GN VFD centrifuge is made and designed for mud solids control and drilling waste management.

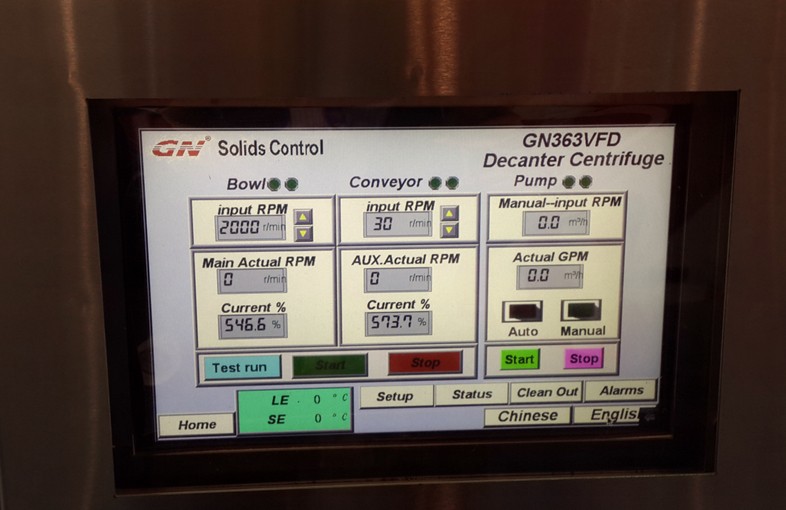

There are 4 parameters can be changed on GN VFD Decanter centrifuge:

1) Bowl speed: More speed, fluids more clean, and accordingly, solids more dryer

2) Conveyer speed: More conveyer speed, the centrifuge push material more fast, means shorter time for separation, more solids in fluids

3) Fluids height at centrifuge big end (the motor end): Now it is already the largest depth. The higher the fluids level, more clean of the fluids.

|

|

|

4) Pump flow: according to different treating material and different performance customer want, capacity different.

Centrifuge operator can follow below steps to find out the most suitable bowl speed, conveyer speed and pump feeding flow for decanter centrifuge in specified jobsite:

Step 1 find out the most suitable bowl speed of VFD decanter centrifuge:

Fixed the conveyor speed, like 30rpm, fix the pump flow, e.g.: 10m3/h: then increase bowl speed more and more. For more speed, the fluids phase from centrifuge will be more clean. So job site operator can try from 2500 / 2800/ 3000/3200 rpm. After 10min around normal running, take sample for each speed.

Compare the different samples to find out the best bowl speed.

Step 2 find out the best centrifuge conveyor speed:

Fix the bow speed as the same with step 1 found out, fixed the same pump flow, 10m3/h. Change conveyer speed from 23rpm, increase it more and more. For every conveyer speed, after 10min, take sample.

Compare different samples and find out the most suitable centrifuge conveyor speed for the jobsite.

|

|

Step 3: find out the biggest pump flow with best performance for the centrifuge in specified jobsite:

Set the most suitable bowl speed got from step 1. The most suitable conveyor speed from step 2, increase pump flow from 5m3/h. Increase it more and more, like, 5cbm, 8cbm, 10cbm, 15cbm, 18cbm, 20cbm, and compare the performance, to find the most suitable performance you want get.

After the 3 stages, you will find out the best performance can come out from decanter centrifuge in the specified jobsite.

Remember: Every time the treating material changed, the centrifuge operator should repeat the 3 steps to find out the new centrifuge setting suitable for the new condition.

Decanter centrifuge is a physical separation machine. If the final result cannot satisfy you, that means physical treatment not enough, you may need chemical treatment or combined with other process.

- Details

-

Published: 30 August 2014