In nowadays, a complete oil and gas drilling rig should be equipped at least 2 mud systems: One called solids control system for drilling fluids treatment; another system called the pitless mud system for drill cuttings treatment.

Many clients are wondering, if the pitless mud system for drill cuttings system can replace the shaker tank system or not?

Firstly, we have a draft idea about the 2 mud systems.

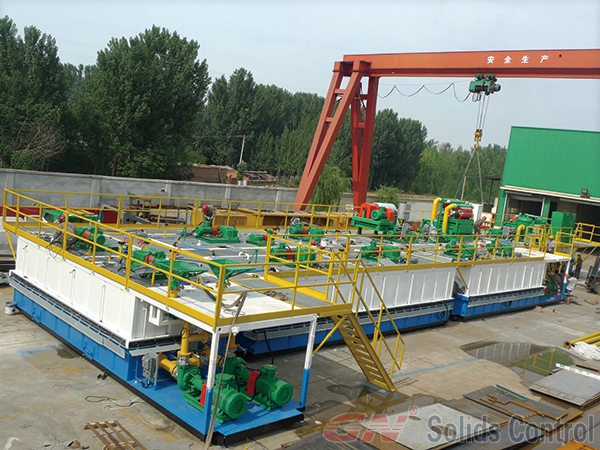

Solids Control system for drilling fluids treatment

Complete solids control system can be composed of 4-stage solids control equipment or 5 stage solids control separation process.

The 1rst stage solids control equipment: shale shaker. It is used to remove the coarse particles from the drilling fluids.

The 2nd stage solids control equipment: Desander, it utilizes 10’’ hydrocyclone cones to remove particles above 47 microns.

The 3rd stage solids control equipment: Desilter, it utilizes 4’’ hydrocyclone cones to remove particles above 27 microns.

The 4th stage solids separation equipment: Decanter centrifuge. It utilizes centrifugal force to remove the fine solids to 2 ~ 5 micron. Middle speed decanter centrifuge is normally used this stage to recovery the barite.

The 4 stages solids control equipment composed of 4 stage separation. Another separation is for vacuum degasser. It is used after shale shaker and before desander desilter.

Clients chose the suitable separation machine per rig condition.

As the mud pit is forbidden in China at the rig site, pitless mud system for drill cuttings treatment are more and more equiped.

1) High G drying shaker, it is normally used to treat water base drill cuttings.

2) Vertical cuttings dryer. It is used to treat oil base drill cuttings.

3) High speed decanter centrifuge will be used after high G drying shaker or vertical cuttings dryer to separate the fine solids

4) Dewatering unit. If there are many ultra fine solids cannot be removed by centrifuge directly. Dewatering unit for chemical dosing will be used.

- Details

-

Published: 02 February 2016