Zero-Discharge System has became the trend of drilling waste management Dilled cuttings and the waste drilling water should be disposed in a safe way to avoid the harm to sensitive environment. This is crucial to oil based drilling mud. A set up of one zero-discharge system contains the following parts:

1. Linear motion shale shakers to separate the drilling cuttings of size over 200 mesh from the drilling mud. The solids off the shakers are discharged over a screw conveyor to transport them to vertical cuttings dryer.

2. Vertical cuttings dryer is used to recover the oil from the drilling cuttings. The centrifugal force inside the dryer allows the liquid portion of the feed pass through the cake bed of solids while the cake bed itself is continuously sent to the discharge at the outer diameter of the screen basket. The “dried†cuttings exit from the front of the machine where they are discharged to another screw conveyor for further handling and treatment. The recovered oil exists tangentially from the base of the unit into a holding tank.

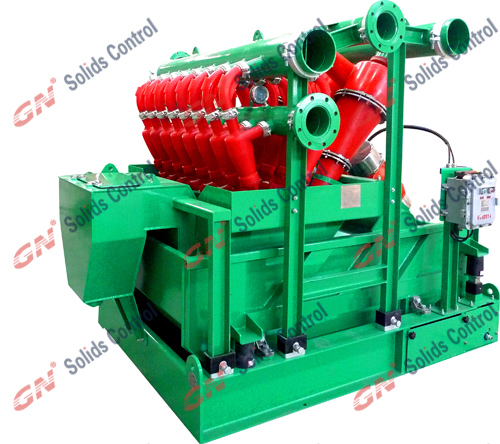

3. Centrifugal pumps feed the desander cone and desilter cones of the mud cleaner. The overflow discharge and the screen undersize are sent to the next compartment on the mud tank system. The cuttings with size over 250 mesh discharged by the mud cleaner screen are sent to the cuttings dryer.

4. Progressive displacement pump (PDP) feeds the low-speed decanter centrifuge to recover the barite. The effluent is then fed to the high-speed decanter centrifuge to separate the colloidal particles from the drilling fluid. This fluid is mixed with the liquid from the cuttings dryer discharge.

5. The effluent from the high-speed centrifuge is mixed with the barite from the low-speed centrifuge and returned to the mud system with a centrifugal pump.

GN centrifuge provide you with efficient centrifugal separation technology both in the horizontal and vertical types of centrifuges.

- Details

-

Published: 30 March 2014