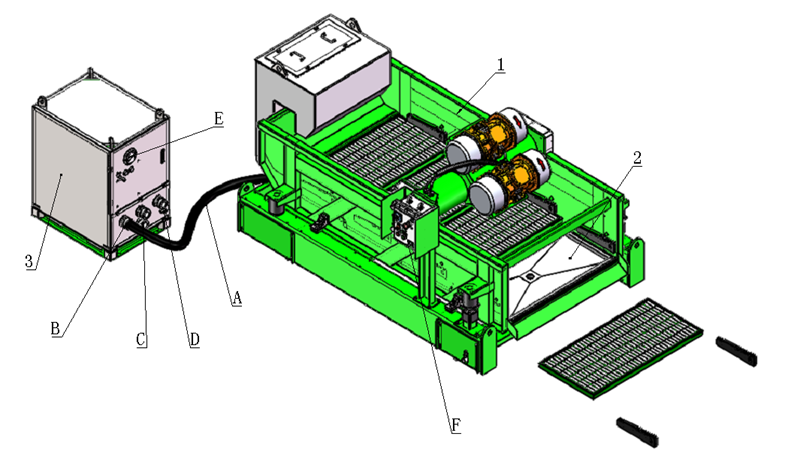

The ViST Pan is installed under the last screen or mounted externally. And a suction hose is connected to ViST vacuum unit. The compressed air from air compressor or the rig air supply is required to create suction on the last screen surface, pulling additional fluid off the cuttings. It can reduce the liquid on the drilling cuttings by 30-50%. GN ViST Vacuum Shale Shaker Screen Technology can suits for different shale shaker models, and a set of ViST Vacuum Shale Shaker Screen unit can cover 2 or 3 shale shakers.

The ViST Vacuum Shale Shaker Screen Technology can be used under shale shaker screens to further drying the cuttings, and recovery more usable drilling fluids. It can be used as a replacement of High G drying shaker. Compared with High G drying shale shaker, the ViST Vacuum Shale Shaker Screen Technology only consume air, there is no electrical parts. In this case, the ViST Vacuum Shale Shaker Screen Technology is a perfect choice for offshore drilling and for hazardous areas. And there is no shaker screen consumption. The operation cost is low.

GN Solids Control developed this technology pushed by some clients. They have the request for projects, but they cannot buy it in the market. GN Solids Control owns his own Research and Development department (R&D). Till now GN Solids Control developed over 20 patents, which are already approved. Some new patent application is under process. That is the reason clients pushed GN to do the research, They believed that GN Solids Control are capacity to do it. And GN did it.

- Details

-

Published: 14 July 2018