Decanter centrifuge is an important and relative cost high equipment in solids control and drilling waste management equipment. It has an important role on the total system performance. There are so many companies announced for decanter centrifuge manufacturing, especially in China. But do you know how to choose the right one for your drilling waste management project?

As the first China solids control manufacturer who have warehouse in Houston, GN Solids Control give suggestions as below:

1) Check the parameters: To check if the offered centrifuge can meet your request.

2) Check the company’s project list, to make sure they have experience on your field. If you are searching for a centrifuge for drilling cuttings treatment, companies who make centrifuge for pharmaceuticals industry, food industry or solids control should not be suitable. If possible, to talk with the people who used their equipment or to check their jobsite.

3) To check the centrifuge material: For drilling waste management, centrifuge materials should be the highest ranking. It should be very strong and good performance for anti-abrasive.

Bowl material: Duplex Stainless Steel 2205 by centrifugal casting is the best. Derrick centrifuge and Swaco centrifuge made by it. It is excellent and reliable. SS316L is the second option. While SS304 and SS302 not recommended.

4) Screw protection: best option is interchangeable Tungsten Carbide Tiles. Second option is ceramic tiles if your budget is very tight, or just want a cheaper one. Hard surface welding for screw project is not recommended.

In the first year or half year, there maybe not much difference, but after 1 year, the hard surface welding will be worn out. It is difficult for maintenance, and you have to make balance again after welding repair. But the interchangeable tiles, you only need to remove the broken one and change it with a new one.

5) To check the companies’ facility and capability. Centrifuge manufacturing have a high standard request on manufacturer’s capability. It you intend to order from a company, it is better you pay a visit to their company, to check their workshop, see which material they use, how they make, which kind of processing machine they have. CNC machine and Five-face processing machine, dynamic balance machine is the necessary for centrifuge processing.

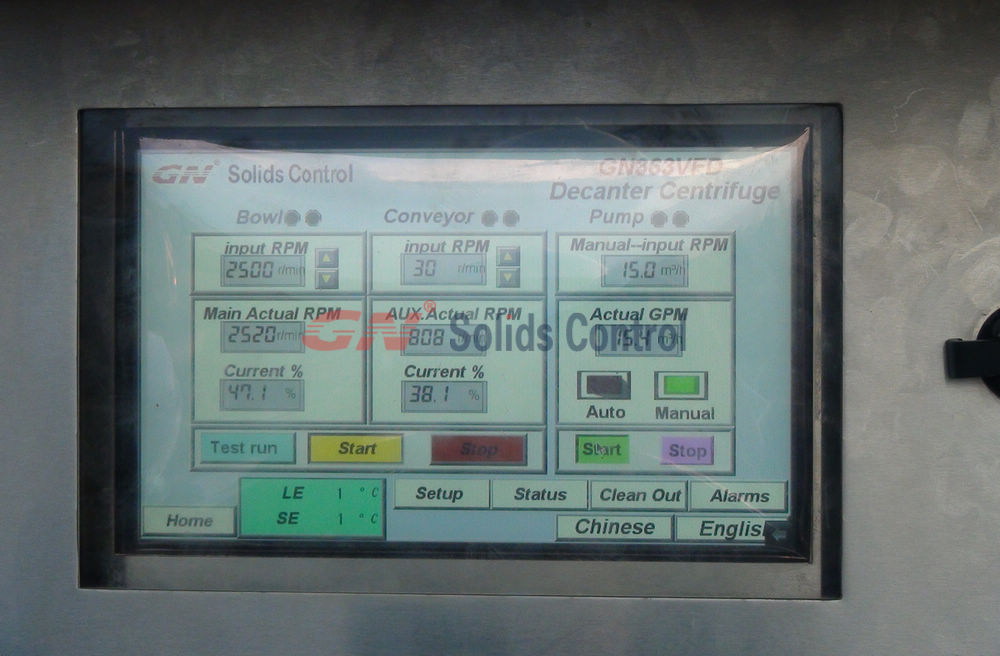

6) VFD Control panel: Possitive pressurized VFD panel with self-cooling is necessary. Flameproof cannot cool down and cannot exactly meet the EX standard. 3 VFD for main drive motor, back drive motor and feeding pump also the best. If there is PLC for smart control, perfect.

7) To check the price: The lowest price surely can be considered. If the price is even much lower than the market average, where they get benefits? Surely the quality cannot be good.

8) To check besides decanter centrifuge, what other equipment they can make for drilling waste management, like high G dryer shaker, screw conveyer, dewatering unit... If they can meet all above, and they can offer you complete solution on drilling cuttings treatment.

If there is a company can meet all of them, then you can consider. If you have any other questions on solids control equipment or drilling waste management, welcome you contact GN Solids Control freely.

- Details

-

Published: 01 November 2014